Vertical powder material metering and filling device

A technology for powder materials and filling devices, applied in solid materials, packaging, packaging protection, etc., can solve the problems of inability to use the weight loss method for measurement, inability to meet measurement requirements, and inability to install weighing systems, so as to eliminate the need for material stirring. Mechanism, structure simplification, equipment cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

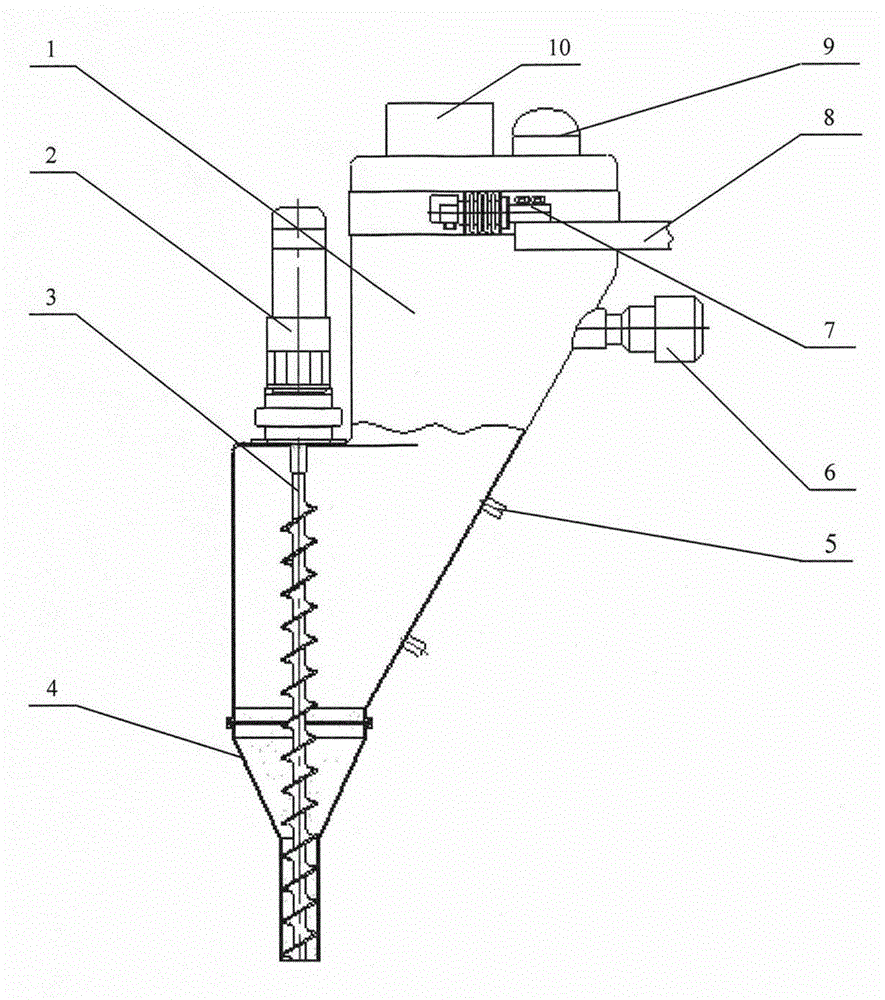

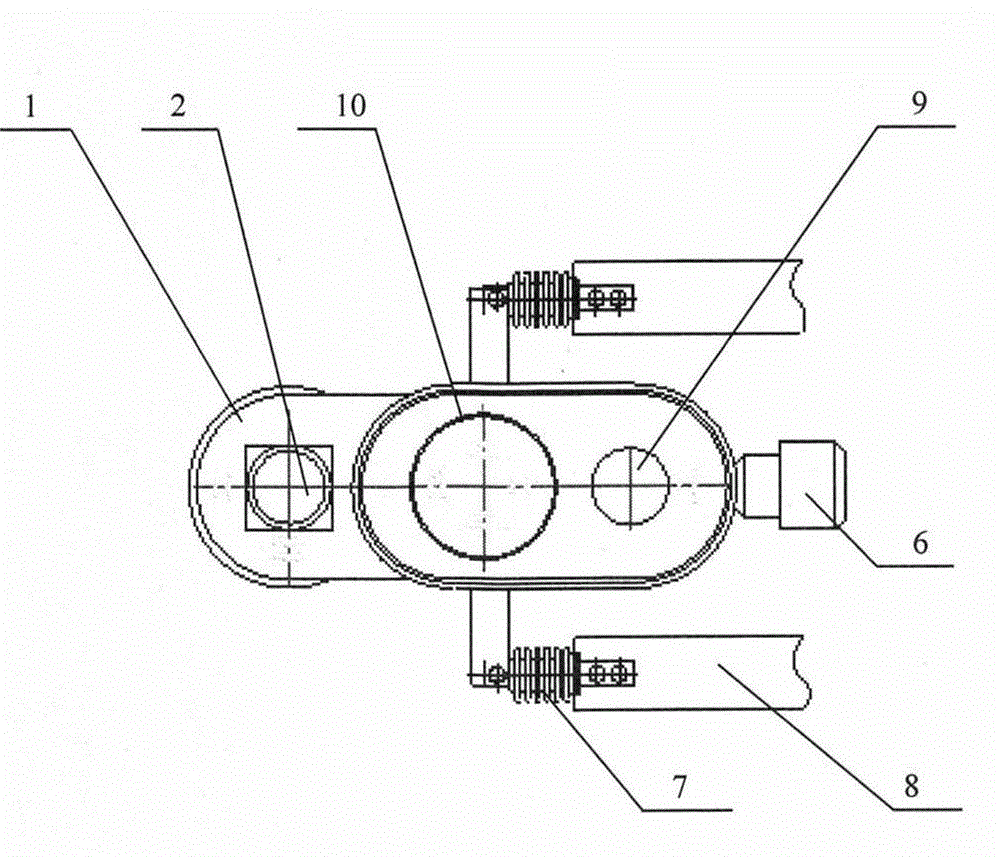

[0008] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

[0009] As shown in the accompanying drawing, this vertical powder material metering and filling device has a hopper 1. The two sides of the hopper 1 are planes. The back of the hopper 1 is a semi-cylindrical surface whose axis forms an angle of 55°~65° with the horizontal plane, and the top of the hopper 1 is a step plane with a first step plane and a second step plane placed above the first step plane. The motor shaft of a servo motor 2 is vertically installed on the first step plane of the hopper 1, the axis of the servo motor 2 coincides with the axis of the vertical semi-cylindrical surface at the lower front of the hopper 1, and the motor shaft of the servo motor 2 is coaxial Connect the feeding screw 3. A feeding pipe 4 is connected to the lower end of the hopper 1. The upper part of the feeding pipe 4 is an inverted conical pipe, and the lower part i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com