Thermal shrinkage seal cap air permeability test method and special test equipment

A technology of heat-shrinkable sealing caps and testing methods, which is applied in the testing of mechanical components, testing of machine/structural components, liquid-tightness measurement using liquid/vacuum degree, etc. It can solve the problems that the method is not applicable and difficult to implement , to achieve the effect of good test effect and strong operability

Pending Publication Date: 2017-09-15

FAR EAST CABLE +2

View PDF10 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

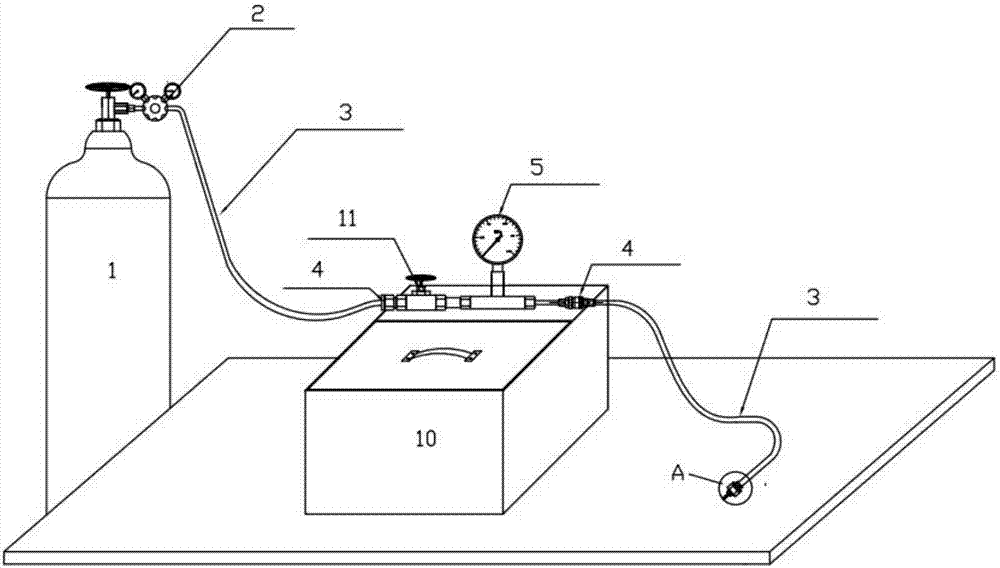

The current method is to prepare a metal tube, heat-seal a heat-shrinkable cap at both ends of it, immerse the lower end in water, open the air nozzle at the upper end to inflate, and judge by watching the pressure change of the pressure gauge and whether there is bubbles in the water Whether it is exhausted and under what pressure, it is necessary to equip metal tubes with suitable outer diameters for more than 40 specifications of heat shrinkable caps, and to connect a readable pressure gauge to metal tubes of various specifications. Not applicable and difficult to implement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0022] The air permeability test method of heat-shrinkable caps includes the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

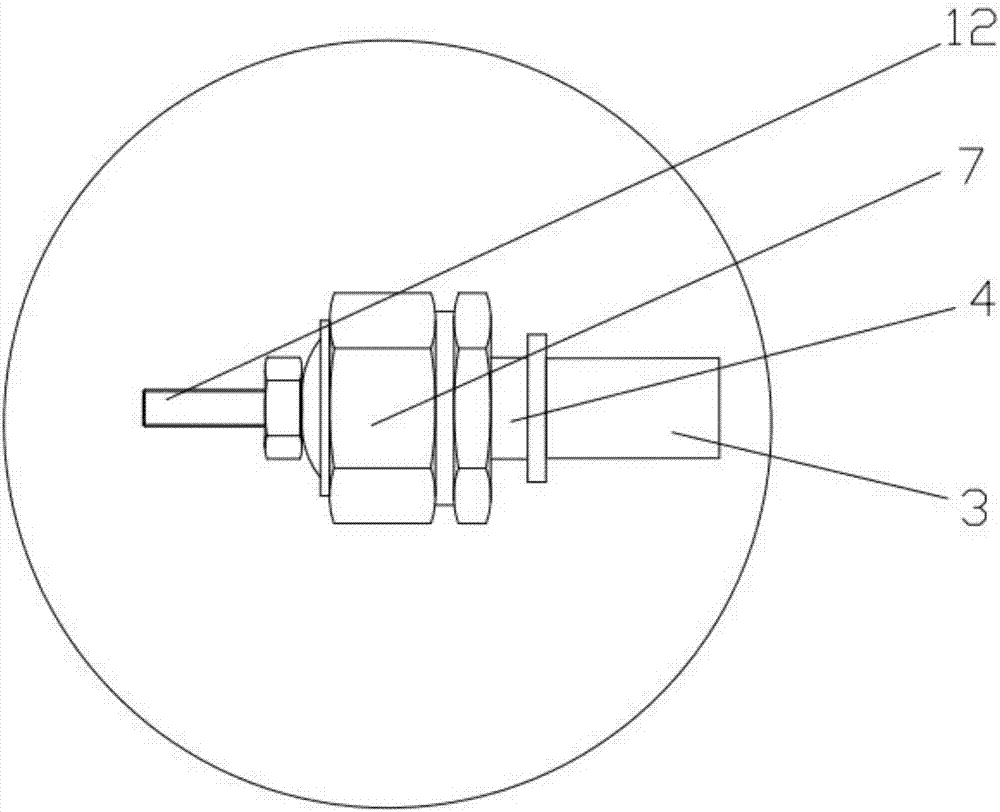

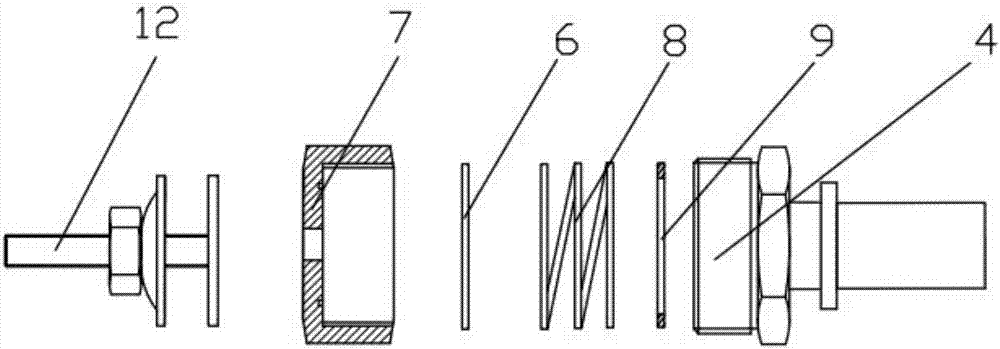

The invention discloses a thermal shrinkage seal cap air permeability test method and special test equipment. The method is characterized by, to begin with, carrying out water permeability test, and then, carrying out air permeability test; taking down a metal air nozzle of a thermal shrinkage seal cap sample passing the water permeability test, sleeving a seal ring and screwing and installing the metal air nozzle to a connector, and tightening a nut on the metal air nozzle; opening a master valve of a compressed air tank and a first pressure regulating valve, and fine tuning the first pressure regulating valve to ensure that a pointer of an air pressure gauge to still be zero; and adjusting the first pressure regulating valve on the air tank to enable the pressure pointer of the air pressure gauge to point 0.01 MPa, inserting a connecting pipe equipped with the metal air nozzle into water and observing whether the port of the metal air nozzle has bubbles coming out, if not, adjusting the pressure to 0.02 MPa, and if still no bubble coming out, judging that the air permeability of the seal cap is not qualified. The method does not need heat sealing in the test process, nor need to prepare a variety of specifications of metal pipes, and is high in operability and good in test effect.

Description

technical field [0001] The invention relates to a method for testing the air permeability of a heat-shrinkable sealing cap and special testing equipment. Background technique [0002] Heat-shrinkable sealing caps for cables include heat-shrinkable sleeves, gas nozzles and gas caps, which are packaged at the ends of medium and high-voltage cables. When inert gas appears in the cable and the gas reaches a certain pressure, the sealing cap gas nozzle can automatically exhaust. To protect the cable and avoid swelling. Therefore, the gas permeability of the heat shrinkable cap is very important to realize its function, but there is no relevant effective method for it at present. The current method is to prepare a metal tube, heat-seal a heat-shrinkable cap at both ends of it, immerse the lower end in water, open the air nozzle at the upper end to inflate it, and judge by watching the pressure change of the pressure gauge and whether there is bubbles in the water Whether it is e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M13/00G01M3/04

CPCG01M3/04G01M13/00

Inventor 蒋华娟徐静蒋洪平王艳洁

Owner FAR EAST CABLE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com