Polypropylene melt index hybrid modeling method based on integrated neural network

A melt index, neural network technology, applied in biological neural network models, neural learning methods, comprehensive factory control, etc., can solve problems such as low accuracy, large melt index prediction time lag, and poor extrapolation ability of pure data-driven models , to achieve the effect of reducing specific requirements, improving prediction accuracy, good prediction accuracy and generalization performance

Inactive Publication Date: 2017-09-15

ZHEJIANG UNIV OF TECH

View PDF2 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention overcomes the disadvantage of large time lag in the prediction of melt index in the production process of polypropylene in the prior art, and adopts an integrated neural network model in order to overcome the shortcomings of the existing pure mechanism model with low precision and pure data-driven model with poor extrapolation ability Carry out the error compensation of the mechanism model, establish a hybrid model of parallel structure, and then provide a polypropylene melt index hybrid modeling method based on integrated neural network

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

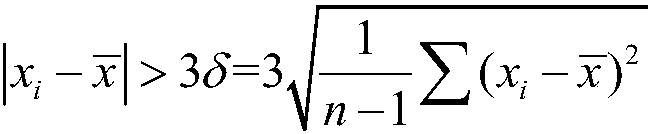

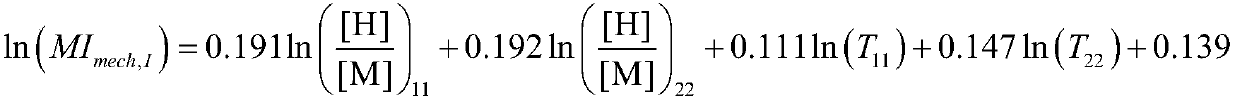

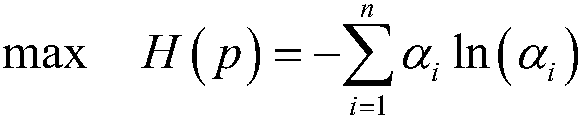

The invention discloses a polypropylene melt index hybrid modeling method based on an integrated neural network. The method comprises steps: firstly, through acquiring key process variable data and melt index offline analysis data, preprocessing such as outlier detection and standardization is carried out on original data, and a training sample data set is built; then, a mechanism analysis method and a steepest descent method are adopted to build a polypropylene melt index simplified mechanism model, and a Bagging ensemble learning algorithm and an information entropy method are adopted to build a mechanism model prediction error compensation model based on an integrated BP neural network; and finally, the simplified mechanism model and the error compensation model are combined, the error compensation model is built for realizing online melt index estimation. Compared with current other modeling methods, the method of the invention has the advantages that the model generalization performance is improved; the polypropylene production process can be guided; and the polypropylene quality control can be effectively realized.

Description

A Polypropylene Melt Index Hybrid Modeling Method Based on Integrated Neural Network technical field The invention belongs to the field of soft sensor modeling and application in the chemical production process, and in particular relates to a method for modeling the melt index mixing of polypropylene production process based on integrated neural network. Background technique In the production process of polypropylene, there are problems such as unstable product quality and few special materials. This requires polypropylene production enterprises to carry out industrial upgrading as soon as possible, and develop in the direction of large-scale, catalyst diversification and process control automation. Melt index is one of the most important quality indicators in the production process of polypropylene, which is used to distinguish different grades of polypropylene products. At present, in the production process of polypropylene, the melt index can only be obtained through re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G05B19/418G06N3/08

CPCY02P90/02G05B19/41885G05B2219/32339G06N3/084

Inventor 夏陆岳潘海天王海宁

Owner ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com