Divalent metal ion pre-intercalation layered vanadium oxide nanomaterial and its preparation method and application

A technology of divalent metal ions and vanadium oxides, which is applied in the fields of nanomaterials and electrochemistry, and can solve problems such as unreported research work on preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

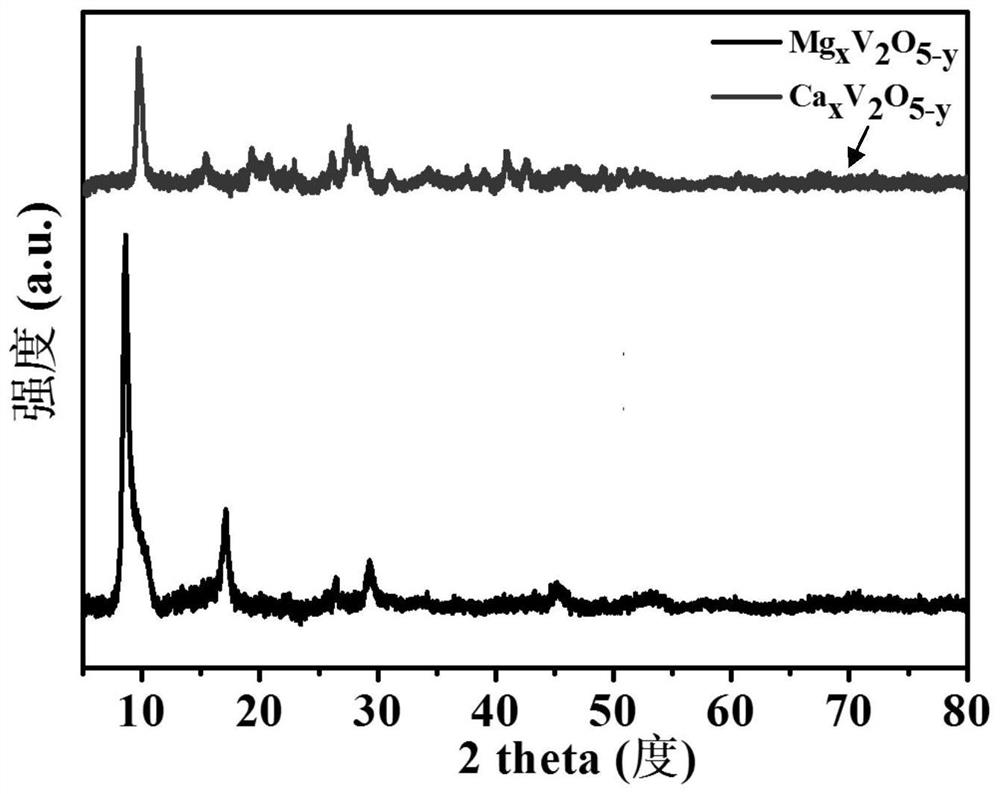

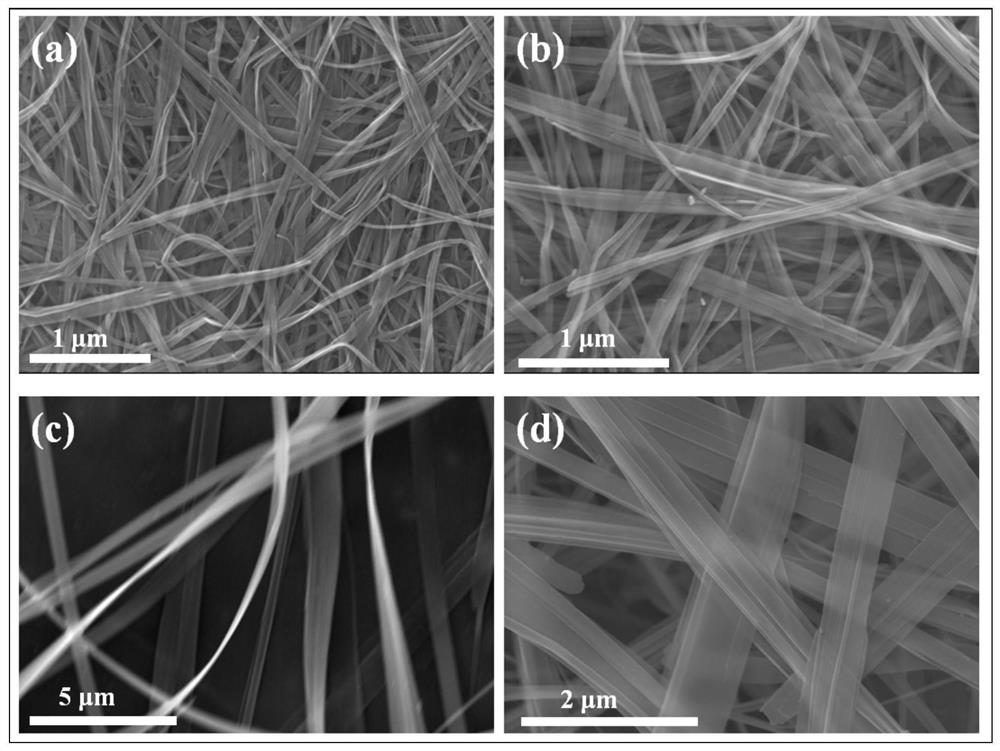

Embodiment 1

[0030] Mg x V 2 o 5-y The preparation method of nanoribbon material, it comprises the steps:

[0031] 1) Weigh 4 parts of 0.364g V respectively 2 o 5 Add it to 30ml of deionized water, and add 5ml of 30% H 2 o 2 solution, magnetically stirred for half an hour to obtain an orange-red clear solution;

[0032] 2) Weigh 50mmol, 100mmol, 150mmol, and 200mmol MgCl 2 .6H 2 O, while magnetically stirring, add to the orange-red clear solution in step 1) respectively, will be accompanied by a violent exothermic reaction, a large amount of orange-red flocculent precipitates will be produced, and continue to stir for 2 to 4 hours;

[0033] 3) Transfer the suspension containing flocculent precipitate obtained in step 2) to a 50ml reaction kettle, and heat it at 200° C. for 4 days. Then take it out and cool it down to room temperature naturally to obtain dark green, yellow, orange red and red products respectively;

[0034] 4) Pour the product of step 3) into a beaker, mash it, ad...

Embodiment 2

[0040] Ca x V 2 o 5-y A preparation method for a nanowire material, comprising the steps of:

[0041] 1) Weigh 0.364g V 2 o 5 Add it to 30ml of deionized water, and add 5ml of 30% H 2 o 2 solution, magnetically stirred for half an hour to obtain an orange-red clear solution;

[0042] 2) Weigh 100mmol CaCl 2 , and adding it into the orange-red clear solution in step 1) while magnetically stirring, will be accompanied by a violent exothermic reaction, and a large amount of orange-red flocculent precipitates will be produced. Stirring was continued for 2-4 hours.

[0043] 3) Transfer the suspension containing flocculent precipitate obtained in step 2) to a 50ml reaction kettle, and heat it at 200° C. for 4 days. Then take out and cool to room temperature naturally to obtain orange-red product;

[0044] 4) Pour the product of step 3) into a beaker, mash it, add 30-50ml of deionized water, and stir it magnetically to form a uniform suspension;

[0045] 5) The suspension ...

Embodiment 3

[0048] Sr x V 2 o 5-y The preparation method of nanowire, it comprises the steps:

[0049] 1) Weigh 0.364g V 2 o 5 Add it to 30ml of deionized water, and add 5ml of 30% H 2 o 2 solution, magnetically stirred for half an hour to obtain an orange-red clear solution;

[0050] 2) Weigh 100mmol SrCO 3 Add it into the orange-red clear solution in step 1) while magnetically stirring, and the solution will turn into light brown with a violent exothermic reaction. Continue to stir for 2 to 4 hours to obtain a brown clear solution.

[0051] 3) Transfer the suspension containing flocculent precipitate obtained in step 2) to a 50ml reaction kettle, and heat it at 200° C. for 4 days. Then take out and naturally cool to room temperature to obtain a dark green product;

[0052] 4) Pour the product of step 3) into a beaker, mash it, add 30-50ml of deionized water, and stir it magnetically to form a uniform suspension;

[0053] 5) The suspension obtained in step 4) is subjected to ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com