Novel waterproof shell for fuel cell

A fuel cell and waterproof case technology, which is applied to fuel cell components, fuel cell additives, fuel cell heat exchange, etc., can solve problems affecting water resistance and fuel cell use, and achieve increased service life and simple structure , Good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

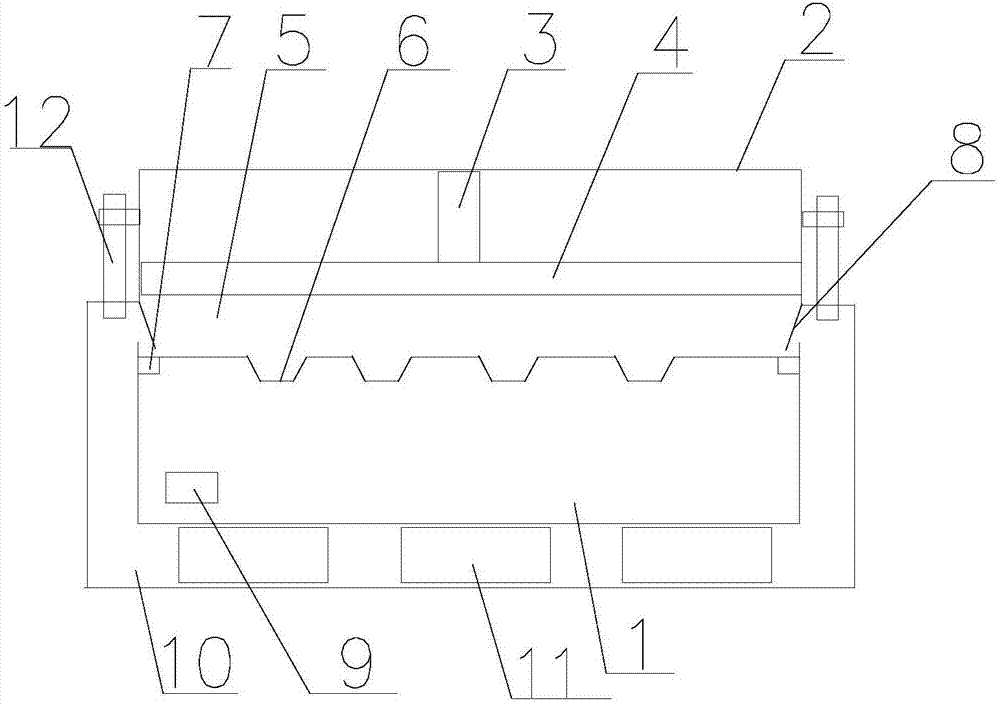

[0024] Such as figure 1 As shown, the novel waterproof case for fuel cells of the present invention includes a placement chamber 1 for accommodating fuel cells, the upper opening of the placement chamber 1 is connected with a heat dissipation chamber 2, and the heat dissipation chamber 2 is from top to bottom In turn, it includes a telescopic telescopic rod 3, an extrusion plate 4 connected to the telescopic rod 3 that can slide along the inner wall of the heat dissipation chamber 2, the lower end of the heat dissipation chamber 2 is located above the placement chamber 1, and the bottom of the heat dissipation chamber 2 has several Through hole 6, the air can flow into the placement chamber 1 from the heat dissipation chamber 2 through the through hole 6. There are several small through holes at the bottom of the placement chamber 1, and a heat dissipation channel 10 is connected to the bottom of the placement chamber 1. There are openings at both ends of the heat dissipation ...

Embodiment 2

[0026] The novel waterproof casing for fuel cells includes a placement cavity 1 for accommodating fuel cells, the top of the placement cavity 1 is open and connected with a heat dissipation cavity 2, and the heat dissipation cavity 2 includes sequentially from top to bottom A telescopic telescopic rod 3, an extruding plate 4 connected to the telescopic rod 3 and able to slide along the inner wall of the heat dissipation chamber 2, the lower end of the heat dissipation chamber 2 is located above the placement chamber 1, and the bottom of the heat dissipation chamber 2 has several through holes 6. The air can flow from the heat dissipation chamber 2 into the placement chamber 1 through the through holes 6. There are several small through holes at the bottom of the placement chamber 1, and a heat dissipation channel 10 is connected to the bottom of the placement chamber 1. The heat dissipation There are openings at both ends of the channel 10, and the openings are connected to the...

Embodiment 3

[0028] The novel waterproof casing for fuel cells includes a placement cavity 1 for accommodating fuel cells, the top of the placement cavity 1 is open and connected with a heat dissipation cavity 2, and the heat dissipation cavity 2 includes sequentially from top to bottom A telescopic telescopic rod 3, an extruding plate 4 connected to the telescopic rod 3 and able to slide along the inner wall of the heat dissipation chamber 2, the lower end of the heat dissipation chamber 2 is located above the placement chamber 1, and the bottom of the heat dissipation chamber 2 has several through holes 6. The air can flow from the heat dissipation chamber 2 into the placement chamber 1 through the through holes 6. There are several small through holes at the bottom of the placement chamber 1, and a heat dissipation channel 10 is connected to the bottom of the placement chamber 1. The heat dissipation There are openings at both ends of the channel 10, and the openings are connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com