Cold plate and refrigerating system with same

A cold plate and refrigerant technology, applied in the field of heat transfer and refrigeration, can solve the problems of limited jet cooling effect, limited pressurization capacity, powerlessness, etc., achieve good heat transfer effect, compact structure, and enhanced surface evaporation exchange The effect of heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

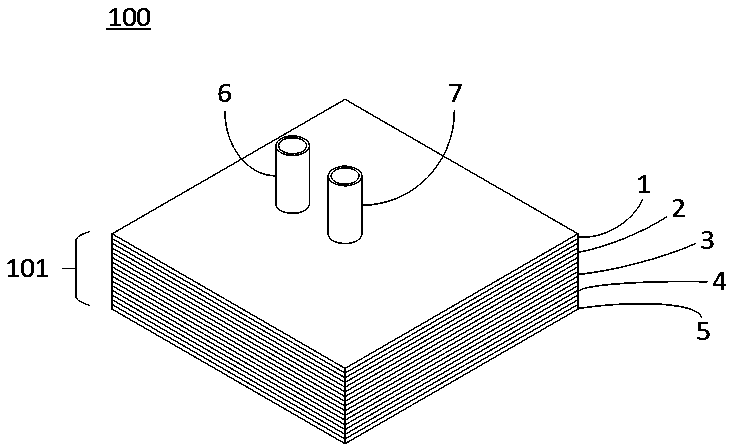

[0031] The embodiment of the first aspect of the present invention provides a cold plate, such as Figure 1~Figure 8 shown.

[0032] Such as figure 1 Shown is the appearance of the cold plate 100 . The cold plate 100 is formed by stacking five types of plates (typically metal sheets with a thickness less than 1 mm) in a certain order and number of plates with different hollow shapes, and then through a certain method of bonding between plates. Multi-layer solid 101 , then inlet pipe 6 and outlet pipe 7 are installed on multi-layer solid 101 .

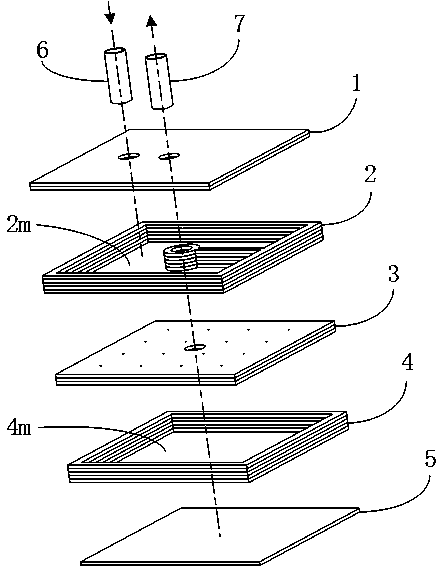

[0033] Such as figure 2 Shown is a schematic diagram of the stacking sequence and positional relationship of each plate before the five types of plates of the cold plate and the fluid inlet and outlet joints are not combined into a whole, and the assembly relationship with the fluid inlet and outlet pipes ( explosion diagram).

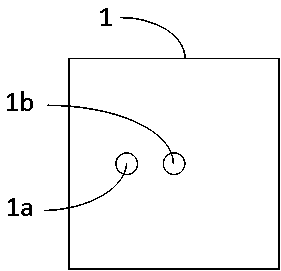

[0034]The five types of plates constituting the multi-layer entity 101 are: the upper cover plate 1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com