Electronic module and manufacturing method thereof

A technology of electronic modules and electronic components, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems affecting the characteristics of electronic components, reducing performance, and failure of electronic components, achieving both heat dissipation effect and increased surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

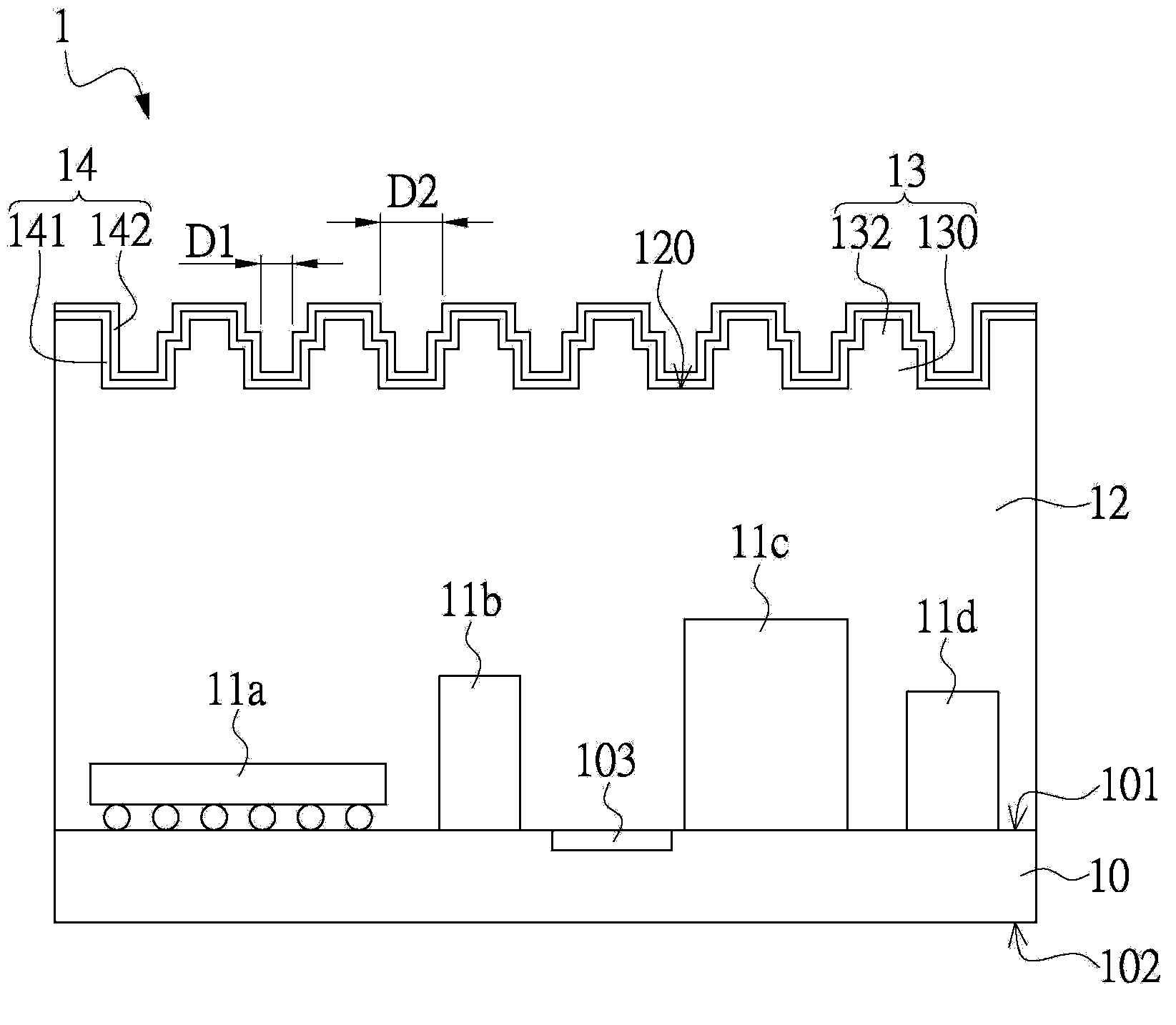

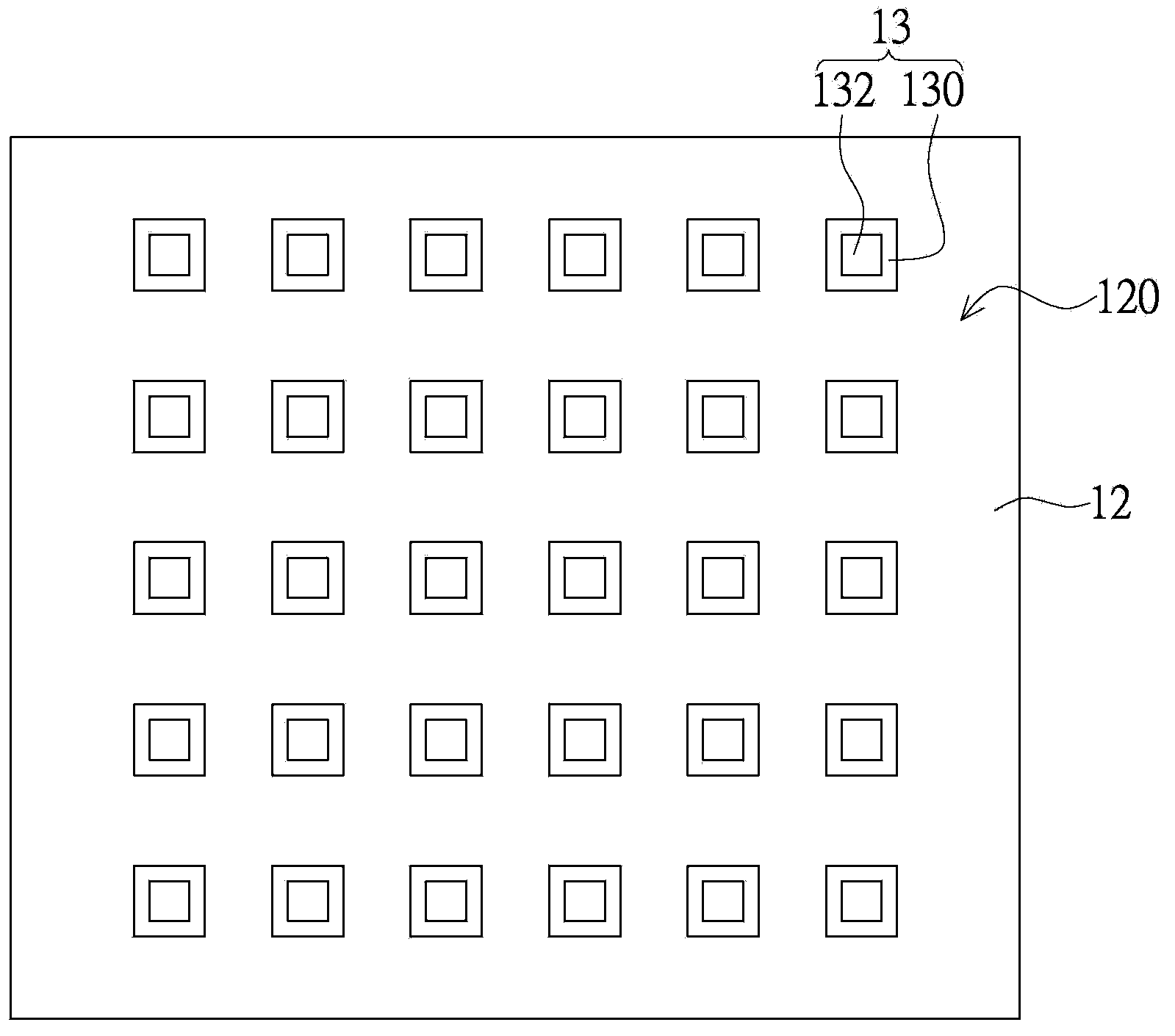

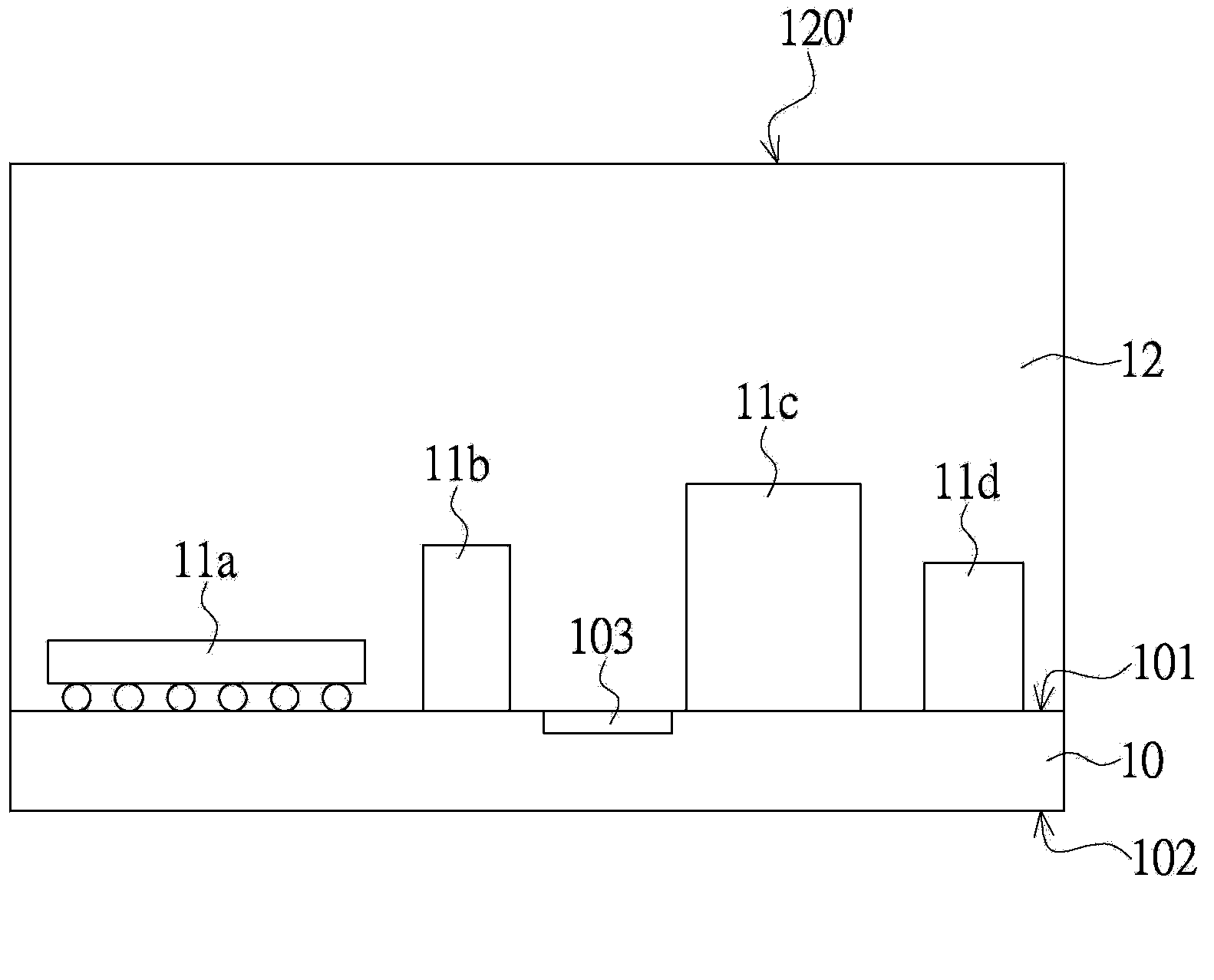

[0040] Please refer to figure 1 . figure 1 A cutaway side view of an electronic module according to an embodiment of the present invention is shown. The electronic module 1 includes a substrate 10 , electronic components 11 a - 11 d , a molding layer 12 and a composite electromagnetic wave shielding layer 14 .

[0041] The substrate 10 has a carrying surface 101 and a bottom surface 102 . The substrate 10 also has a plurality of preset pads 103 and circuit layers (not shown). The pad 103 is made of conductive material, such as copper, to be electrically connected to a conductive circuit (not shown) or a ground plane (not shown). Wherein, the pads 103 and the circuit layer (not shown) are located on the substrate 10 or buried in the substrate 10 . The material of the substrate 10 can vary according to the process and product requirements. For example, the semiconductor industry is a silicon-containing semiconductor wafer, and in other applications, it can be a PCB substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com