Bus duct power distribution device

A technology of power distribution device and busway, which is applied in the direction of semi-closed busbar device, etc., can solve the problems of complex structure of connection part, low work efficiency, large installation space, etc., so as to facilitate large-scale production and sales, and increase production efficiency , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

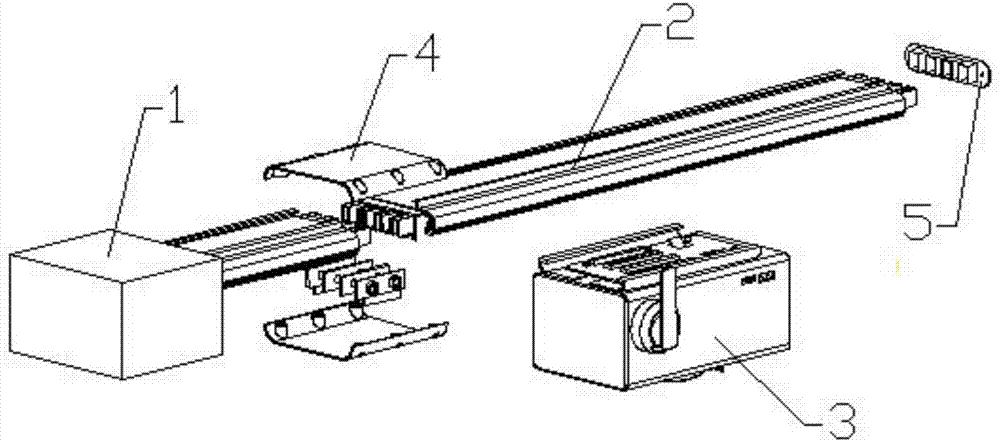

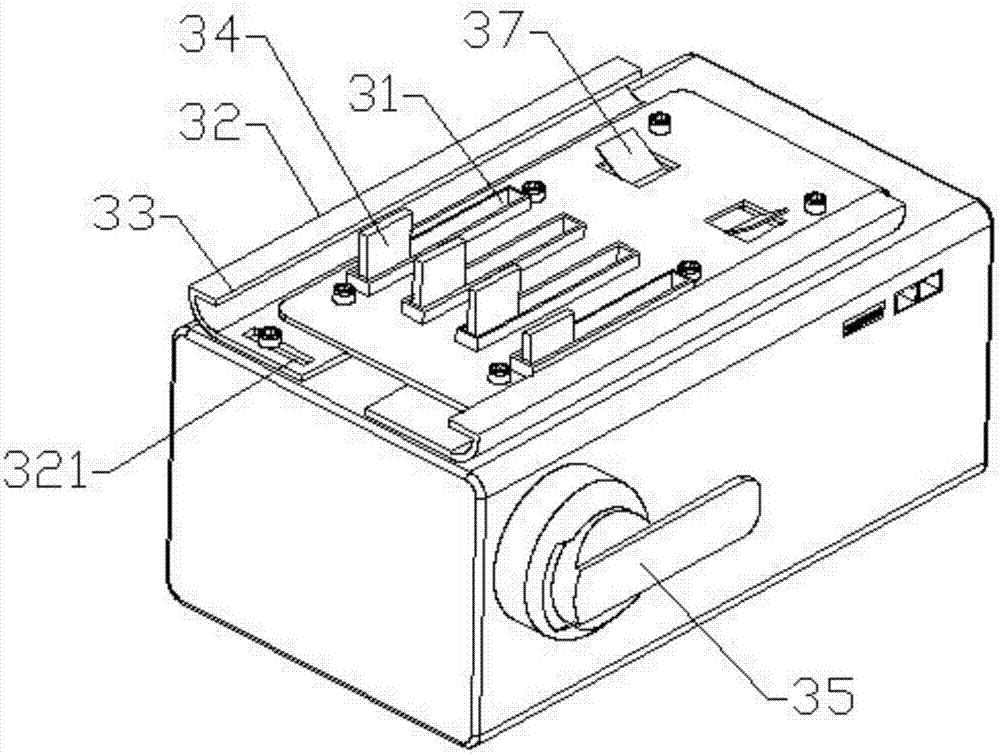

[0024] Such as Figure 1-6 and Figure 8 As shown, the present invention proposes a bus duct power distribution device, including a port box 1 for power supply, a bus duct body 2 connected to the port box 1 to transmit current, and a bus duct body connected to the bus duct body 2 to take out current. Plug-in box 3, wherein:

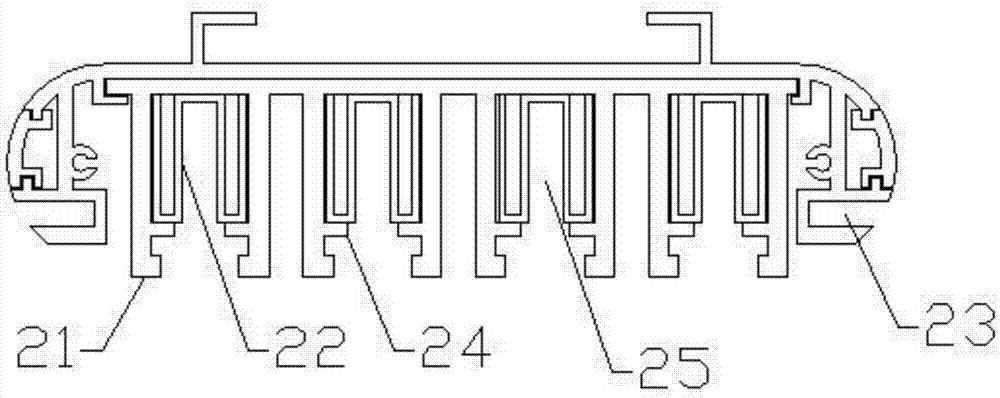

[0025] The bus duct body 2 is an inverted trough structure with an opening on the lower side, and inward card slots 23 are arranged on both side walls, and an insulating bracket 21 is arranged inside the bus duct body 2 along the direction of the channel. The top of the support 21 is connected to the inner wall of the channel. The insulating support 21 includes several conductor accommodation cavities 25 arranged side by side along the direction of the channel. In this embodiment, the number of conductor accommodation cavities 25 is four. , a symmetrical protrusion 24 is formed inward near the bottom end, and a conductor 22 with a "Π"-shaped cross secti...

Embodiment 2

[0032] Such as Figure 7 As shown, the content of this embodiment is basically the same as that of Embodiment 1, the difference is that the transmission device 36 includes a connecting rod 364 of the vertical conductive sheet 34, the connecting rod 364 is fixedly connected with the joystick 35, and the connecting rod 364 is connected with a connection bracket 365, the connection bracket 365 is detachably connected with the conductive sheet 34 one by one, and when the joystick is rotated 35, the connecting rod 364 is driven, so that the conductive sheet 34 is directly driven to rotate through the connection bracket 365, and the conduction is completed. Snap-in or snap-off operation between the tab 34 and the conductor 22 .

Embodiment 3

[0034] Such as Figure 9 As shown, the content of this embodiment is basically the same as that of Embodiment 1, except that the conductor 22 has an inward flanging structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com