A method for predicting the chemical composition of the finished product of reconstituted tobacco leaves by papermaking process with tobacco stem pretreatment

A technology of tobacco stem pretreatment and chemical composition, applied in the fields of tobacco, tobacco preparation, food science, etc. Handling process and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

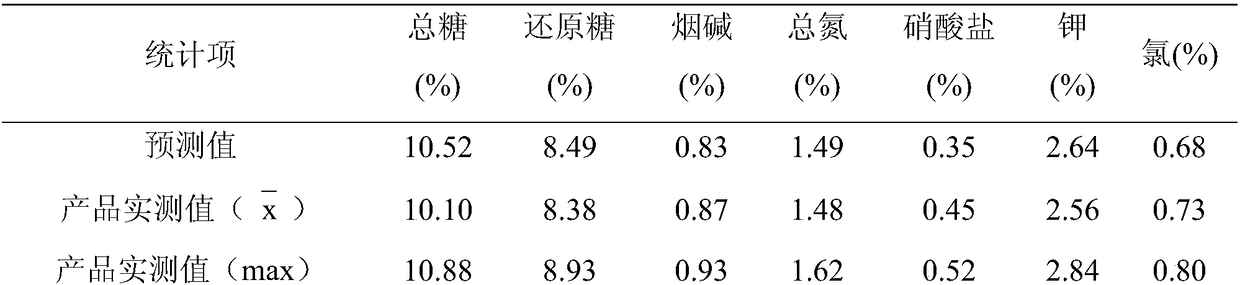

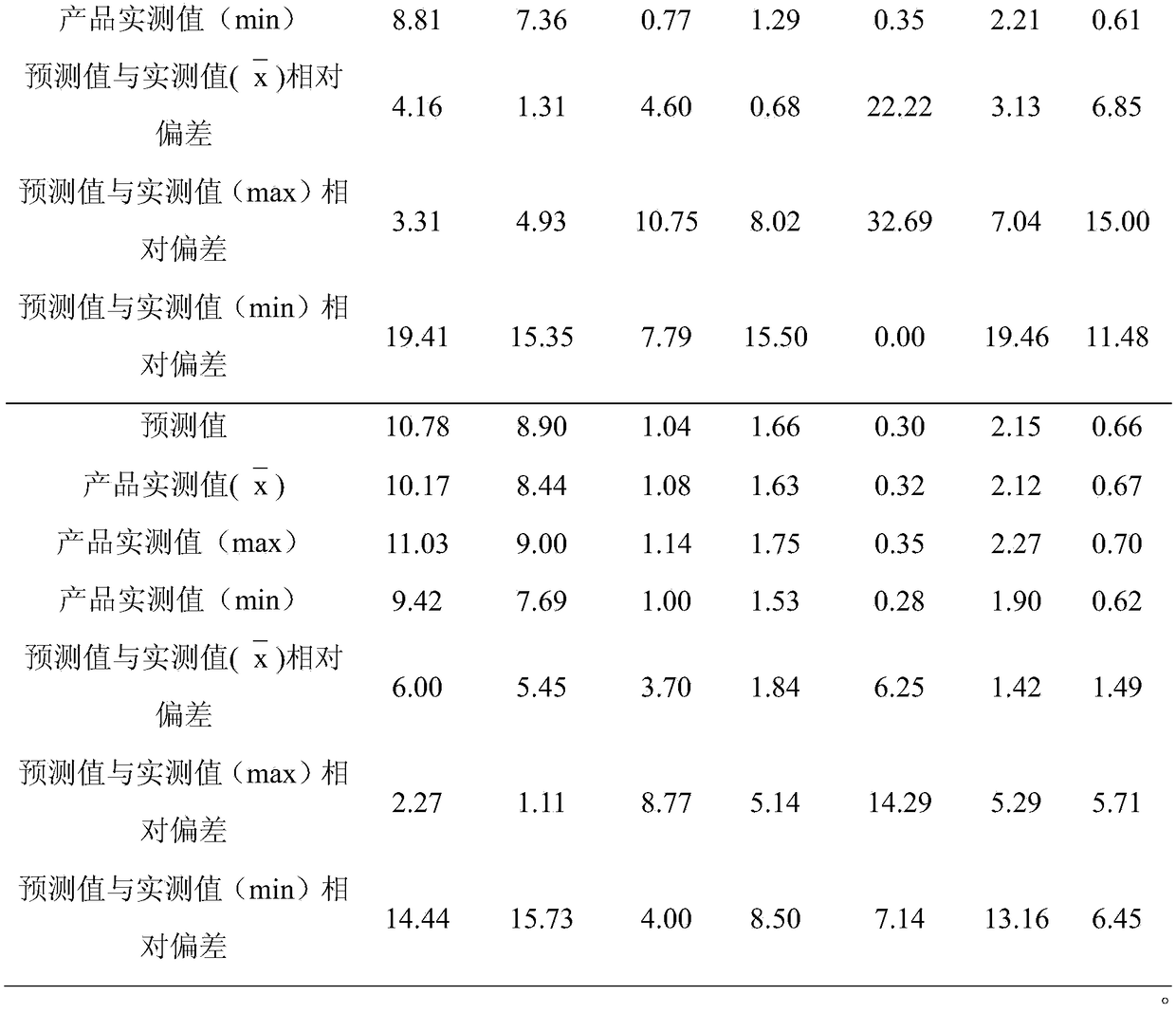

[0027] A method for predicting the chemical composition of finished paper-making reconstituted tobacco leaves containing tobacco stem pretreatment, comprising:

[0028] Obtain the content of chemical components after the tobacco stem pretreatment process;

[0029] Obtain the chemical composition content of the reconstituted tobacco leaf formula raw materials;

[0030] Input the chemical component content of the pretreated tobacco stem and the chemical component content of the raw material formula of the reconstituted tobacco leaf by papermaking method into the pre-generated retention rate and transfer rate model, and then use the retention rate and transfer rate model data to obtain the obtained after pretreatment of the tobacco stem. The chemical composition content and the value of the chemical composition content of the finished reconstituted tobacco leaf are corrected, and finally a prediction model for the chemical composition of the finished reconstituted tobacco leaf is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com