Portable on-site shaft turning device

A field car and portable technology, applied in turning equipment, feeding device, thread cutting device, etc., can solve the problems of difficult disassembly, time-consuming and laborious disassembly, and inability to disassemble, to shorten the construction period, avoid disassembly work, and reduce the weight of the equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

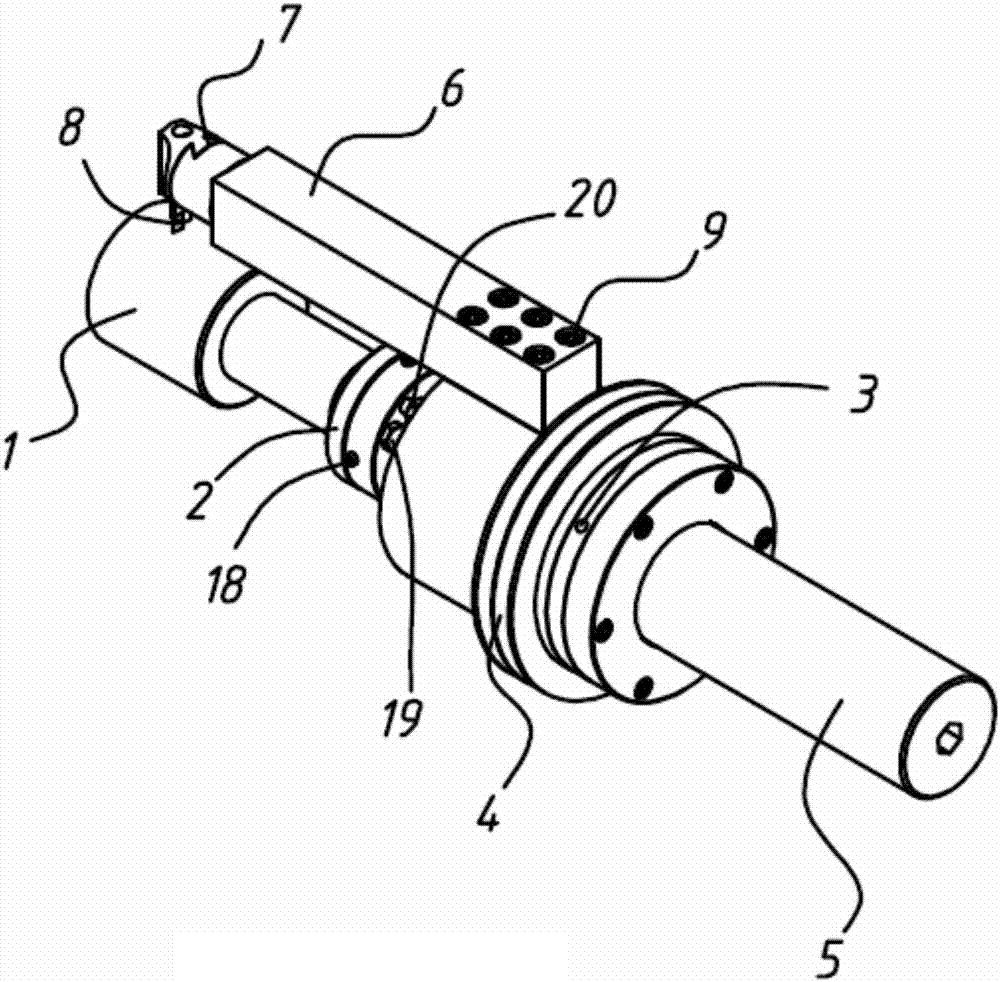

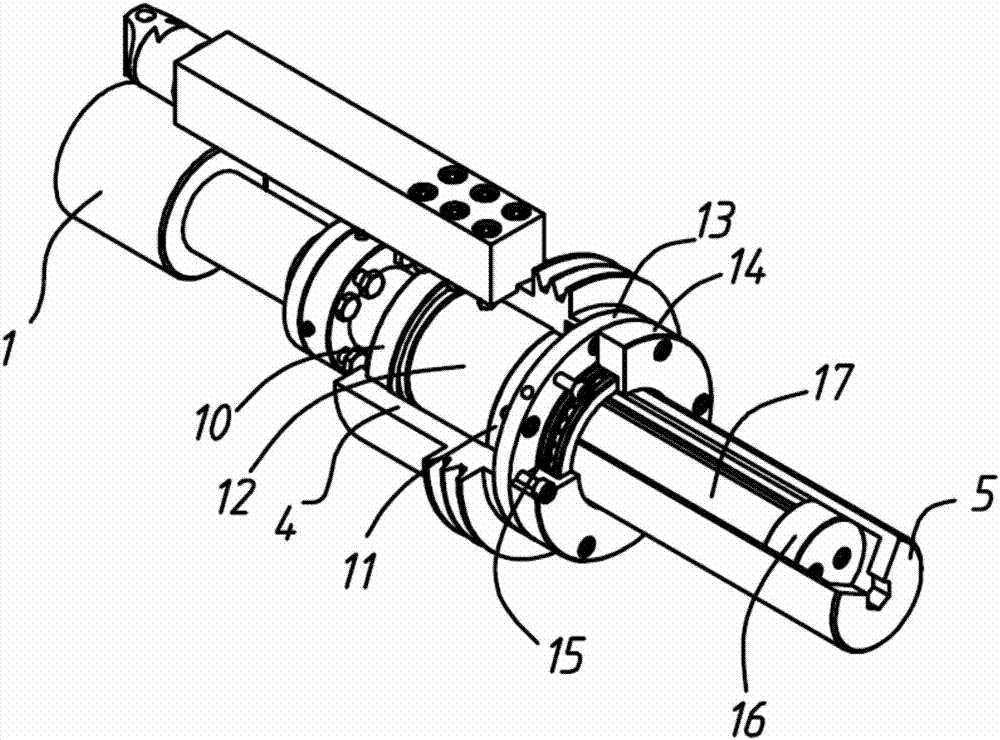

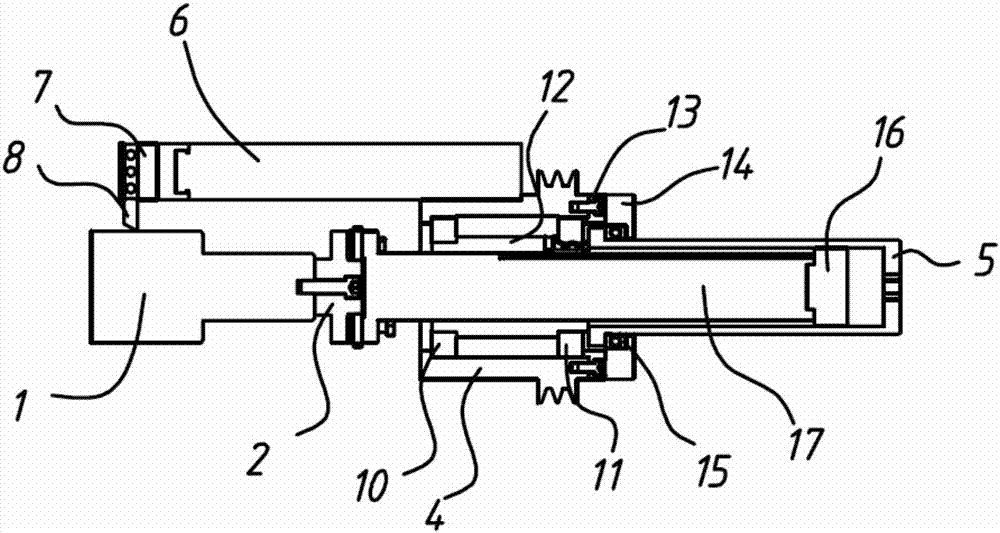

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] The equipment is driven by a power unit (motor, etc.) through a belt to drive the drive shaft sleeve 4 to rotate. There are bearings 10 and 11 between the drive shaft sleeve 4 and the main shaft sleeve 12. The tool bar 6 and the drive shaft sleeve 4 are fastened by bolts, so that Tool bar 6 and turning tool 8 rotate to realize circular turning motion. The main shaft 17 is fixedly connected with the workpiece 1, the main shaft sleeve 12 and the main shaft 17 are sliding fits, and there are guide keys, the end of the main shaft 17 is equipped with a feed nut 16, and the feed screw sleeve 5 is rotated by a wrench to realize the feed movement. Through the combination of the main rotation and the feed motion, the helical motion of the turning tool can be completed, and the outer circle turning can be completed. The bearing end cover 13 is connected with the feed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com