Overturning liquid-pouring device for honing machine reaming

A honing machine and reaming technology, which is used in honing machine tools, metal processing equipment, manufacturing tools, etc., can solve the problems of residual liquid and can not be collected completely, and achieve the effect of thorough dumping, cleanliness and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

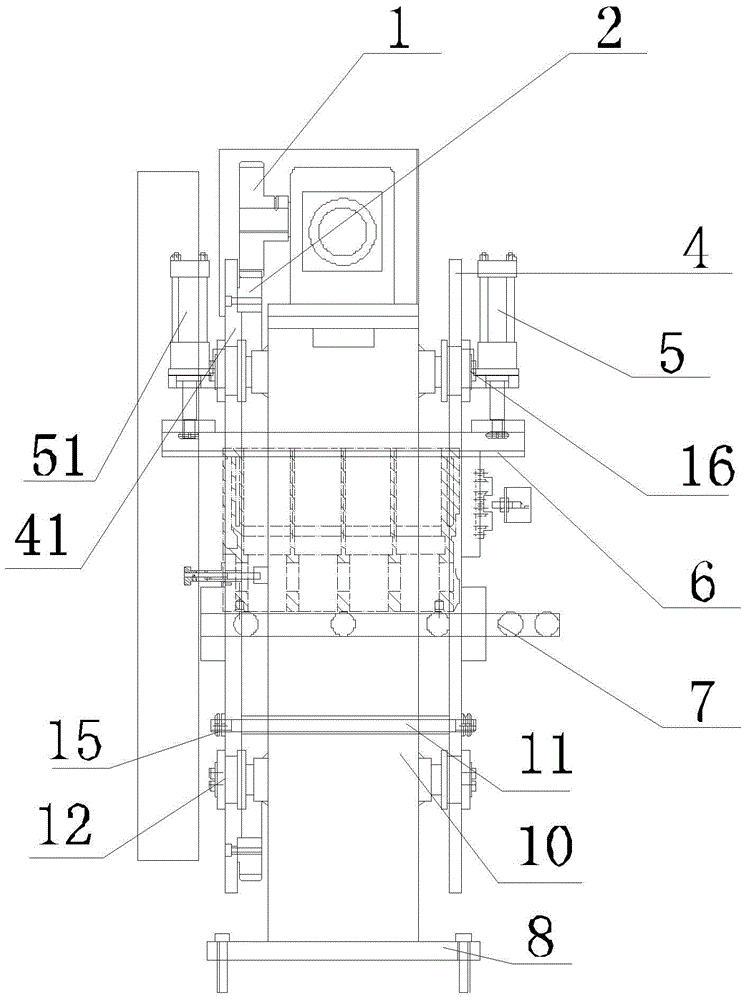

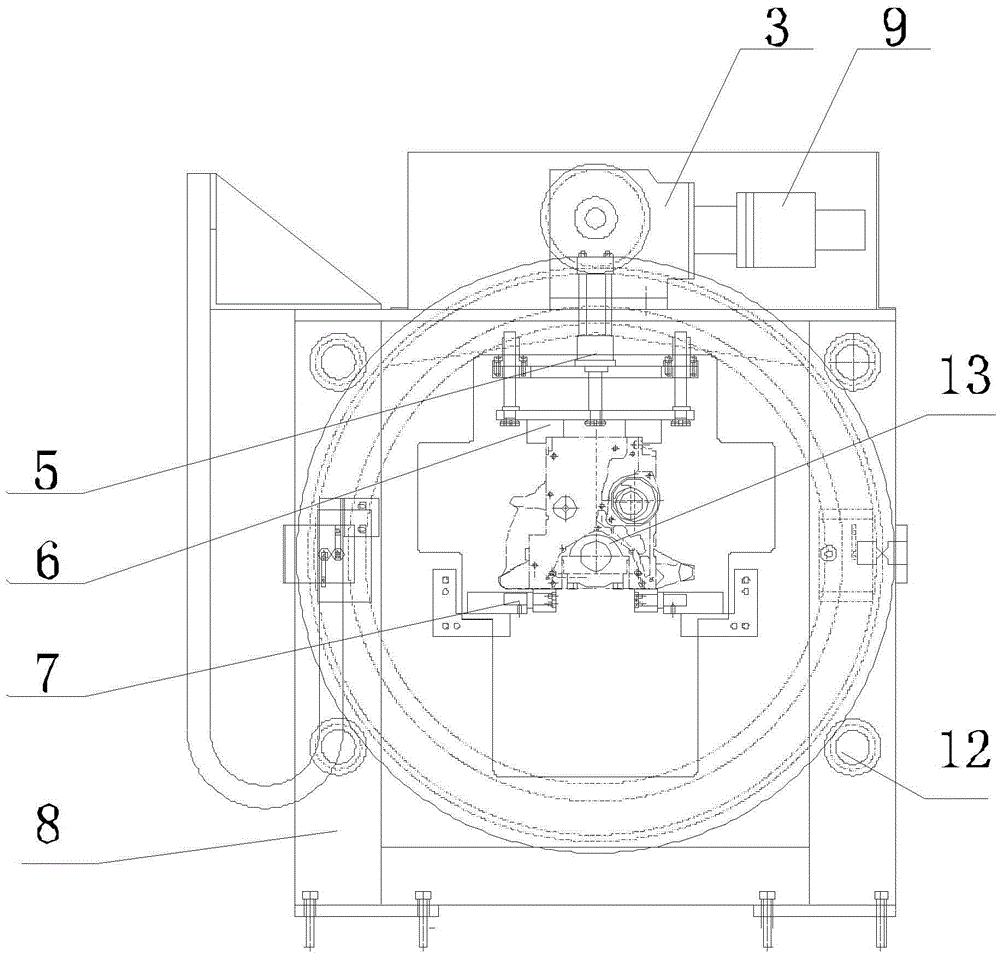

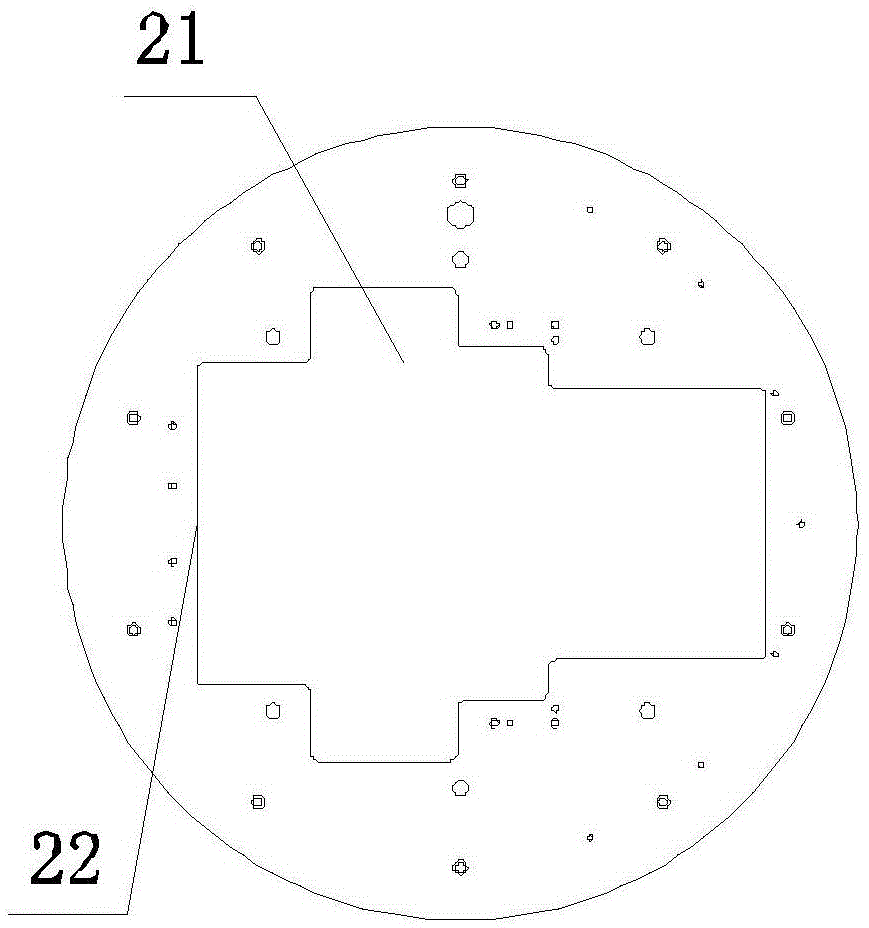

[0025] see Figure 1-2 As shown, the honing machine reaming device according to the embodiment of the present invention handles the honing liquid remaining in the engine block after the honing machine completes the reaming process of the engine block, and its function is mainly to collect the honing liquid, Save costs; collect honing fluid to ensure the cleanliness of workpieces and work sites.

[0026] The anti-rotation device for honing machine reaming in the embodiment of the present invention includes a bracket 8, a cylinder clamping mechanism arranged on the bracket 8, a turning mechanism for processing the honing fluid in the cylinder, and a drive for driving the turning mechanism mechanism. Wherein, the cylinder body clamping mechanism clamps the cylinder body in the vertical direction; the turning mechanism is arranged on the bracket 8, and driven by the driving mechanism, the cylinder body is turned over to realize the function of turning over and pouring liquid.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com