Method for penetrating I-steel transverse beam in reinforcing process of jacking bridge and culvert line

A technology of I-beams and beams, which is applied in the direction of road floors and buildings, can solve problems such as large traction, low work efficiency, and hidden dangers of railway traffic safety, and achieve the effects of ensuring traffic safety, improving labor efficiency, and speeding up the penetration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The method for passing down the I-beam beam during the reinforcement process of the jacking bridge and culvert line provided by the present invention will be described in detail below in conjunction with specific embodiments.

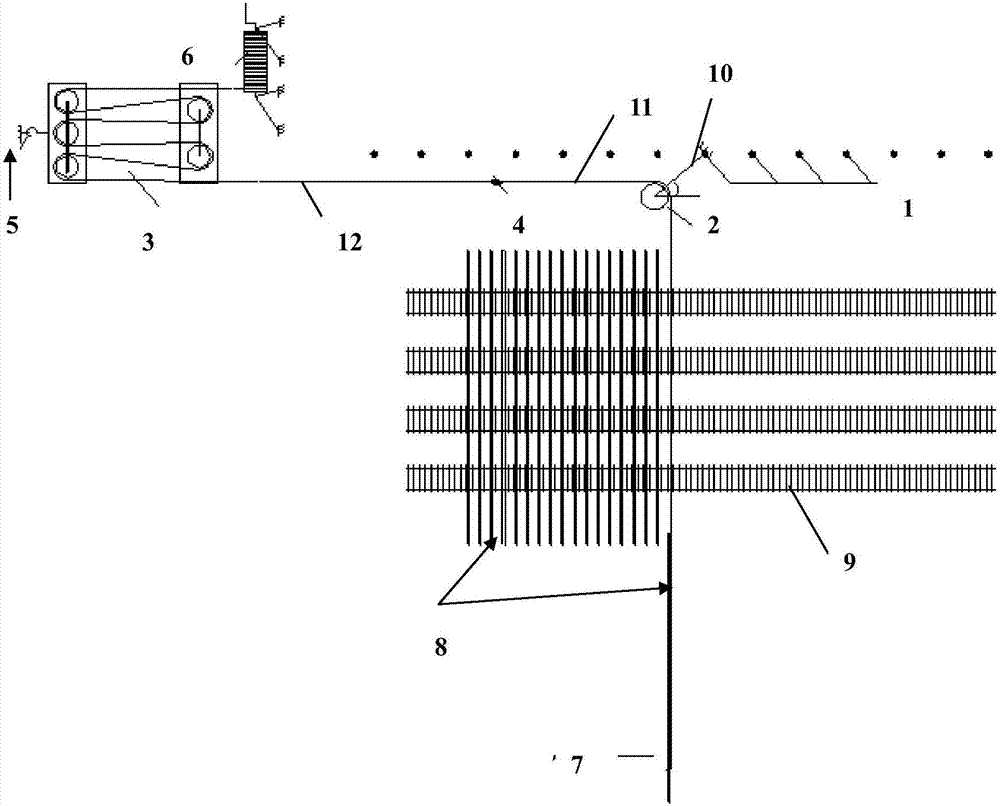

[0026] At the construction site of an tunnel bridge on the Beijing-Kowloon Line, the line level is Class I, and there are about 110 pairs of daily traffic. The existing line 9 is 2 groups of main lines and 2 groups of arrival and departure lines. The reinforcement range of the existing line 9 is 80m, and a total of 90 I-beams 8 pass under it, and the traveling distance of the I-beams 8 is 28m. This project adopts the method provided by the invention

[0027] The method for passing down the I-beam beam during the reinforcement process of the jacking bridge and culvert line provided by this embodiment includes the following steps in order:

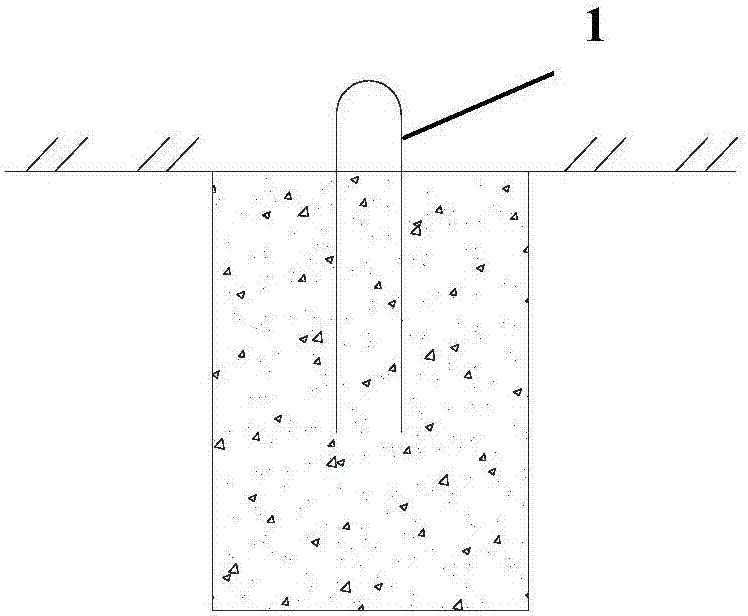

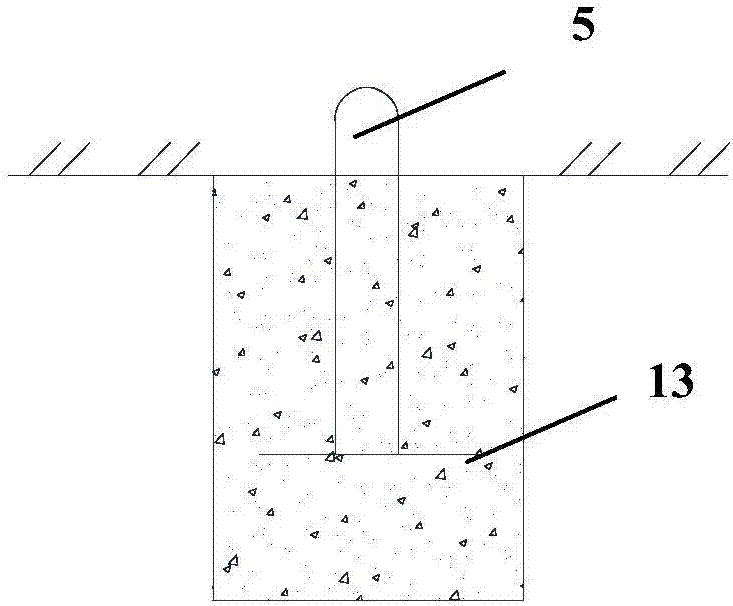

[0028] 1) A row of fixed pulley anchor piles 1 is evenly pre-embedded in the railway subgrade soil outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com