Coal mine gas drainage deep hole pre-splitting blasting anti-reflection device and method

A technology of pre-splitting blasting and coal mine gas, which is applied in the field of anti-reflection devices for deep hole pre-splitting blasting in coal mine gas drainage, to achieve the effects of ensuring property safety, shortening the charging time, and preventing coal mine gas outburst accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

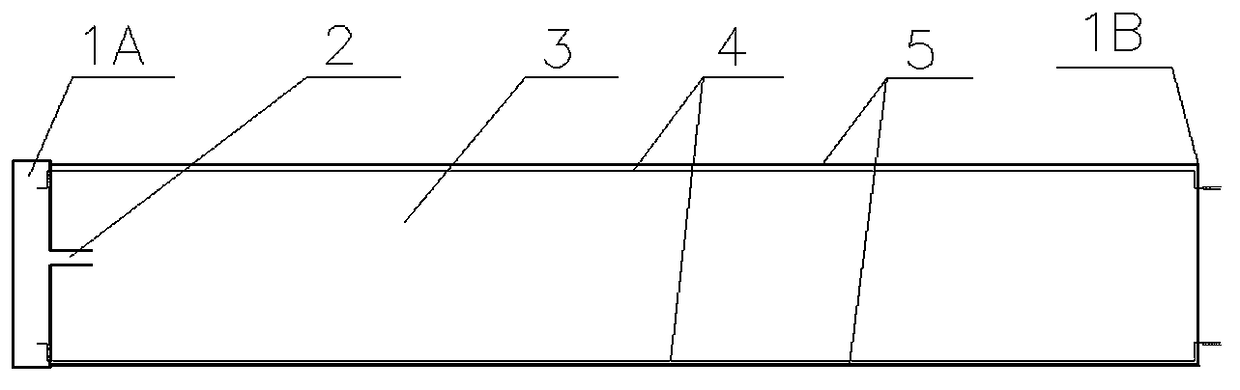

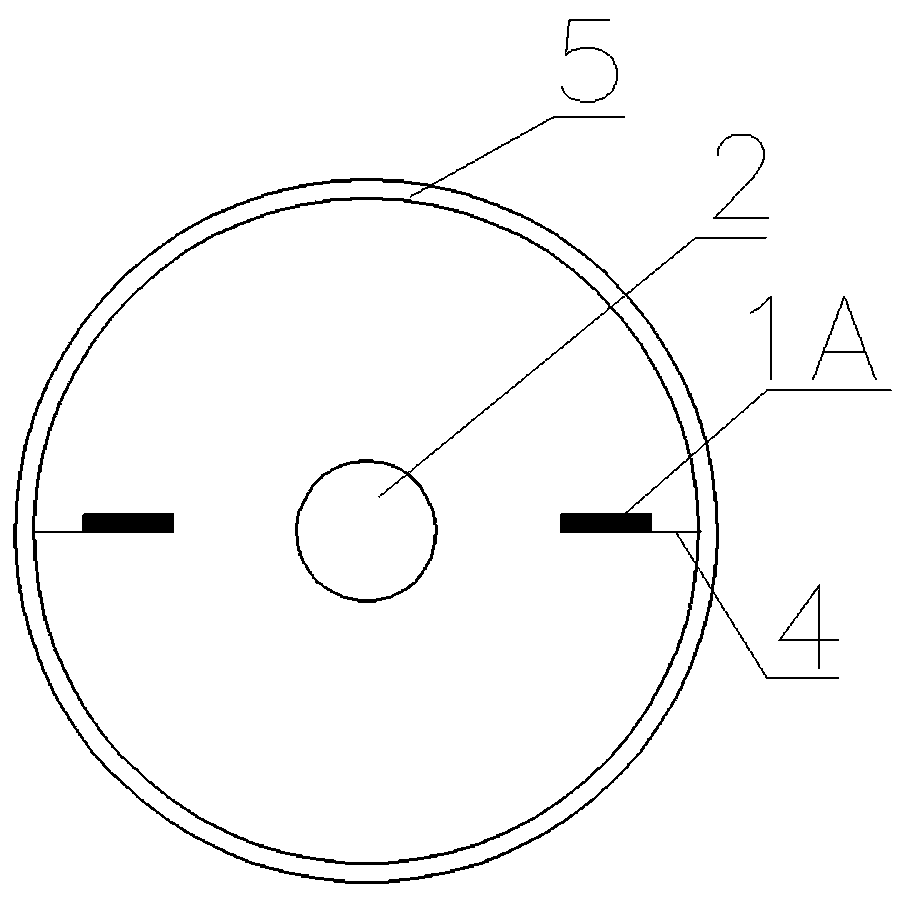

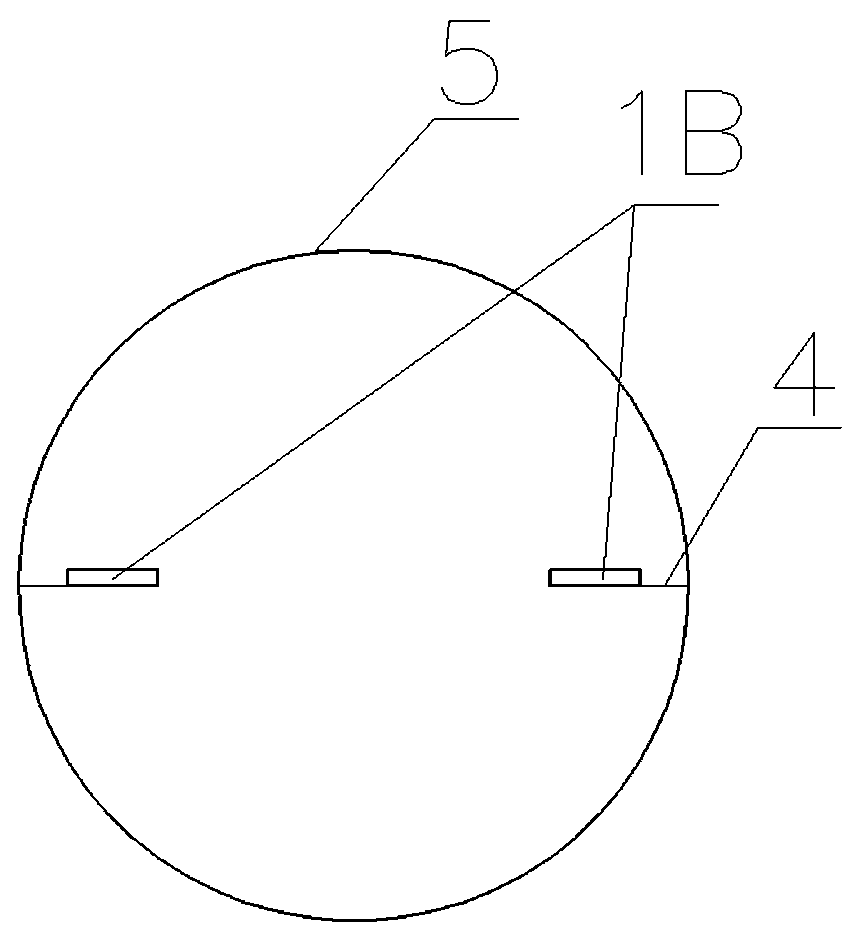

[0022] Numbers in the figure, number 1A stands for plug A, number 1B stands for plug B, number 2 stands for detonator, number 3 stands for blasting chamber, number 4 stands for blasting leg group, number 5 stands for blasting barrel, number 6 stands for water gun mud, number 7 On behalf of the primary explosive volume, the number 8 represents the sacrificial explosive volume, the number 9 represents the layer-by-layer drainage drilling, and the number 10 represents the deep hole pre-splitting drilling.

[0023] In order to make the purpose, technical solution and advantages of the present invention more clear and understandable, the present invention will be further described in detail below in conjunction with the accompanying drawings and technical solutions.

[0024] Coal mine gas drainage enhancement technologies include hydraulic punching, hydraulic fracturing, hydraulic slotting, CO2 blasting fracturing, deep hole pre-splitting blasting, etc., but due to limited use condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com