Two-way valveless microflow pump based on PVDF piezoelectric film and preparation method thereof

A piezoelectric film and micro-flow pump technology, which is applied to pumps, pumps, mechanical equipment, etc. To solve problems such as two-way drive, to achieve the effect of improving product cost performance, solving short service life and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

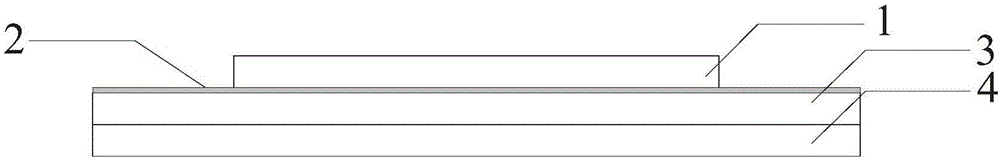

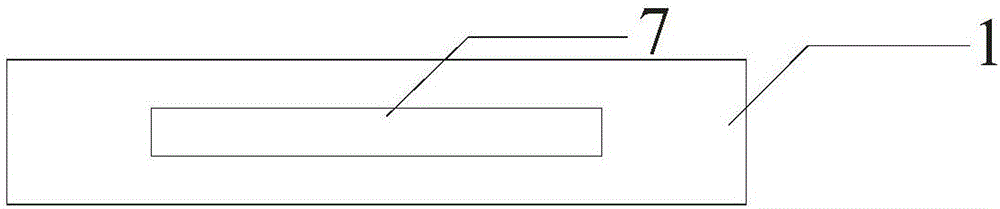

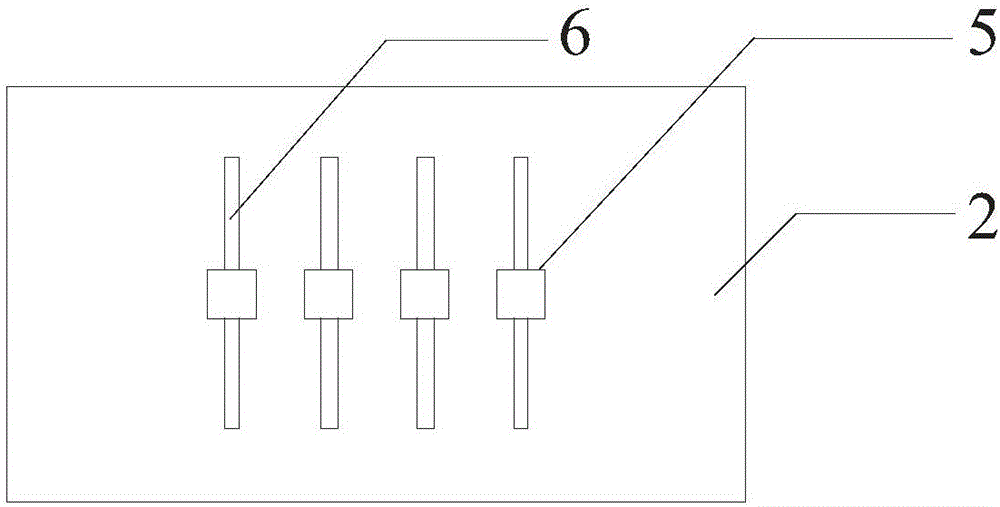

[0027] refer to figure 1 , the two-way valveless microflow pump based on PVDF piezoelectric film of the present invention includes a cover plate 1, a PVDF piezoelectric film 2, a channel layer 3 and a substrate 4 fixedly connected in sequence from top to bottom, wherein the PVDF piezoelectric film The upper surface and the lower surface of 2 are provided with a number of conductive film areas, each conductive film area includes a working area electrode 5 and a conduction area electrode 6 for connecting the working area electrode 5 with an external voltage source, and the PVDF piezoelectric A working area electrode 5 on the upper surface of the film 2 is facing a working area electrode 5 on the lower surface of the PVDF piezoelectric film 2, a through hole 7 is opened on the cover plate 1, and a fluid channel 8 and two fluid channels are opened on the channel layer 3. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com