Lever type rigid large-torque stable transmission continuously variable transmission

A continuously variable transmission and high-torque technology, which is applied to transmission devices, belts/chains/gears, mechanical equipment, etc., can solve the problem of incompatibility between smooth transmission without fluctuations and rigid high-torque transmission, and achieve the effect of uniform output rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

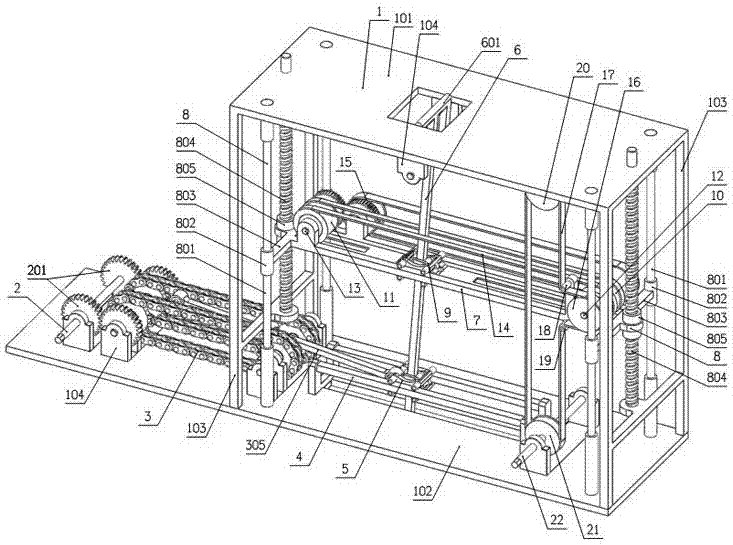

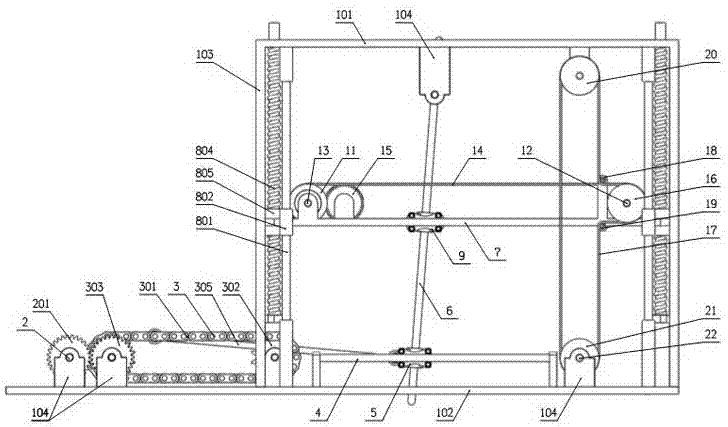

[0058] A lever-type rigid high-torque stable transmission continuously variable transmission, the continuously variable transmission of this embodiment is a structure with connecting rods, and its specific structure is as follows figure 1 , figure 2 As shown, the continuously variable transmission includes a fixed frame 1 and a power input unit, a speed change unit and a power output unit all arranged on the fixed frame 1. The power input unit, the speed change unit and the power output unit are all in one group. The structure refers to the above settings. In this continuously variable transmission, the power input shaft 2 and the parallel chain mechanism 3 are arranged on the extended platform outside the bottom plate 102 of the fixed frame 1, and the parallel chain mechanism 3 is installed on the main push block 5 on the fixed track 4 through the connecting rod 305 and sliding connect.

Embodiment 2

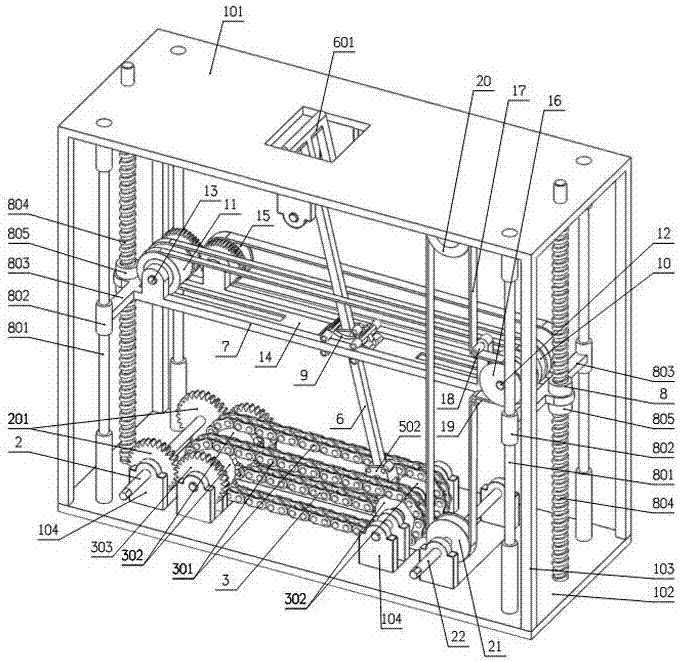

[0060] A lever-type rigid high-torque stable transmission continuously variable transmission. This embodiment uses a non-link structure to reduce the volume of the transmission. The specific structure is as follows image 3 , Figure 4 As shown, the continuously variable transmission includes a fixed frame 1 and a power input unit, a speed change unit and a power output unit all arranged on the fixed frame 1. The power input unit, the speed change unit and the power output unit are all in one group. The structure refers to the above settings. In this continuously variable transmission, the extended platform on the outside of the fixed frame bottom plate 102 and the fixed track 4 on the fixed frame bottom plate 102 are cancelled, and the power input shaft 2 and the parallel chain mechanism 3 are arranged on the bottom plate 102 of the fixed frame 1 for direct use. The main core body 502 of the main push block 5 replaces the long pin shaft 304 in the parallel chain mechanism 3 ...

Embodiment 3

[0062] A lever-type rigid high-torque stable transmission continuously variable transmission, this embodiment is the parallel form of two groups of embodiment 2, and its specific structure is as follows Figure 5 , Figure 6 shown. In the case of two groups of parallel connections, the power input unit and the speed change unit are two groups, and the two groups of speed change units share a set of track lifting guide device 8, and the two right central shafts 12 can be combined into one right central shaft, Two left central shafts 13 can be combined into one left central shaft. Correspondingly, only one set of two sets of rotation integration devices 15 may be reserved, and only one set of two sets of power output units may be reserved. In this embodiment, in order to output continuous and smooth rotation without fluctuations, it is necessary to connect parallel chains. Stagger 1 / 4 chain length.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com