Car gear shifter

A technology for shifting gears and moving baffles in automobiles, which is applied to components with teeth, transmission control, belts/chains/gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

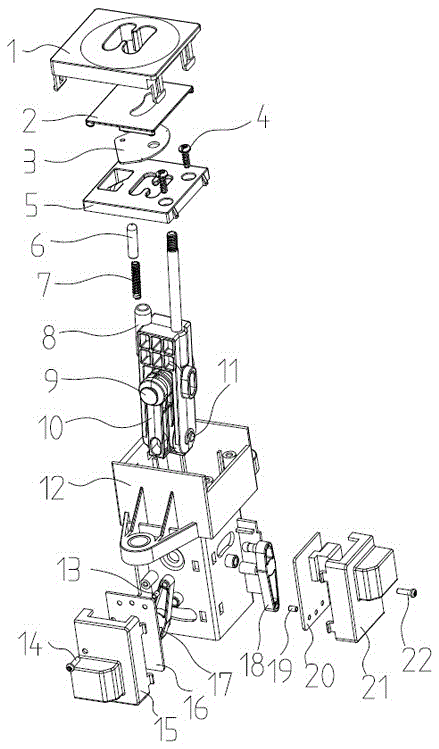

[0017] Below in conjunction with accompanying drawing, this kind of automobile shifter is further described:

[0018] Such as figure 1 As shown, the shifter includes an upper cover 1, a movable baffle 2, a fan-shaped baffle 3, a fixing screw 4, a cover plate 5, a metal post 6, a spring 7, a large swing arm 8, a large fixed pin 9, and a small swing arm 10 , small fixing pin 11, housing 12, permanent magnet 13, fixing screw 14, circuit board cover 15, circuit board 16, swing lever 17, swing lever 18, permanent magnet 19, circuit board 20, circuit board cover 21, fixing screw twenty two.

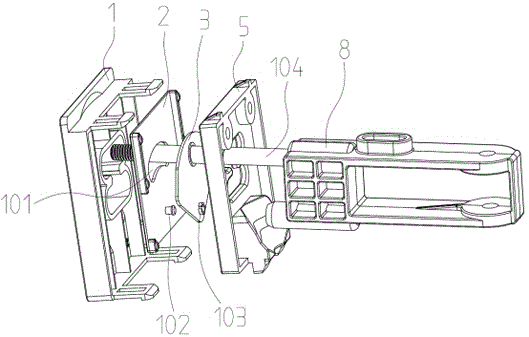

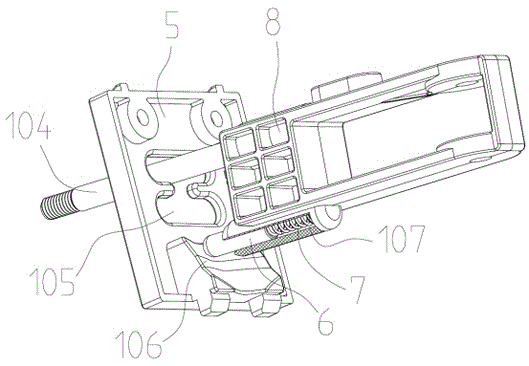

[0019] Such as Figure 2~Figure 7 As shown, the large swing arm 8 and the small swing arm 10 are hinged by the small fixed pin 11, and the large swing arm 8 can swing around the small fixed pin 11. The small swing arm 10 hinges the large swing arm 8 and the small swing arm 10 on the housing 12 through the large fixed pin 9, and the large swing arm 8 and the small swing arm 10 can swing aroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com