Intelligent on-line checking method for transformer oil surface thermometer

A calibration method and technology for thermometers, applied in thermometer testing/calibration, thermometers, instruments, etc., can solve problems such as increased operation and maintenance workload, power outage of power transformers, and labor consumption, so as to improve maintenance coordination efficiency and ensure safety and stability. running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

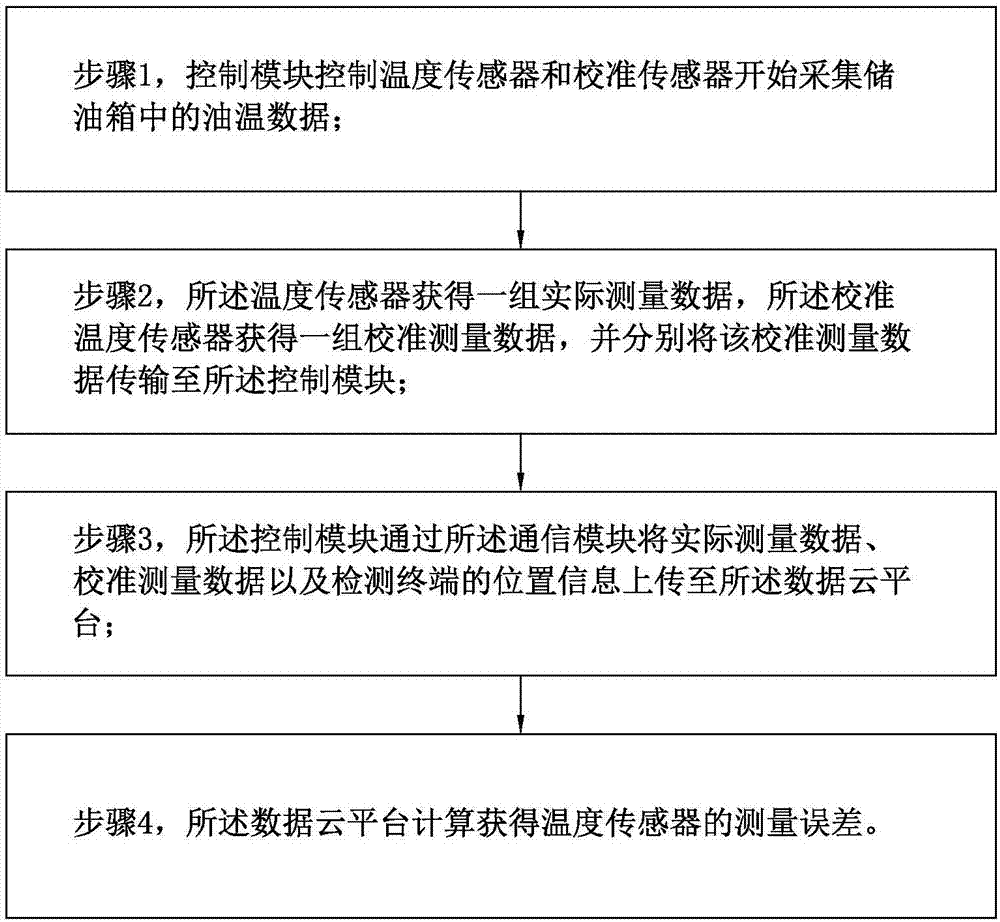

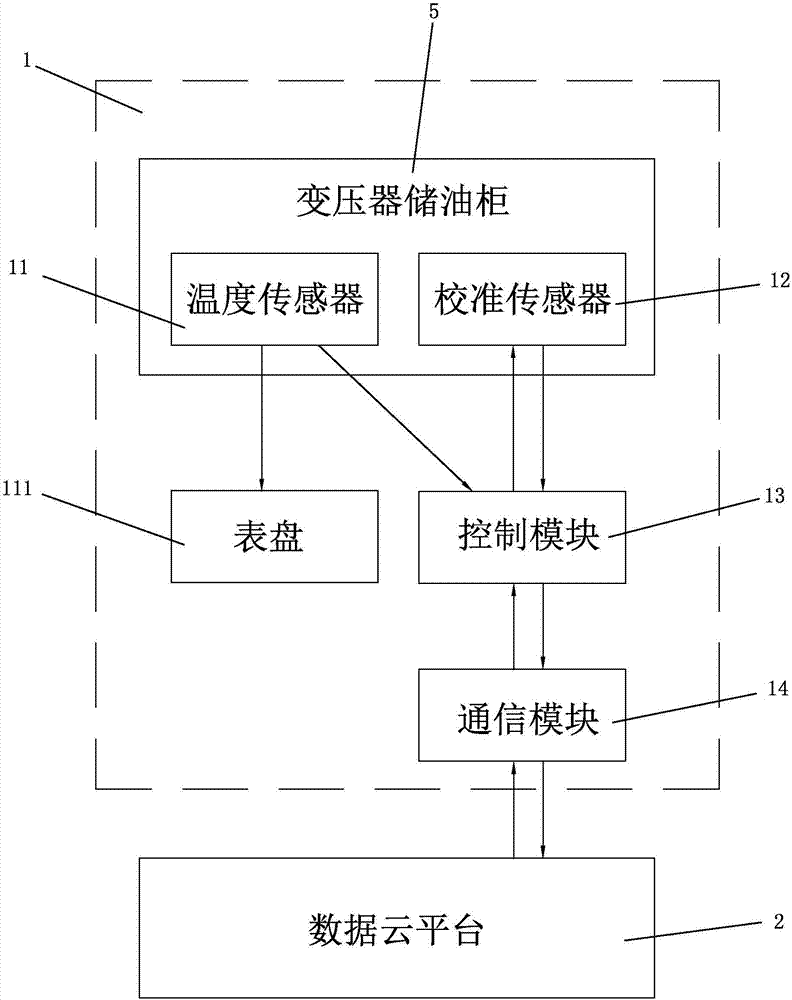

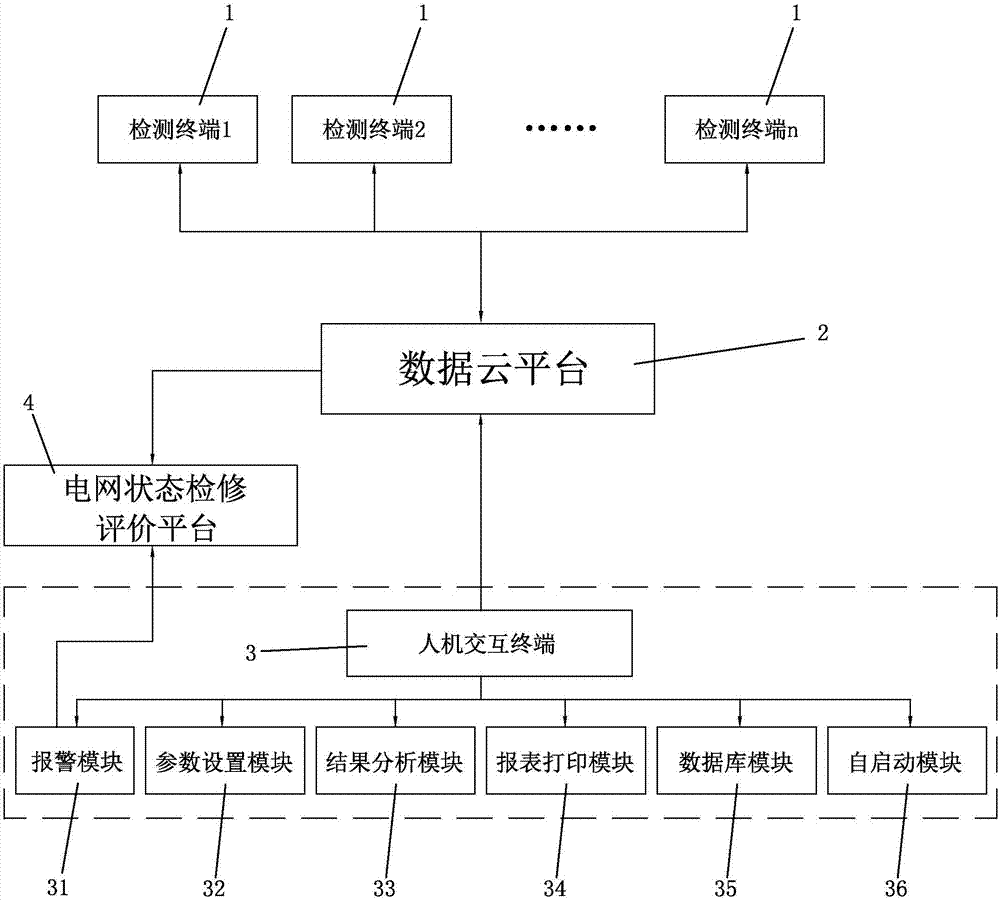

[0027] see Figure 1 to Figure 3 As shown in the figure, an intelligent online calibration method for a transformer oil surface thermometer of the present invention, the transformer is provided with an oil surface thermometer, the oil surface thermometer includes a dial 111 and a temperature sensor 11, and the temperature sensor 11 of the oil surface thermometer is immersed in the In the oil storage tank 5 of the transformer; an intelligent calibration terminal 1 is set on the transformer, and the intelligent calibration terminal 1 includes a calibration sensor 12, a control module 13 and a communication module 14, and the control module 13 is respectively connected with the oil surface thermometer. The temperature sensor 11 and the calibration sensor 12 are signally connected, and the control module 13 is signally connected to the communication module 14; the detection accuracy of the calibration sensor 12 is higher than that of the temperature sensor 11 of the oil surface the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com