Manufacturing method of array substrate and manufacturing method of display device

A manufacturing method and array substrate technology, which are applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve problems such as increased production costs, threshold voltage drift, and long production cycles of flexible OLEDs. Effects of production cycle, reduction of production cost, and avoidance of threshold voltage drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order for those skilled in the art to better understand the technical solution of the present invention, the method for manufacturing the array substrate and the method for manufacturing the display device provided by the present invention will be described in detail below with reference to the accompanying drawings.

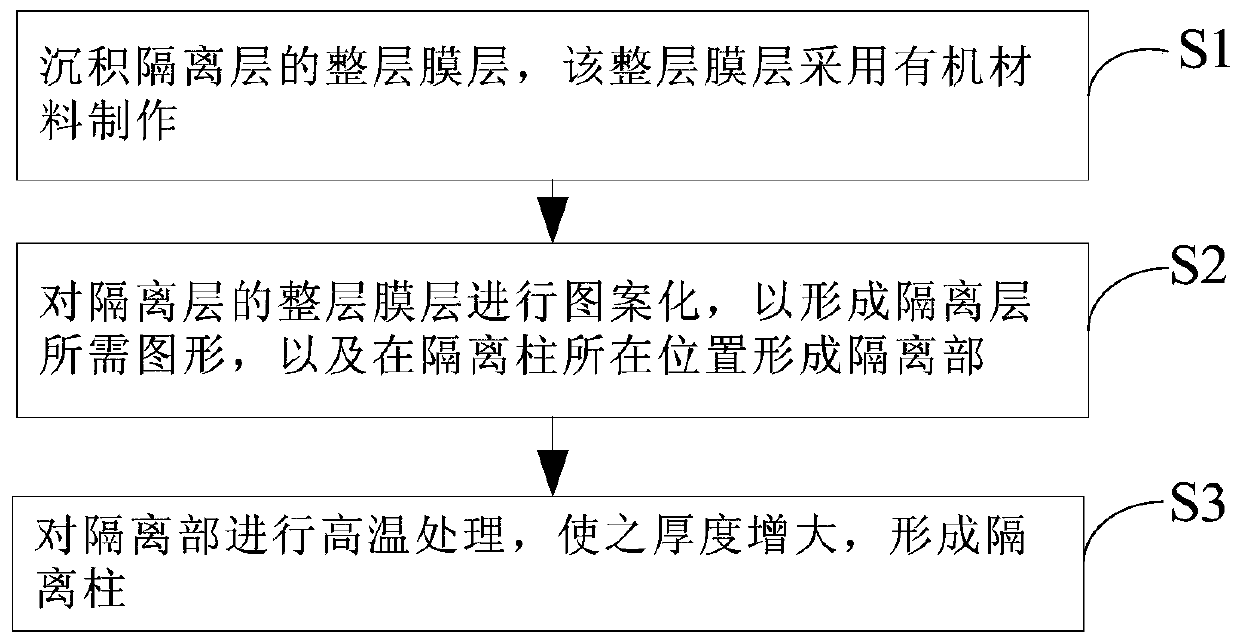

[0039] figure 1 It is a block flow diagram of the manufacturing method of the array substrate provided by the first embodiment of the present invention. see figure 1 , the manufacturing method of the array substrate includes:

[0040] Making the isolation column while making the isolation layer specifically includes the following steps:

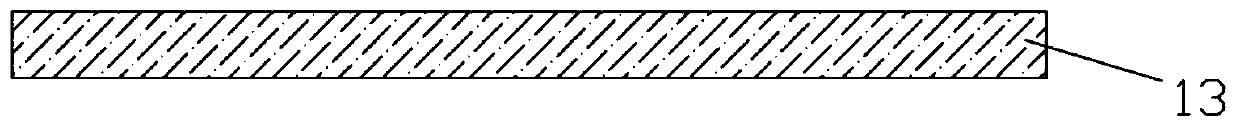

[0041] S1, forming the film 13 of the isolation layer, the film 13 of the isolation layer is made of organic materials, such as Figure 2A shown.

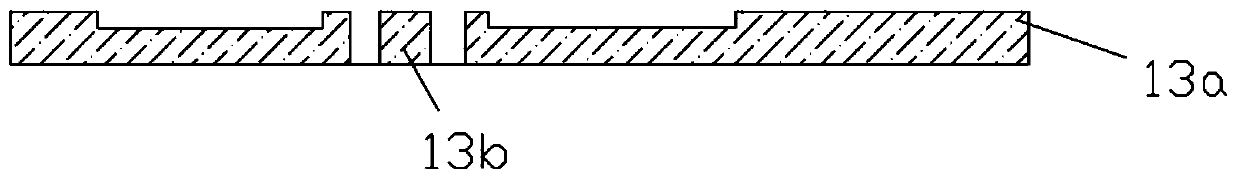

[0042] S2, patterning the thin film 13 of the isolation layer to form the required pattern 13a and isolation portion 13b of the isolation layer, such as Figure 2B sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com