Full-automatic battery pack blocking and press fitting structure

A press-fit structure and battery pack technology, applied in structural parts, assembled battery machines, secondary battery manufacturing, etc., can solve problems such as low compatibility, high manufacturing cost, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

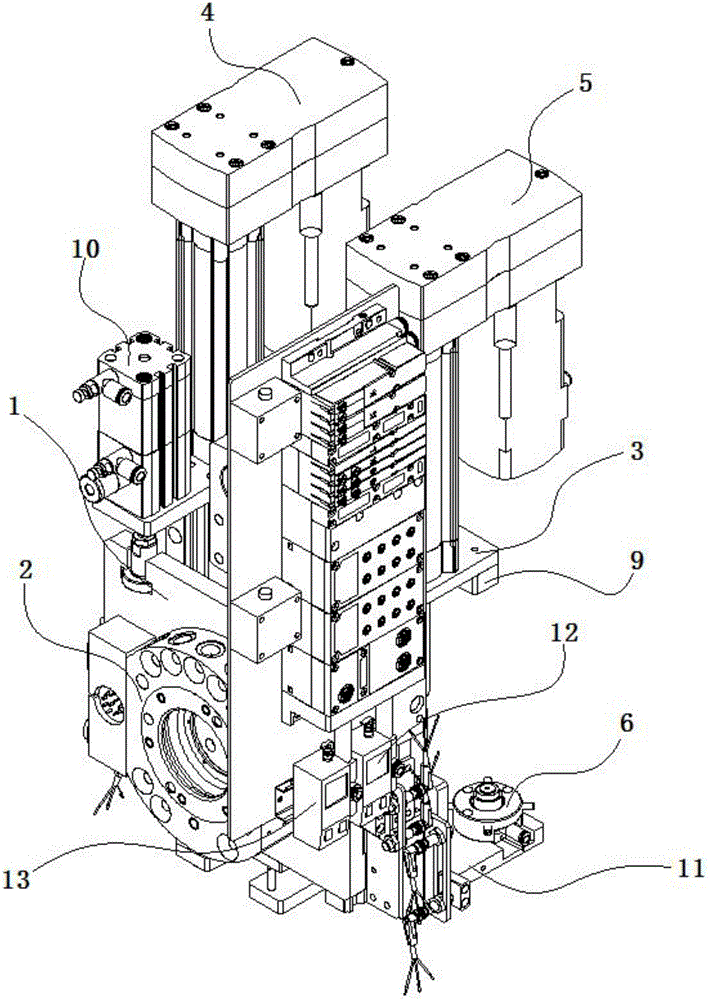

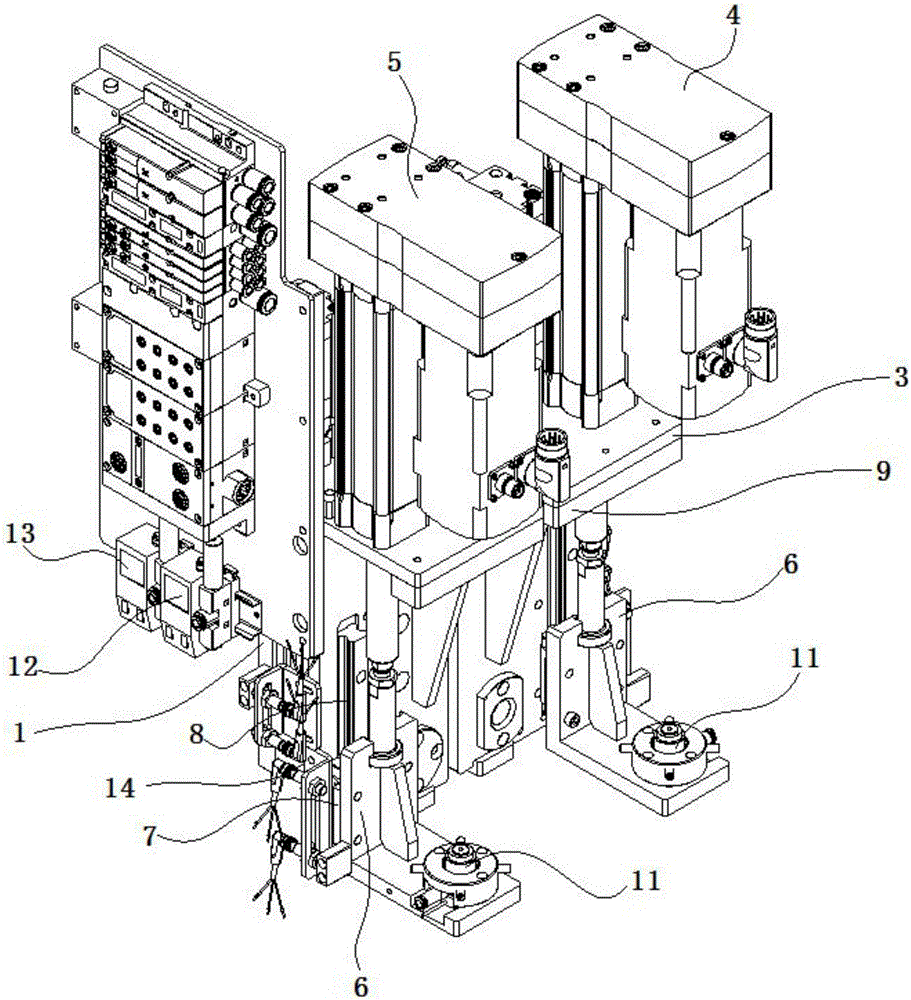

[0027] see figure 1 , figure 2 , a fully automatic battery pack plugging and pressing structure provided by the embodiment of the present invention, such as figure 1 , figure 2 As shown, the structure includes a main frame 1, and the main frame 1 is used to carry various components;

[0028] The robot quick-change female head 2, the robot quick-change female head 2 is fixedly installed on one side of the main frame; the robot quick-change female head 2 can be used for docking and tightening by a six-axis robot, and the structure is moved by a six-axis robot to the designated workstation.

[0029] A plugging press-fitting assembly, which is installed on the main frame 1 on the side opposite to the fixed side of the robot quick-change female head 2; Plate 3, the upper part of the fixed plate 3 is symmetrically arranged and connected with the first servo electric cylinder 4 and the second servo electric cylinder 5, and the respective lead screws of the first servo electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com