Fertilizer discharging device of fertilizer applicator

The technology of a fertilization device and a fertilizer applicator is applied in the directions of fertilization device, fertilizer distributor, application, etc., which can solve the problems of small fertilization amount, time-consuming and laborious, and insufficient power of the fertilization device, so as to improve the fertilization efficiency and the fertilization quality. , the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

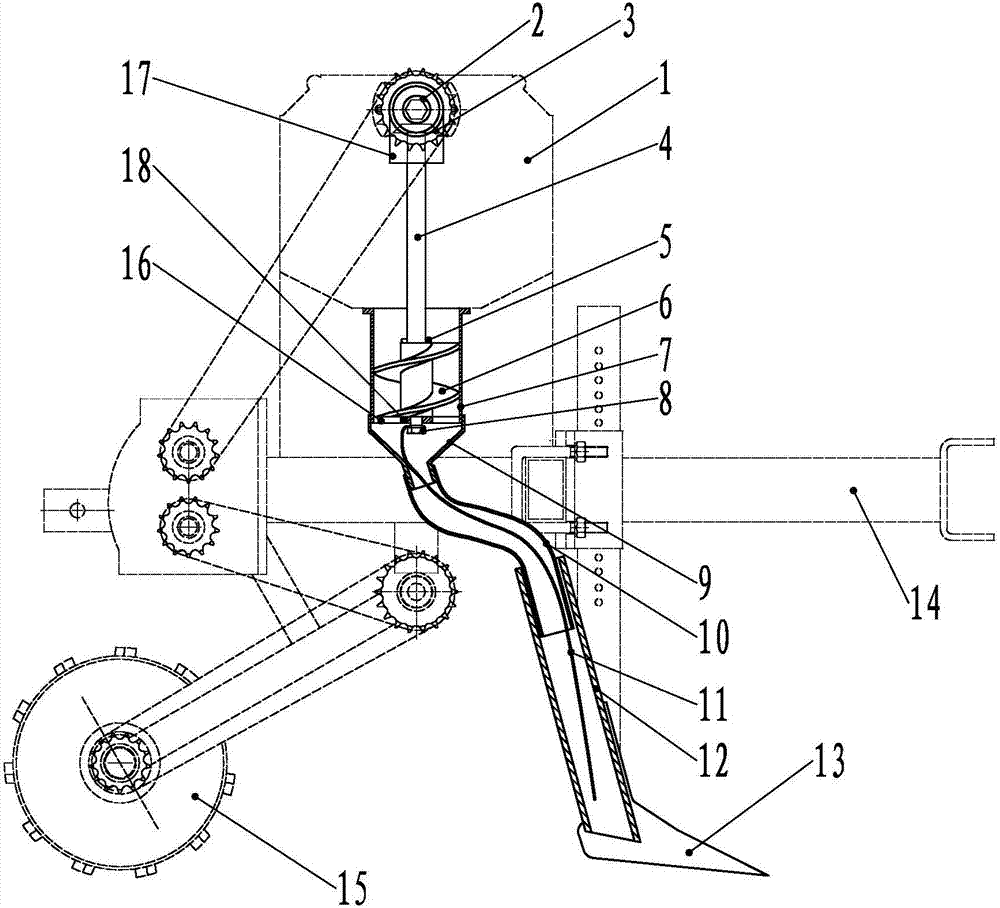

[0012] Below in conjunction with accompanying drawing and specific embodiment the fertilizer discharge device of fertilizer applicator of the present invention is further described:

[0013] Accompanying drawing is the structural representation of the fertilizer discharge device of the fertilizer applicator of the present invention. Among the figure, the frame connecting rod 14 of the fertilizer applicator can be connected with agricultural machinery such as tractors, the top of the frame connecting rod 14 is provided with a fertilizer box 1, and the following of the frame connecting rod 14 is provided with a plowshare 13 and a walking wheel 15, and the walking wheel 15 It is arranged behind the plowshare 13, and a drive shaft 2 is set above the fertilizer box 1. The drive shaft 2 is provided with a reverse gear box 17. The fertilizer discharge box 7 is fixed on the bottom surface of the fertilizer box 1, and an auger is arranged in the fertilizer discharge box 7. 6. The botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com