Rotary aerator

A kind of aeration machine, rotary technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of wave making, uneven stirring of water, low efficiency, etc., and achieve the effect of high oxygenation efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

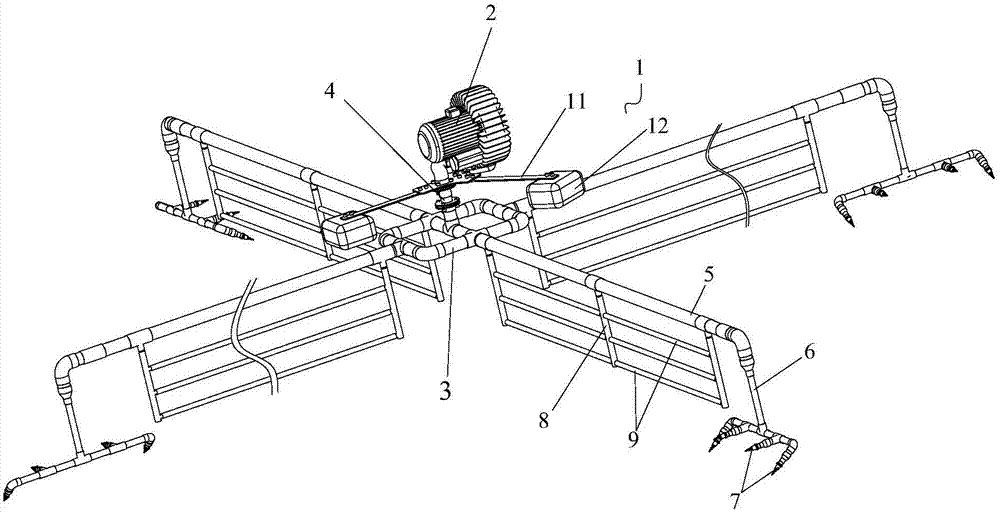

[0014] Such as figure 1 As shown, the present invention includes a floating frame 1 and an air pump 2. The floating frame 1 includes a supporting frame 11 and a floating body 12 fixed around the supporting frame 11. The air pump 2 is fixed on the floating frame 1. The air outlet of the air pump 2 is connected with an air outlet pipe 21. The aerator also includes an air distribution pipe 3. The air inlet end of the air distribution pipe 3 is connected to the air outlet pipe 21 through a rotary joint 4. Two or more air supply main pipes 5 are connected to the annular part at intervals along the circumferential direction. The free end of the air supply main pipe 5 is connected with an air supply branch pipe 6 extending downward, and the bottom of the air supply branch pipe 6 is connected with a spray head 7. 7 Jet airflow in the same direction of rotation; the bottom of the air supply main pipe 5 is provided with at least two downwardly extending air branch pipes 8 at intervals al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com