Rotary cutter for acetabulum

A rotary knife and acetabular technology, applied in the field of acetabular rotary knife, can solve the problems of high manufacturing cost, short tool life, complex structure, etc., and achieve the effect of low manufacturing cost, extended service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

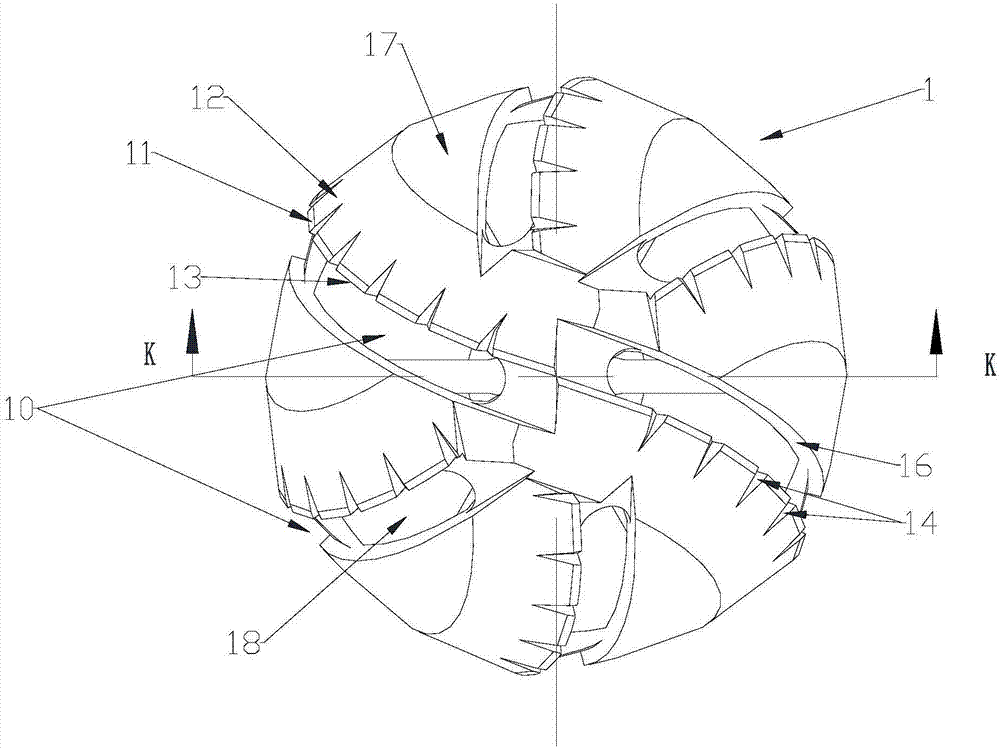

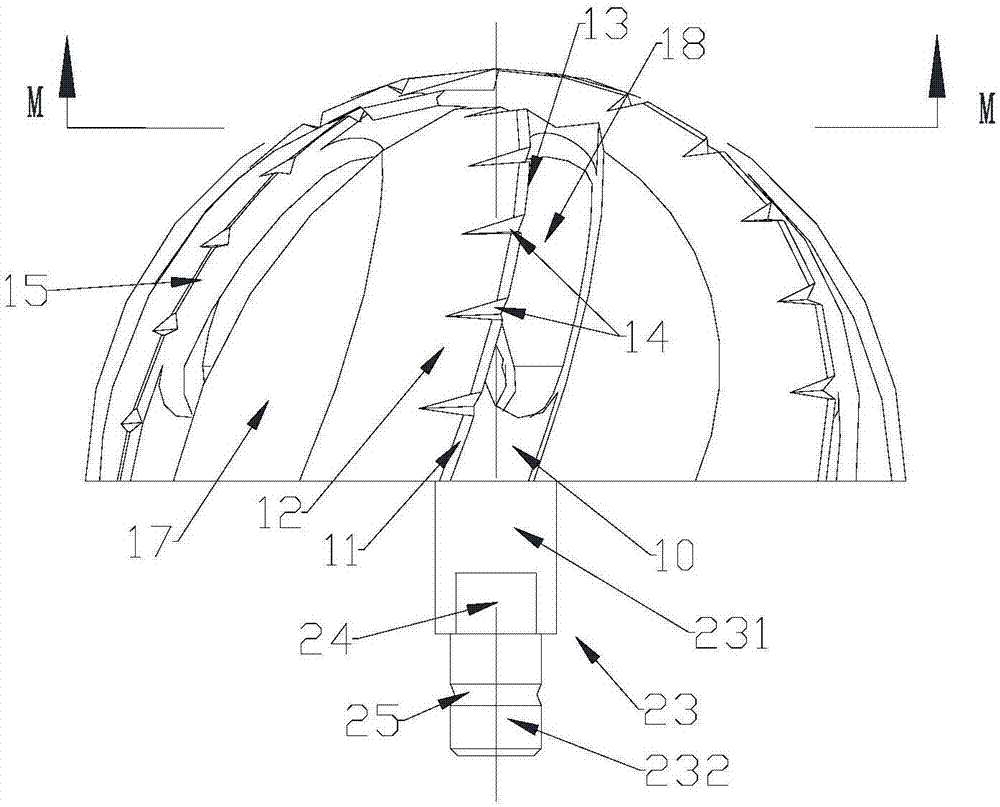

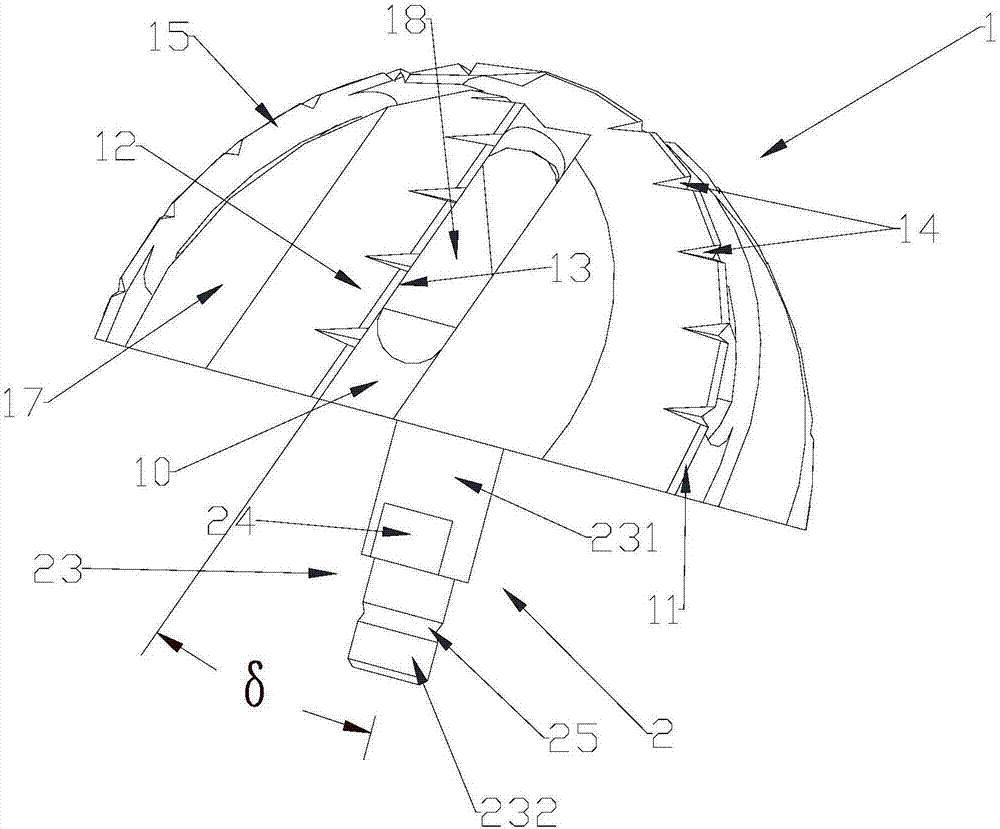

[0034] Such as figure 1 As shown, the acetabular rotary knife includes a hemispherical shell 1 and a bracket 2. The acetabular rotary knife of the present invention greatly prolongs the service life of the acetabular rotary knife by optimizing the parameters of the cutting edge 13. In addition, the acetabular rotary knife of the present invention The knife also has the advantages of simple structure and low manufacturing cost.

[0035] Such as figure 2 , 3, 6, 7, 9, and 10, the hemispherical shell 1 is a hemispherical shell 1 with a cavity 19 inside the lower port, and the connection between the apex of the hemispherical shell 1 sphere and the center of the hemispherical shell 1 The line is the axis of rotation, and the hemispherical shell 1 rotates around the axis of rotation when it rotates. Three pairs of grooves 10 are evenly arranged around the vertex on the spherical surface, and of course four pairs, five pairs or more grooves 10 can be arranged as required, and the...

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 is that in this embodiment, the rake angle α is constant during the process of extending downward along the rear side 15 of the groove 10, and the value range of the rake angle α is 3°-45°. °, the first relief angle β also remains constant during the downward extension, and the value range of the first relief angle β is 6°-12°. The second relief angle γ is also constant during the downward extension, and the value range of the second relief angle γ is 15°-25°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com