Ore grinding and sieving device

A screening device and ore crushing technology, which is applied in the direction of screening, solid separation, and separation of solids from solids with airflow, can solve the problems of low and high sorting efficiency, and achieve high sorting efficiency, It is convenient for vibration screening and improves the effect of vibration separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

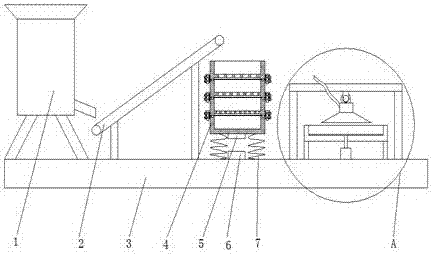

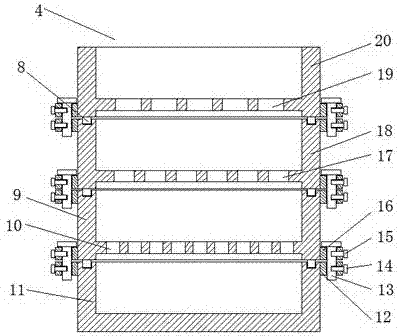

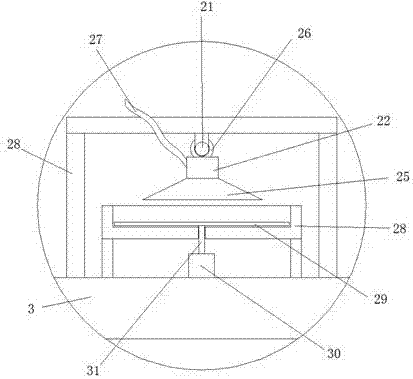

[0029] see Figure 1-4 , an ore crushing and screening device, comprising a bottom plate 3, on which an ore pulverizer 1 and a conveyor belt 2 are fixedly supported, on the bottom plate 3, a particle size separation device 4 is supported by a spring 7, and the number of the springs 7 is two , and it is evenly distributed on both sides of the electromagnet 6, and the vibration separation effect is improved by two springs 7. The left end of the conveyor belt 2 is located under the outlet bucket of the ore pulverizer 1, and an iron block is fixedly connected to the lower side of the particle size separation device 4. 5. The bottom plate 3 is connected with an electromagnet 6, and the electromagnet 6 is located below the iron block 5, and the right end of the conveyor belt 2 is located above the feed port of the particle size sorting device 4, and the particle size sorting device 4 includes the first sorting barrel 20. The second sorting barrel 18, the third sorting barrel 9 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com