Automatic unqualified product removing mechanism of rotating disk type assembling machine

An assembly machine, turntable technology, applied in sorting, other medical devices, drug devices, etc., can solve the problems of missed inspection or wrong judgment by inspectors, small size of syringes, damage to the reputation of users and enterprises, etc. Accuracy and efficiency, uniform distribution of silicone oil, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

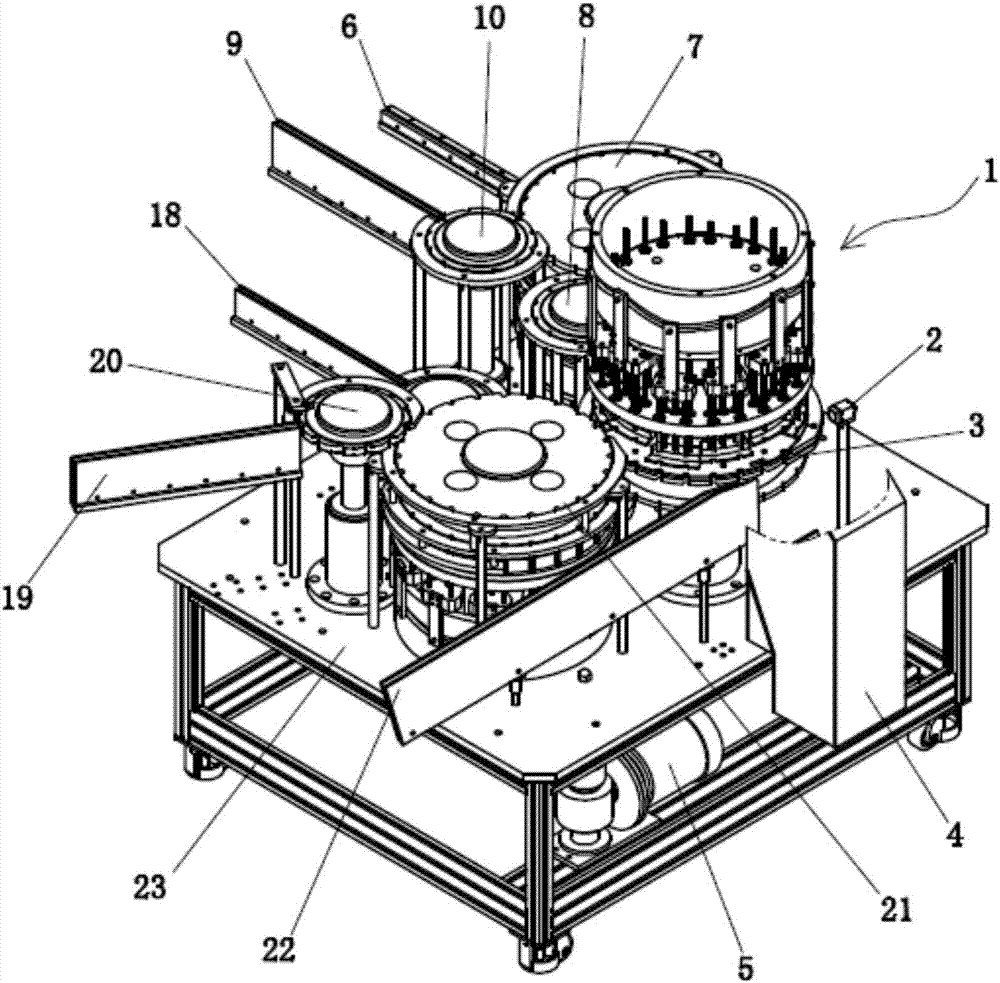

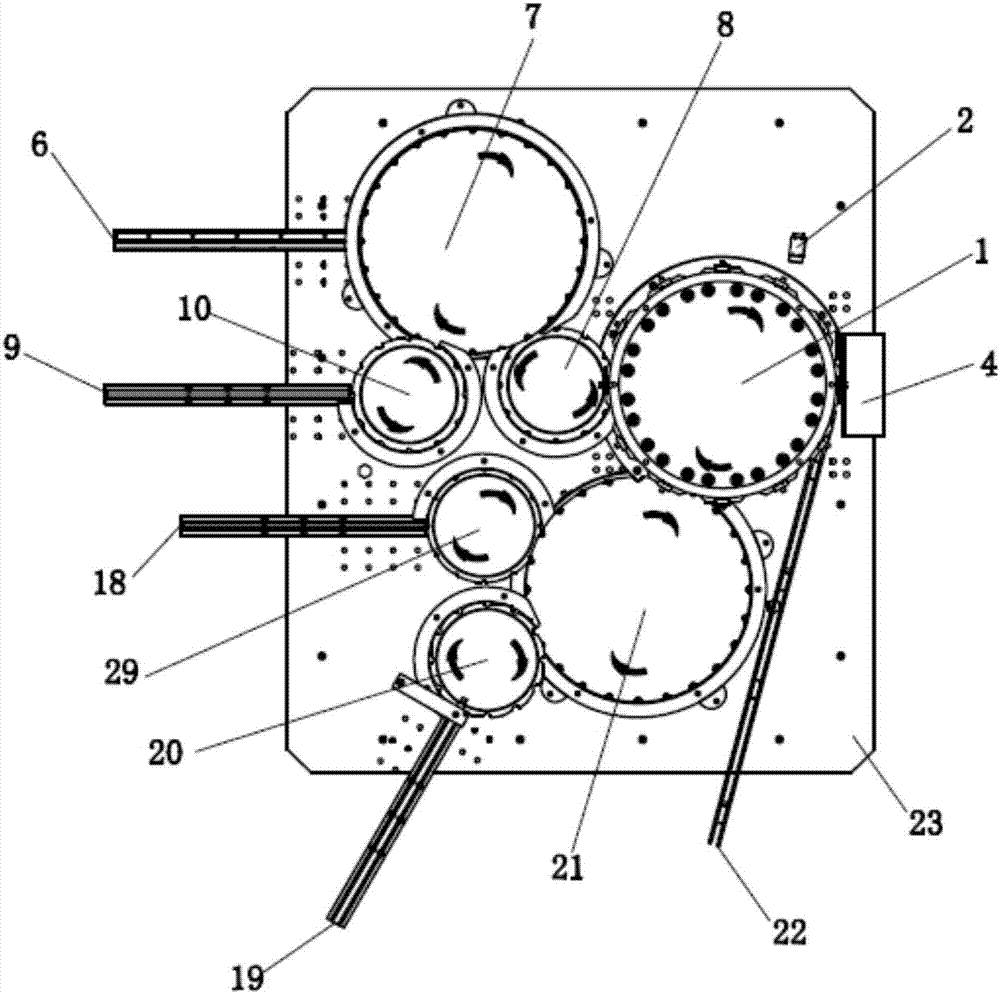

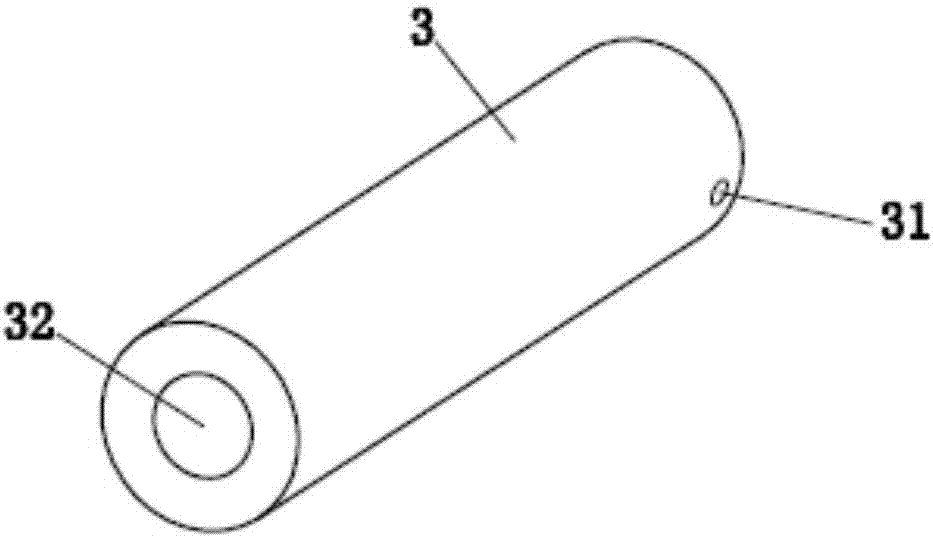

[0038] The specific embodiment of the present invention is as Figure 1 to Figure 8 As shown in the figure, a mechanism for automatically removing defective products of a turntable assembly machine includes a machine table 23 and a first drive mechanism 5 connected with a device for assembling the syringe combination and the push rod combination into finished syringes. The first assembly device 1, one side of the first assembly device 1 is provided with a finished product output channel 22, it is characterized in that, between the first assembly device 1 and the finished product output channel 22, an image comparison device 2 capable of photographing the finished product is provided Connected with the image comparison device 2 and the defective syringe removal device 3 , the rejected defective syringes fall into the defective removal channel 4 on the machine platform 23 . The first assembly device 1 includes a plurality of moving mechanisms 14 capable of moving the push rod as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com