Automatic cutting conveyor of deepwater aquatic plants for environmental water treatment

An automatic cutting and conveyor technology, which is applied to harvesters, cleaning of open water surfaces, and motor vehicles, etc., can solve problems such as inability to cut, threats to tourists' lives, and hazards to tourists.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

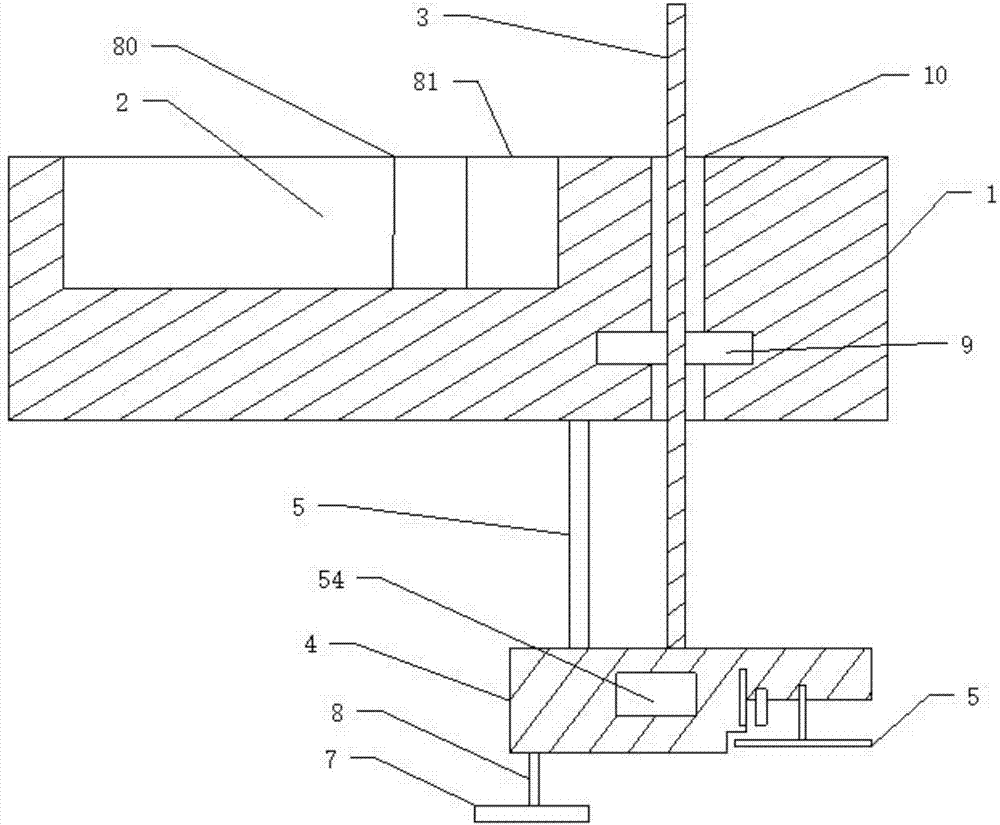

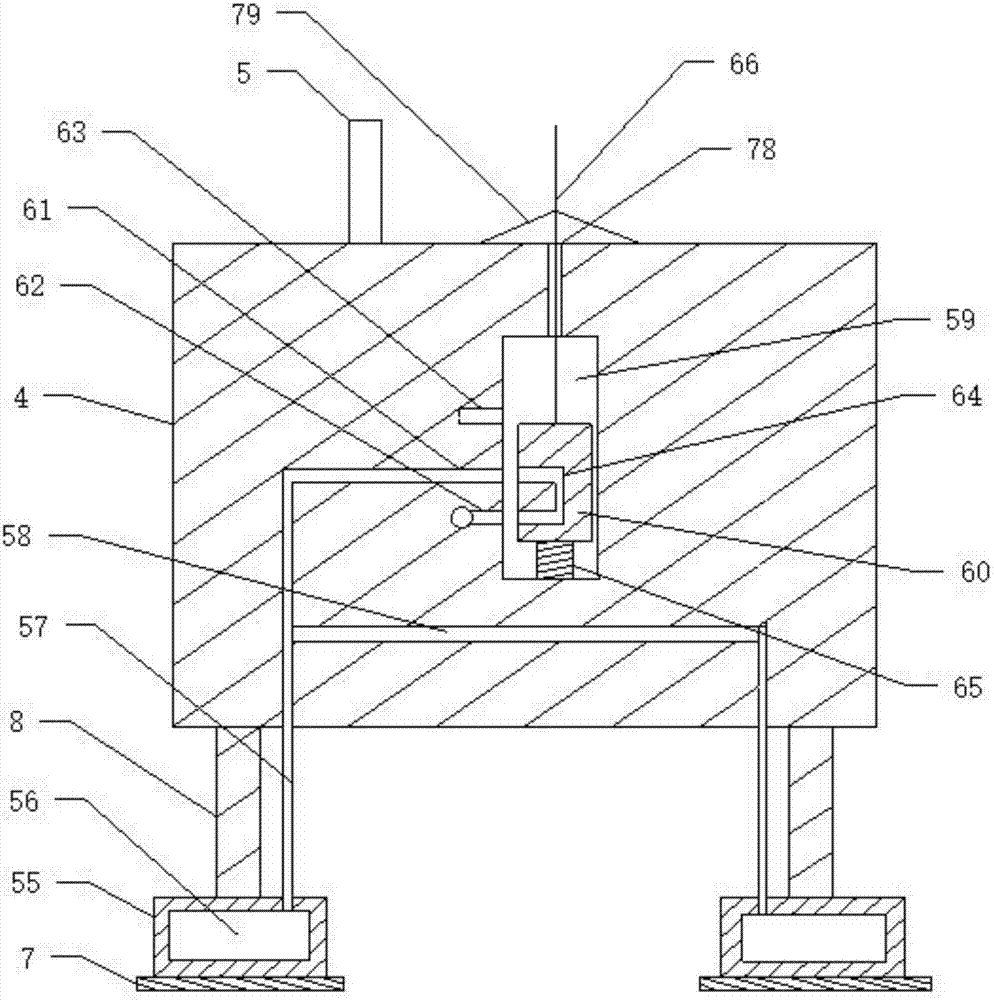

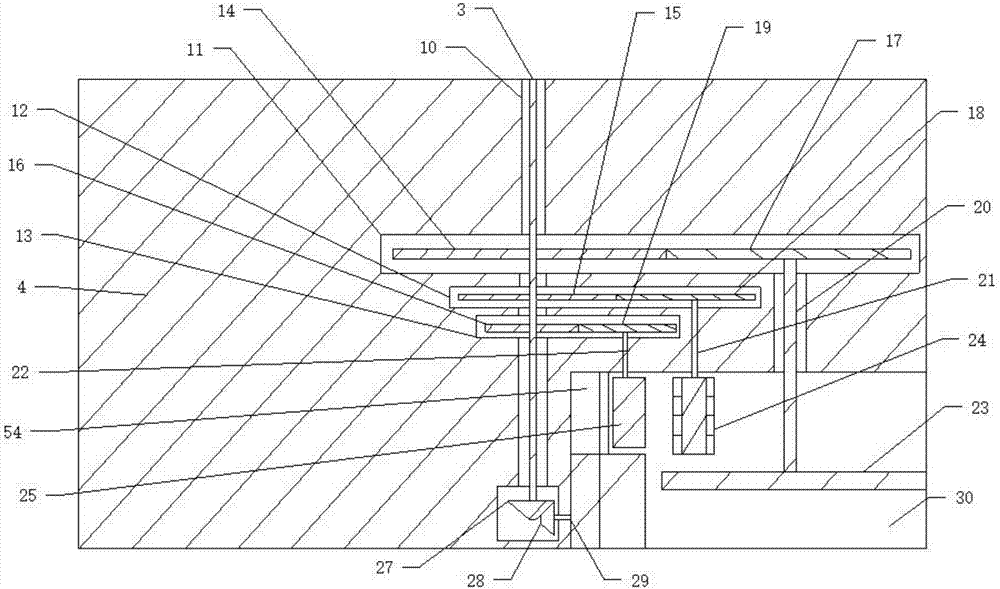

[0038] Such as Figure 1 to Figure 13 As shown, an automatic cutting conveyor for deep-water aquatic plants for environmental water treatment includes a hull 1, a cabin 2 is provided on the hull 1, and a cutting conveyor 4 is provided on the hull 1. A sliding driving rod 3 is provided on the hull 1 , the driving rod 3 rotates in the cutting conveyor 4, the cutting conveyor 4 is provided with a cutting groove 30, the cutting groove 30 is provided with a rotating cutting turntable 23, the cutting turntable 23 There is a cutting platen 33 that swings in a circle on the top, and a pressing slide bar 35 corresponding to the cutting platen 33 is provided in the cutting groove 30, and the pressing slide bar 35 presses the cutting plate. Platen 33. A rotating driving rod 3 is arranged on the hull 1, the driving rod 3 can slide on the hull 1, and the driving rod 3 can slide on the bottom of the hull 1, and can further extend into the lake It can continue to rotate later on, and a cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com