Telescopic belt type weight-volume measuring and code-scanning intelligent all-in-one machine

A weight-volume, belt-type technology, applied in conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

[0021] A kind of embodiment of the present invention is provided below:

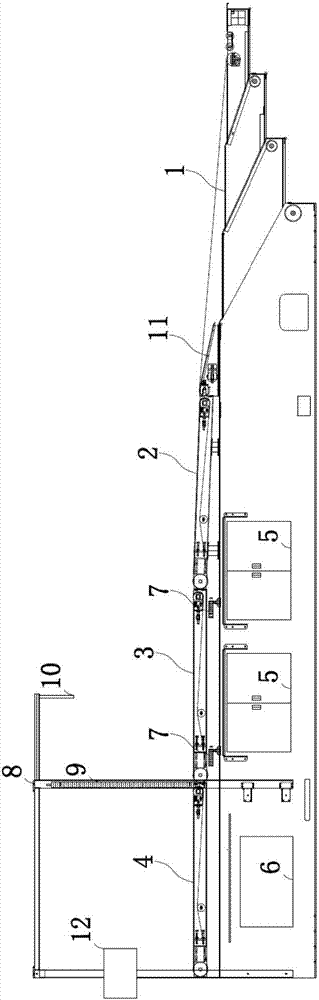

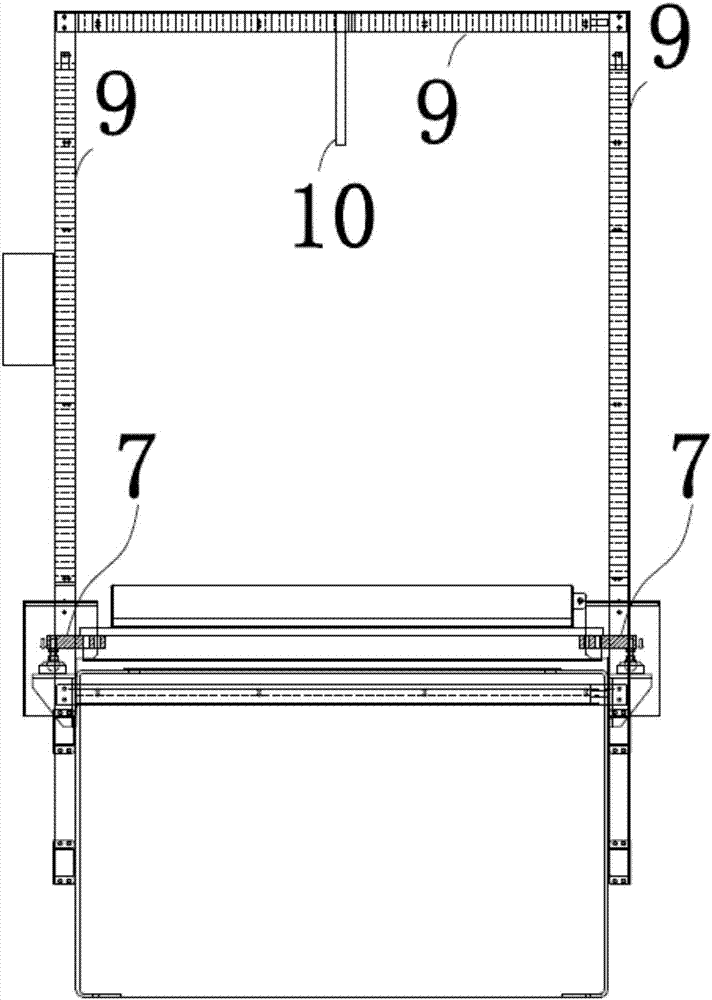

[0022] See Figures 1 to 2 , a telescopic belt-type weight and volume measurement intelligent all-in-one machine for scanning codes, comprising a telescopic belt conveyor 1, on one side of the telescopic belt conveyor 1, a dragging section conveyor belt 2, a weighing section conveyor belt 3, a fast Detachment section conveyor belt 4, the tow speed section conveyor belt 2, the weighing section conveyor belt 3, and the fast detachment section conveyor belt 4 rotate under the drive of the roller;

[0023] It also includes a weighi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com