Wall-mounted furniture production device

A production device and wall-mounted technology, which is applied in the field of wall-mounted furniture production devices, can solve the problem that rubber and plastic strips cannot be automatically rolled up, and achieve the effects of saving space utilization, high degree of automation, and high work continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

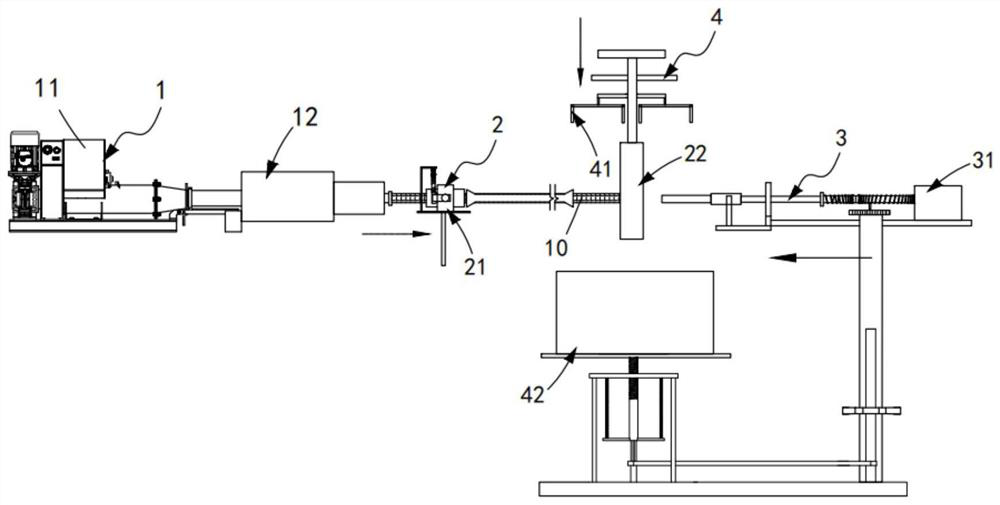

[0071] Such as figure 1 As shown, a wall-mounted furniture production device includes:

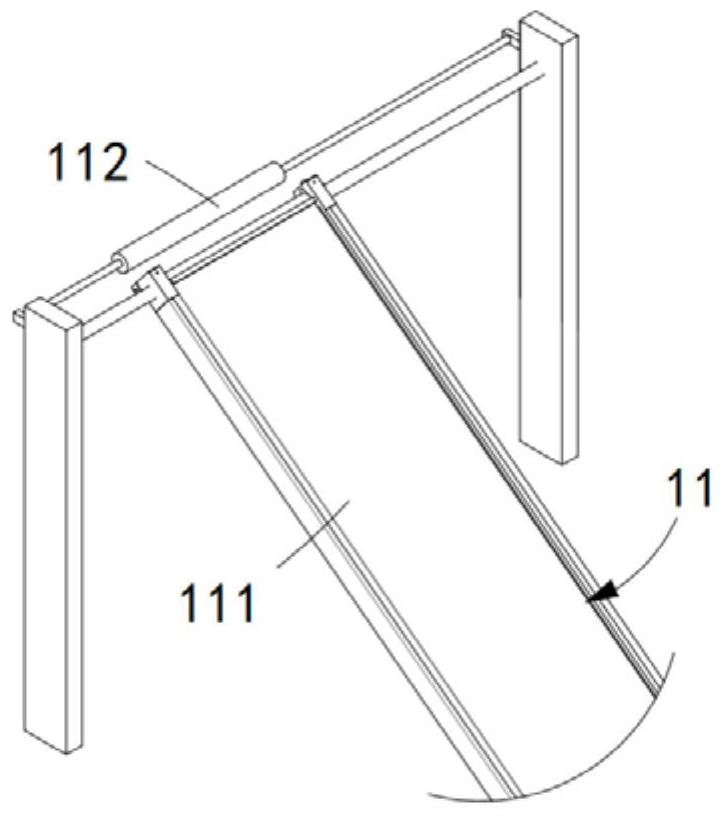

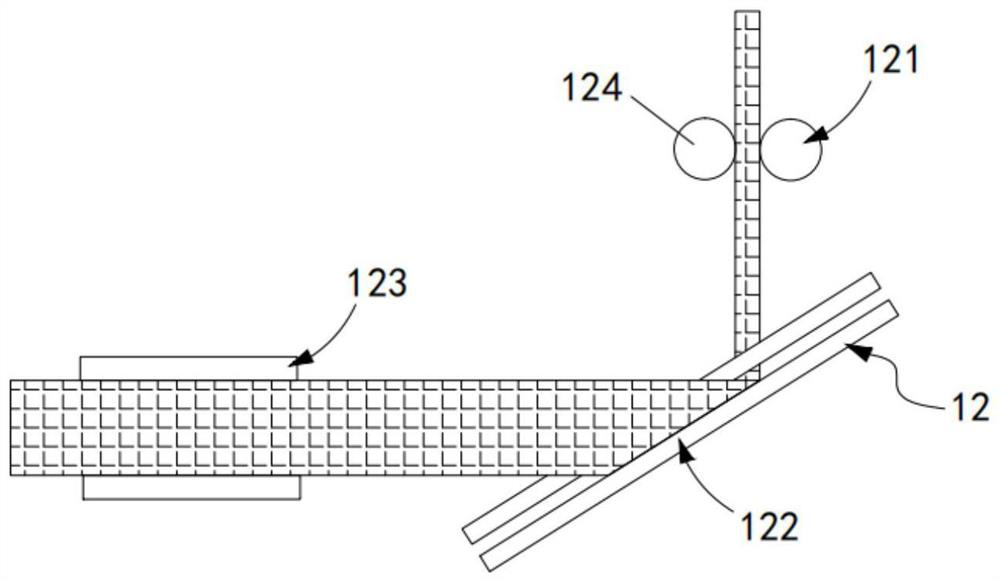

[0072] A transmission mechanism 1, the transmission mechanism 1 comprising a transmission assembly 11 and a guide assembly 12 arranged below the transmission assembly 11;

[0073] The traction mechanism 2, the traction mechanism 2 includes a clamping assembly 21 arranged at the output end of the guide assembly 12 and a support assembly 22 arranged on one side of the clamping assembly 21 and matched with the clamping assembly 21;

[0074] The winding mechanism 3, the winding mechanism 3 includes a hoop assembly 31 arranged on one side of the support assembly 22 and a cutting assembly synchronously driven with the hoop assembly 31 and used for cutting the rubber strip 10 32, a clamping mold 33 is placed on the hoop assembly 31; and

[0075] Stacking mechanism 4, described stacking mechanism 4 comprises the push-down assembly 41 that is arranged on described support assembly 22 top and the ...

Embodiment 2

[0122] Such as Figure 20 to Figure 21 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0123] further, such as Figure 20 to Figure 21 As shown, the clamping mold 33 includes two sets of fixed assemblies 331 arranged symmetrically, one end of the two sets of fixed assemblies 331 is hingedly connected, and the fixed assemblies 331 include a first clamping member 332;

[0124] The first clamping member 332 includes a hoop 3321 with a semicircular structure, a bump d3322 arranged on the outer wall of the hoop 3321 and matched with the outer wall of the bump c3169, and a bump d3322 arranged on the outer wall of the hoop 3321. The clamping rod 3323 arranged on one side and perpendicular to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com