Novel rubber composition for automobile water pipe, preparation method and product thereof

A technology of rubber composition and rubber products, applied in the field of artificial rubber, which can solve the problems of appearance blooming, energy, economic benefit and production efficiency loss, and achieve the effects of low cost, good vulcanizate performance and stable shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] The technical solutions of the present invention will be further described below in conjunction with specific examples.

[0037] Table 1 The raw material components and their proportions of the sulfur vulcanized EPDM composition of Examples 1-5

[0038] Raw material composition (unit: g) Example 1 Example 2 Example 3 Example 4 Example 5 First EPDM 20 30 40 70 70 Second EPDM 80 70 60 30 30 Zinc oxide 5 5 5 5 5 stearic acid 1 1 1 2 2 sulfur 0.5 0.5 0.5 1 0.5 Vulcanizing agent TETD 1 0 0 0 0 Accelerator TBzTD-70 1 1.5 1.5 1 1.5 DPTT 0 1 1 1 1 Accelerator CZ 1 1 1 1 1 DTDM 0 0 1.5 0 1.5 DTDC-80 1.5 1.5 0 0 0 Accelerator BZ 1 1.5 1.5 1.5 1.5 Auxiliary cross-linking agent TAIC 1 1 1 1 1 Antiaging agent RD 2 2 2 2 2 Antiaging agent FR 1 1 1 1 1 N330 carbon black 60 40 40 50 50 quick press carbon b...

Embodiment 3

[0050]The extrusion swell rate of Example 3 is 10.3%, while the extrusion swell rate of this type of rubber compound for water pipes is generally 17%-18%, which is about 40% lower than that of common rubber compounds;

[0051] The shrinkage tracking data of the extruded inner and outer diameters of Example 3 are as follows:

[0052] Table 3 The shrinkage data table of the sulfur vulcanized EPDM composition prepared in Example 3

[0053]

[0054] From attached Figure 1-2 As can be seen from the comparison, the products of the present invention are made with respect to common sizing materials:

[0055] Products made of ordinary rubber materials will bloom after 6 months of storage.

[0056] The rubber product of the present invention: there is no blooming phenomenon after being parked for 10 months.

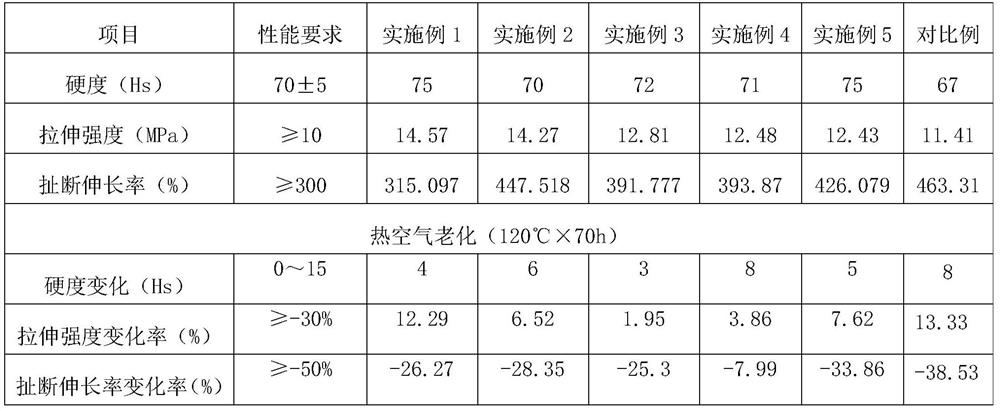

[0057] As can be seen from the above examples, the rubber composition of the present invention is resistant to aging, 3# oil, coolant, low temperature, and ozone, and has th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com