A method for separating diesel fraction from light raw oil

A raw oil and light technology, applied in the field of petroleum processing, can solve the problems of increasing the yield of coke and dry gas, deteriorating the quality of diesel oil, etc., and achieve the effects of reducing the content of aromatic hydrocarbons, reducing the amount of catalytic processing, and reducing the output of coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

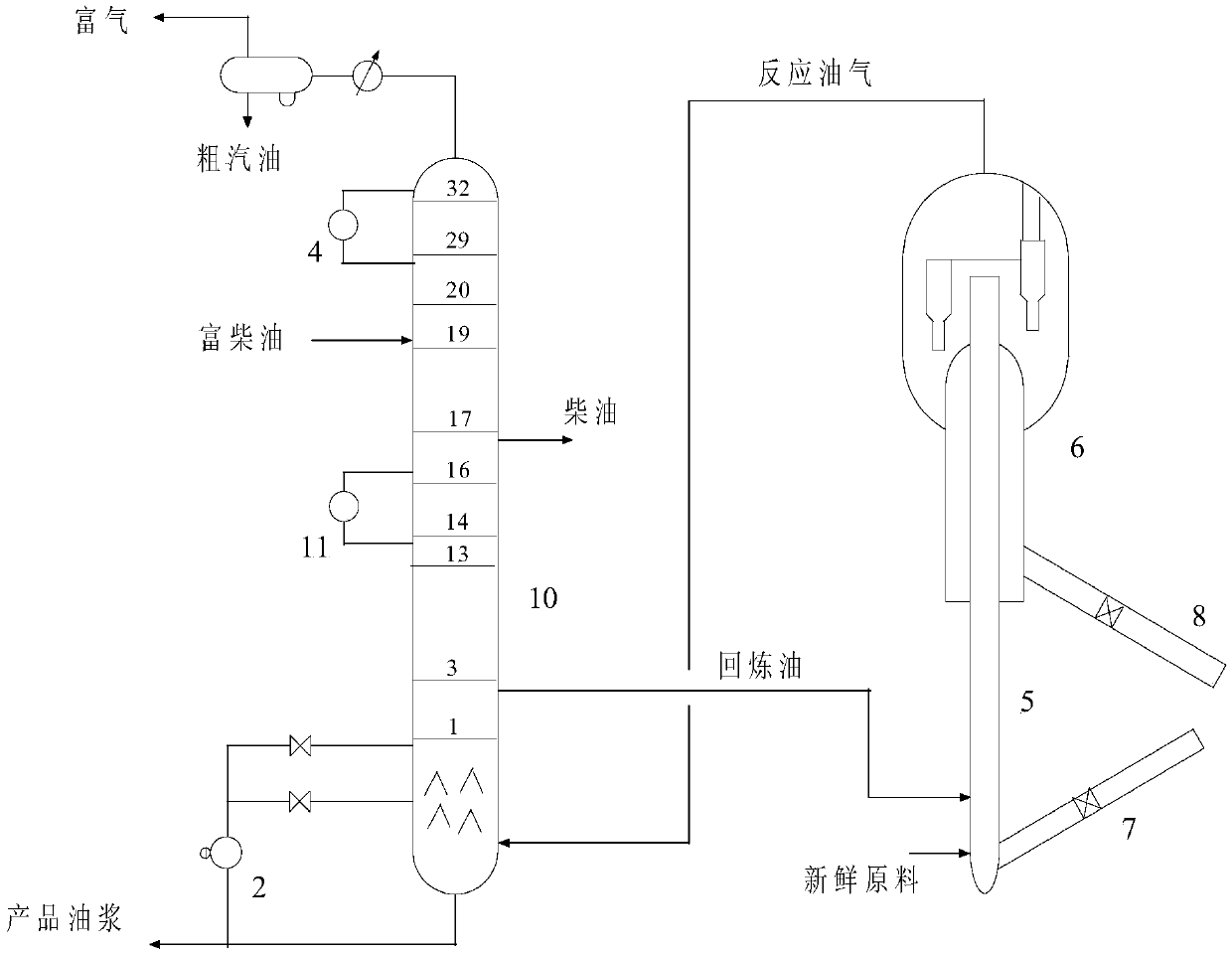

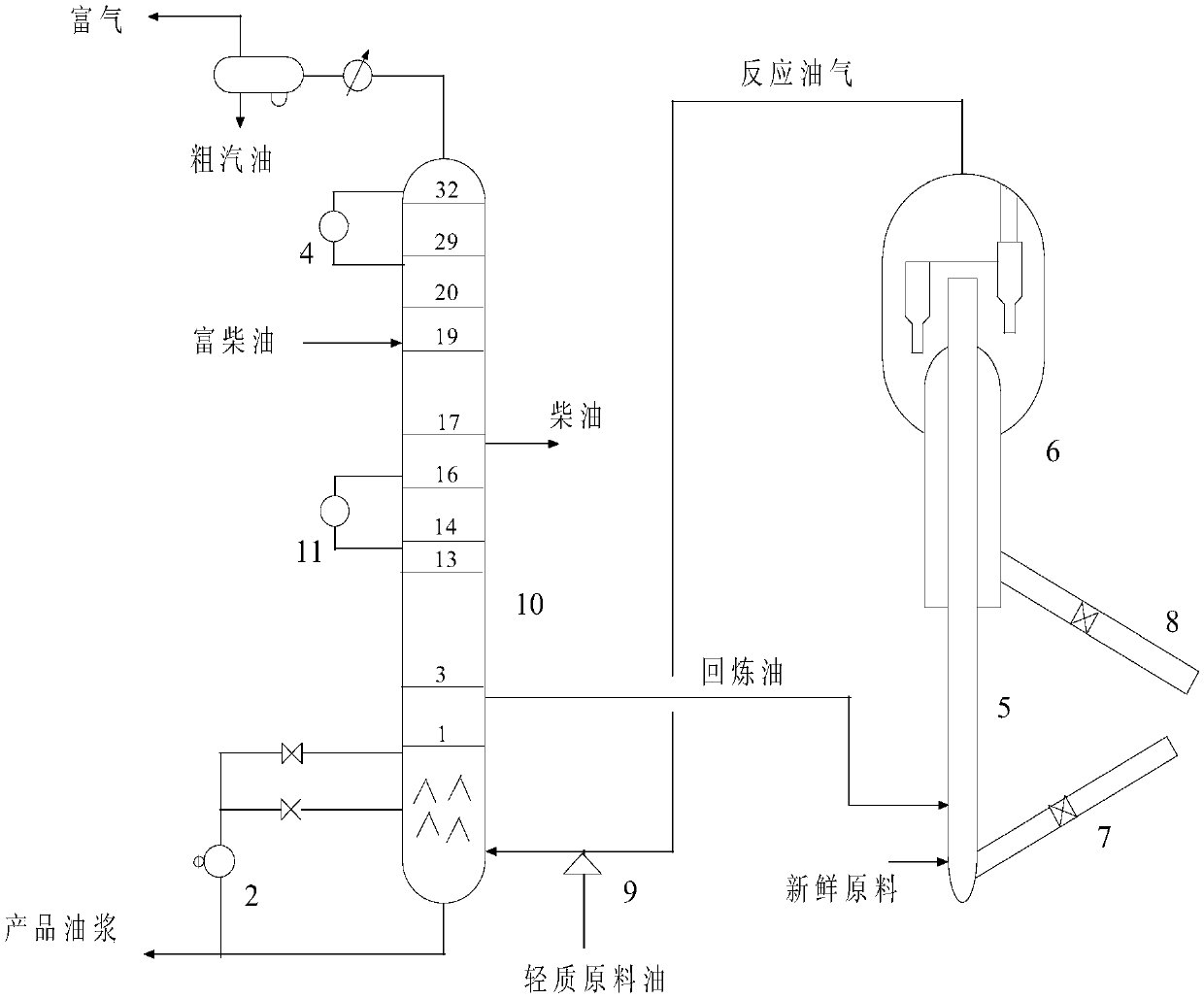

[0043] This example is a new process for separating light raw material oil from the superheating section of the main fractionating tower of the catalytic cracking unit to avoid repeated processing of diesel fractions. Its process is as follows figure 2 shown. details as follows:

[0044]First, the reaction mechanism of catalytic cracking is extremely complex, so the examples only calculate the distribution of the feed amount of the fractionation tower and the riser. Separating the diesel fraction does not participate in the riser reaction, which can reduce coke and dry gas production, reduce the concentration of aromatic components in diesel, and increase its cetane number.

[0045] The fresh raw material (190t / h) without light raw material minus first-line oil (24t / h) is heated to 220°C once through the circulating oil slurry, and the recycled oil (64t / h, 334°C) from the lower part of the main fractionation tower 10 is sequentially processed The riser reactor 5, under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com