A kind of modified insulating paper, its preparation method and oil-impregnated insulating paper medium body

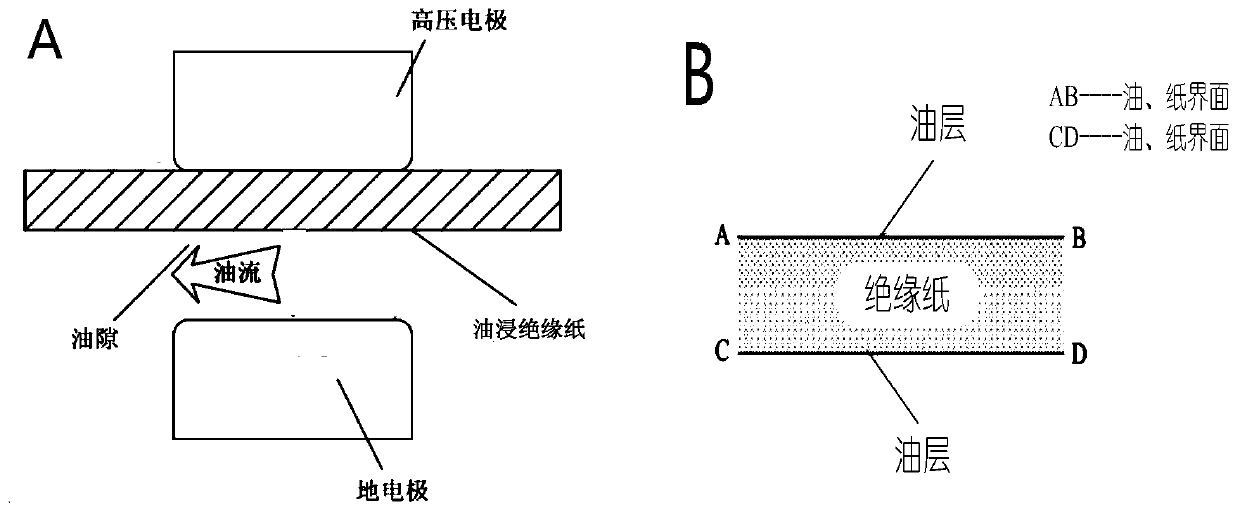

A technology of insulating paper and modification, which is applied in the field of its preparation, modified insulating paper, and oil-impregnated insulating paper medium body, can solve the problem of charge accumulation at the oil-paper insulation interface, and cannot effectively solve the problem of accumulation, and achieves Effects of space charge reduction, interface charge suppression, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a method for preparing modified insulating paper described in the above technical solution, comprising the following steps:

[0044] The Al target is subjected to magnetron sputtering in a mixed gas environment, and deposited on an insulating paper substrate to form a micro-nano structure Al 2 o 3 Film layer, obtains modified insulating paper;

[0045] The mixed gas is argon and oxygen.

[0046] Among them, the insulating paper and micro-nano structure Al 2 o 3 The type, thickness, etc. of the film layer are consistent with the above-mentioned technical solution, and will not be repeated here.

[0047] According to the present invention, an Al target is used for magnetron sputtering; in the present invention, the purity of the Al target is preferably above 5N (ie 99.999%). The present invention has no special limitation on the sputtering distance of the magnetron sputtering, that is, the distance between the target and the substr...

Embodiment 1

[0060] 1.1 Preparation of modified insulating paper:

[0061] Using insulating paper (provided by State Grid Nanrui Borui Transformer Factory, with a thickness of 0.5mm) as the substrate, Al as the target, and the sputtering distance is 10cm, the sputtering chamber is evacuated to 4.5×10 -3 Pa, into the sputtering chamber into argon and oxygen, the argon gas pressure is 1Pa, the oxygen flow rate is 20sccm, sputtering 90min under the sputtering power 110W, on the surface of one side of the insulating paper substrate, a light white substance is deposited. Nanostructured Al 2 o 3 film layer to obtain modified insulating paper S'.

[0062] 1.2 Appearance and microscopic characterization:

[0063] (1) The appearance of unsputtered insulating paper and modified insulating paper after sputtering is as follows image 3 As shown, among them, image 3 a is modified insulating paper, image 3 b is the unmodified insulating paper. Compared with the unmodified insulating paper, the s...

Embodiment 2

[0078] 2.1 Preparation of oil-impregnated insulating paper medium body: The insulating oil (Xinjiang Karamay 25# insulating oil) is dehydrated and degassed to meet the national standard requirements of GB2536-2011 unused mineral insulating oil for electrical fluid transformers and switches. Al 2 o 3 Nano-modified insulating paper [that is, the insulating paper contains Al 2 o 3 Nanoparticles, prepared by the High Pressure Laboratory of Chongqing University, according to the preparation method of the document "Effect of Nano-Al2O3 on the Thermal Aging PhysicalProperties of Insulating Paper" (2016 International Conference on Condition Monitoring and Diagnosis, 2016, pp.40-43.) get] and without Al 2 o 3 Dry the insulating paper before nano-modification to keep the water content below 1%; then vacuum impregnate the insulating paper with insulating oil at a vacuum degree of 50Pa and 40°C, and continue to immerse in oil for 48 hours to obtain an oil-impregnated insulating paper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com