A kind of EPDM rubber-based DC cable accessory material and preparation method thereof

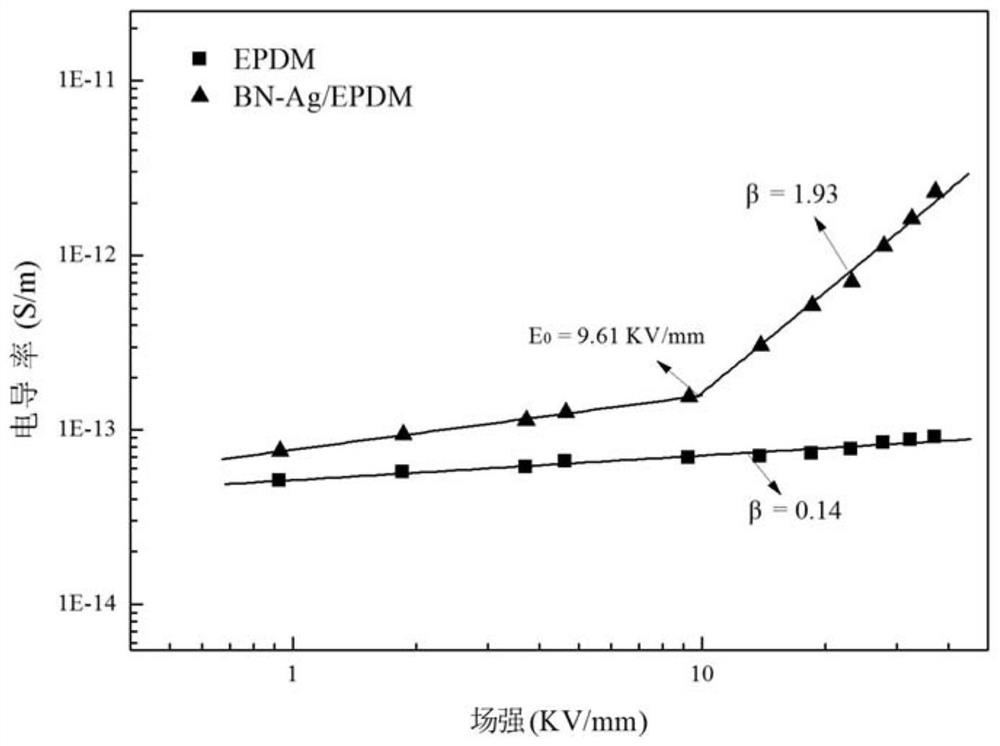

A technology of EPDM and DC cables, which is applied in the field of DC cable accessories materials, can solve the problems of reducing the breakdown field strength of insulating materials and affecting the safe operation of cable accessories, so as to reduce the probability of failure and stabilize the DC breakdown field Strong, homogenized internal electric field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

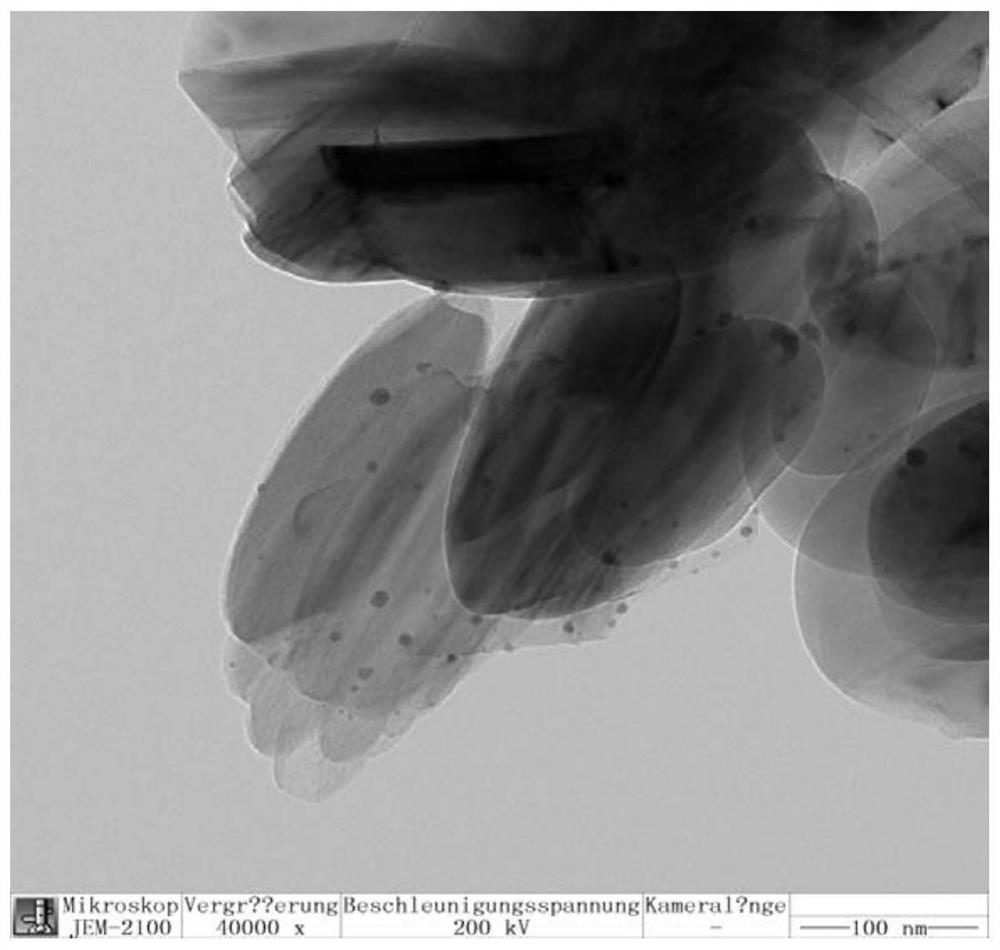

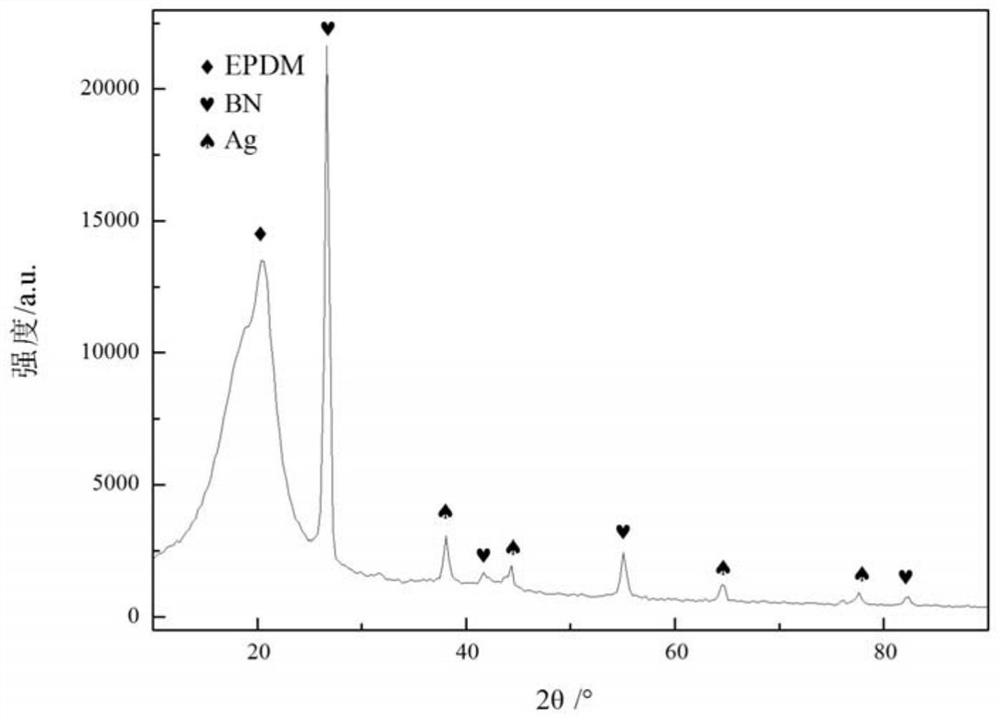

[0030] A preparation method of EPDM-based DC cable accessory material, comprising the steps of:

[0031] Step 1. Weigh boron nitride, absolute ethanol, and deionized water respectively according to a certain material-to-liquid ratio, add the weighed boron nitride, absolute ethanol, and deionized water into a beaker and stir, and then put it into an ultrasonic disperser Mid-ultrasonic, obtain boron nitride suspension A, stand-by;

[0032] Step 2. Weigh the boron nitride suspension A, formic acid, and 3-aminopropyltriethoxysilane prepared in step 1 according to a certain mass ratio, and weigh the boron nitride suspension A prepared in step 1. Suspension A, formic acid, and 3-aminopropyltriethoxysilane were added to a beaker, stirred, suction filtered, washed, and dried to obtain modified boron nitride for use;

[0033] Step 3. Grinding the modified boron nitride prepared in step 2, adding a certain volume of absolute ethanol, and putting it into an ultrasonic disperser for ultr...

specific Embodiment approach 2

[0050] A preparation method of EPDM-based DC cable accessory material, comprising the steps of:

[0051] Step 1. Weigh boron nitride, absolute ethanol, and deionized water respectively according to a certain material-to-liquid ratio, add the weighed boron nitride, absolute ethanol, and deionized water into a beaker and stir, and then put it into an ultrasonic disperser Mid-ultrasonic, obtain boron nitride suspension A, stand-by;

[0052] Step 2. Weigh the boron nitride suspension A, formic acid, and 3-aminopropyltriethoxysilane prepared in step 1 according to a certain mass ratio, and weigh the boron nitride suspension A prepared in step 1. Suspension A, formic acid, and 3-aminopropyltriethoxysilane were added to a beaker, stirred, suction filtered, washed, and dried to obtain modified boron nitride for use;

[0053] Step 3. Grinding the modified boron nitride prepared in step 2, adding a certain volume of absolute ethanol, and putting it into an ultrasonic disperser for ultr...

specific Embodiment approach 3

[0060] According to the preparation method of the EPDM rubber-based DC cable accessory material described in the second specific embodiment, the solid-liquid ratio of boron nitride, absolute ethanol, and deionized water in step 1 is 1g: 90-100ml: 4-7ml , the power of the ultrasonic disperser is 490W, and the ultrasonic time is 400min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com