Rotatably-welding rivet and riveting method thereof

A technology of spin welding and rivets, applied in rivets and other directions, can solve the problems of prolonging production time, increasing the structural deformation of thin-walled plates or related components, and being unable to ensure sealing, etc., and achieves the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the technical solutions of the present application, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0034] The orientation terms such as up, down, left, right, front and rear in this application document are established based on the positional relationship shown in the drawings. If the drawings are different, the corresponding positional relationship may also change accordingly, so this should not be understood as limiting the scope of protection.

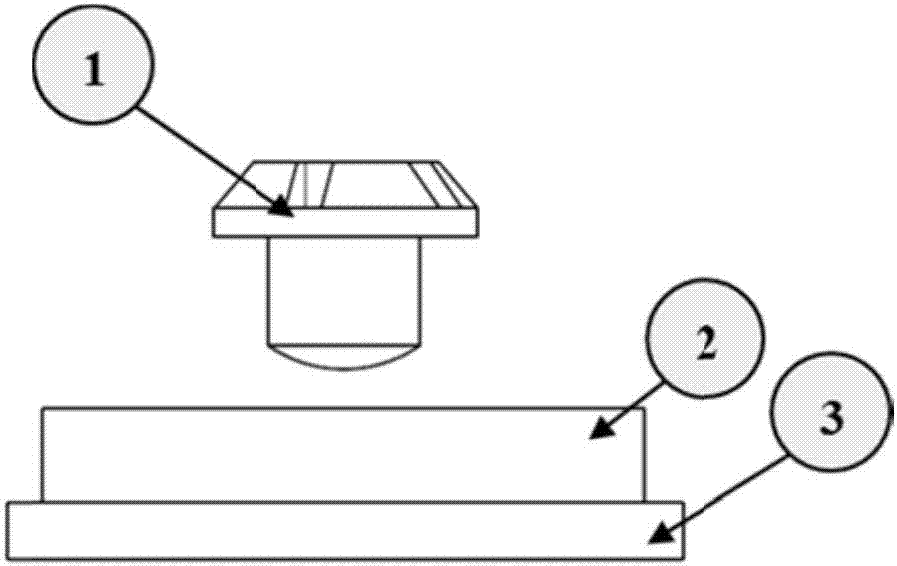

[0035] This embodiment describes a rotary welding rivet, hereinafter referred to as rivet 1, which is mainly used for the connection of light metal plates, such as aluminum plates, aluminum alloy plates, magnesium aluminum alloy plates and other light metal plates and steel plates, such as figure 1 The connection of light metal sheet 2 and steel sheet 3 is shown.

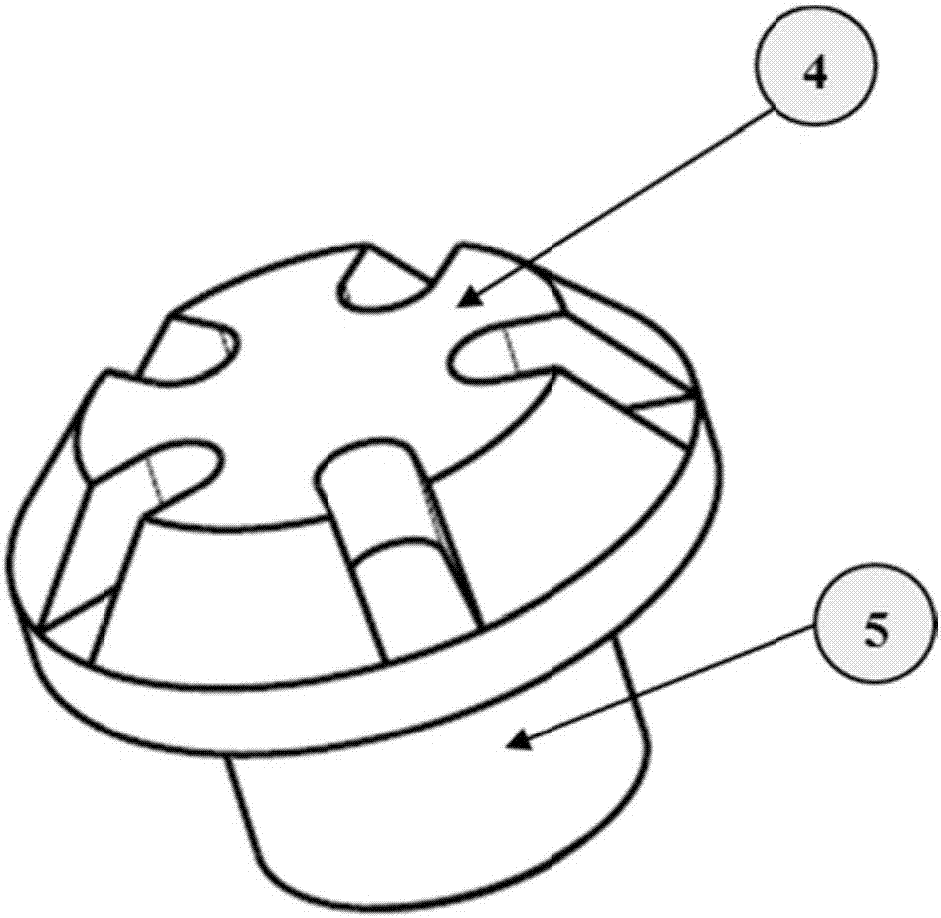

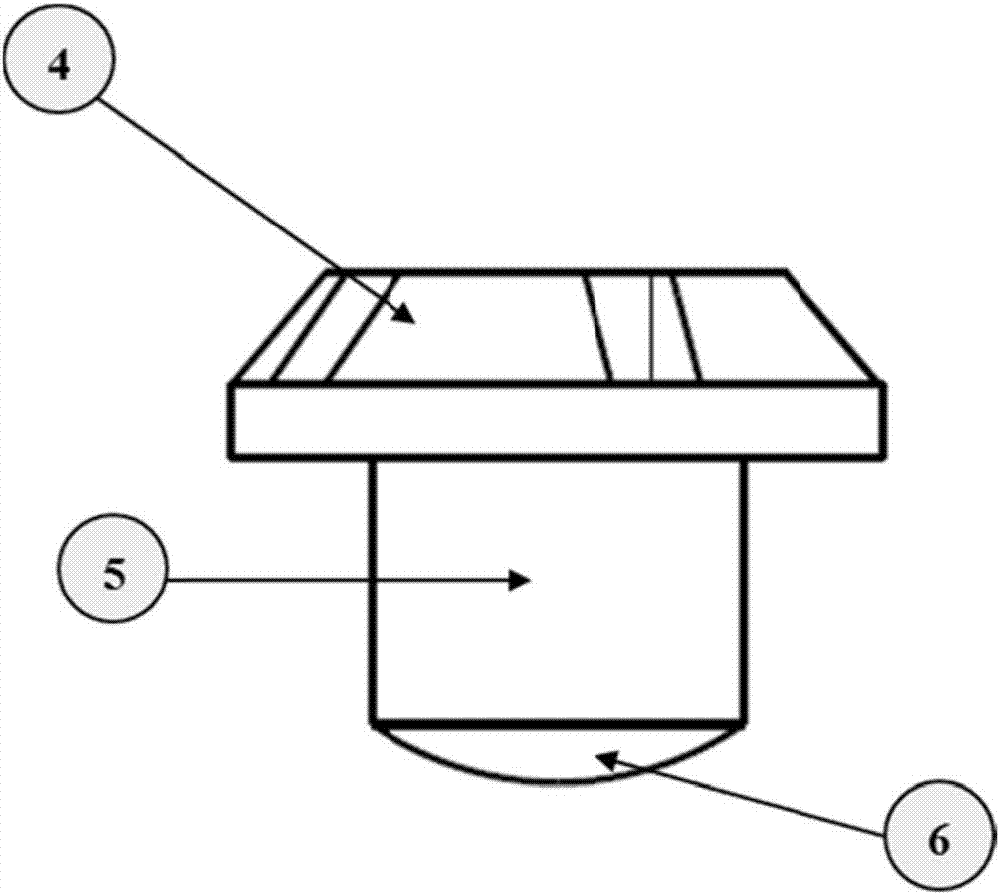

[0036] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com