Swing frame mechanism of dynamic calibration equipment

A dynamic calibration and equipment technology, applied in the direction of transmission, mechanical equipment, belt/chain/gear, etc., can solve the problems of unfavorable conduction, belt tension change, belt stretching, etc., and achieve stable conduction, easy operation, and extended The effect of using time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

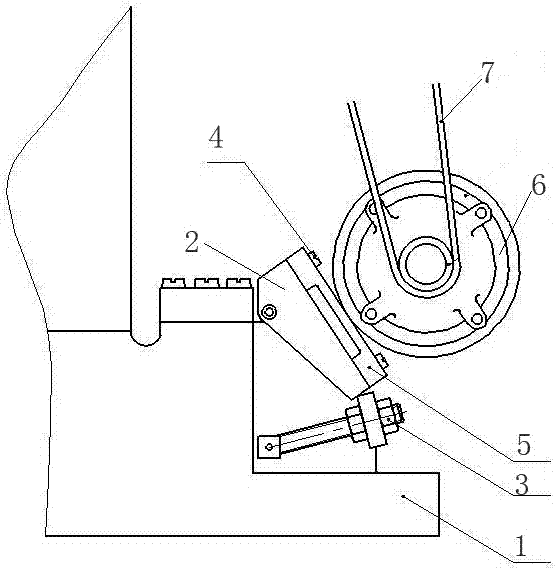

[0010] Combine below figure 1 Specific examples:

[0011] The swing frame mechanism for dynamic calibration equipment includes a frame body 1. A swing frame 2 is provided at the upper end of the frame body 1. One end of the swing frame 2 is hingedly arranged on the frame body 1, and the other end of the swing frame 2 is connected with The adjusting nut 3 is connected; the swing frame 2 is provided with an adjusting plate 5 through the fixing screw 4, the adjusting plate 5 can be slid on the swing frame through the fixing screw, the adjusting plate 5 is connected with the motor 6, and the output end of the motor 6 is connected There is belt 7; when the belt needs to adjust the tension, first loosen the fixing screw, adjust the adjustment nut, make the swing frame swing downward, adjust to the specified position, lock the adjustment nut, then fix the fastening screw, and adjust the motor to The desired location.

[0012] Preferably, the adjusting nut is hingedly arranged on the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com