Intensive direct current deicing device topology structure for wind power plant

A technology of DC ice melting and topological structure, which is applied in the direction of circuit devices, wind power generation, and cable installation, etc., and can solve the problems of large differences in wind farm collector lines, small capacity of ice melting devices in rural power grids, and large footprints , to achieve the effect of meeting the line's ice-melting capacity requirements, wide-range current regulation capability, and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

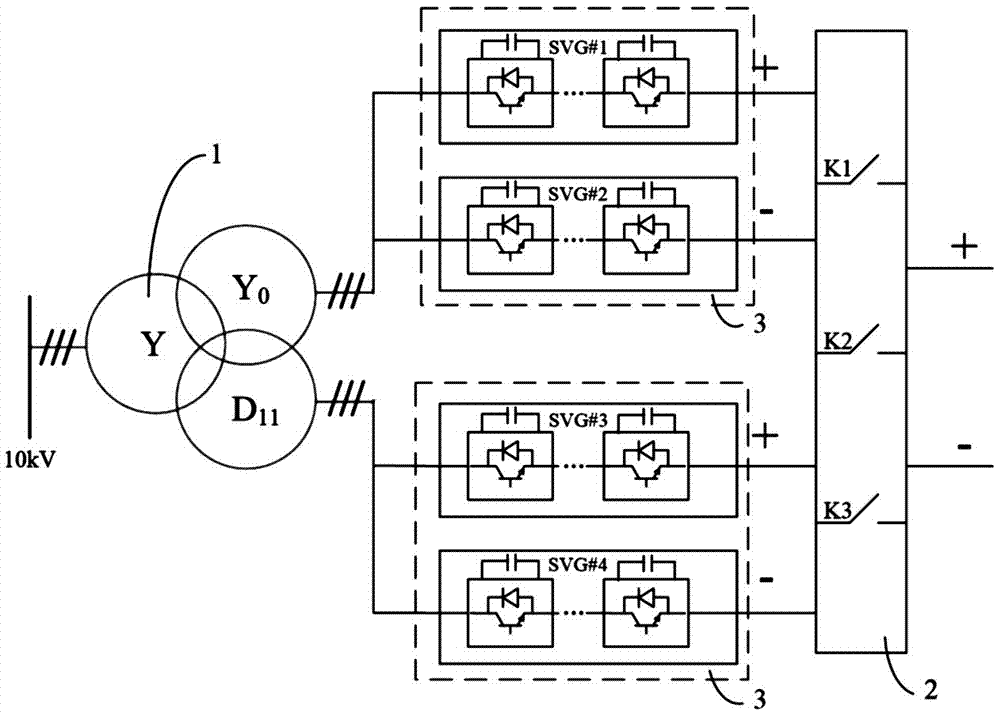

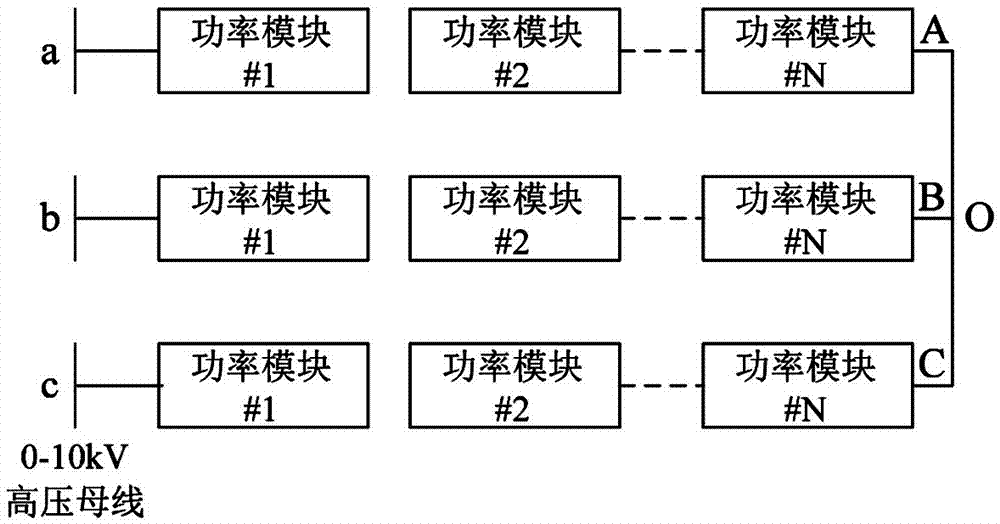

[0019] Such as figure 1 As shown, the topological structure of the intensive DC ice-melting device for wind farms in this embodiment includes a three-winding ice-melting transformer 1, a series-parallel switch 2 and two sets of dynamic reactive power compensation units 3, and three windings of the three-winding ice-melting transformer 1 Including the primary winding and two secondary windings, the dynamic reactive power compensation unit 3 includes two SVGs (dynamic reactive power compensation devices) arranged in parallel, the primary winding of the ice-melting transformer 1 is connected to the power grid, and the secondary windings are respectively connected to different The two SVGs of the dynamic reactive power compensation unit 3 are connected, the output ends of each SVG are respectively connected to the input ends of the series-parallel switch 2, and the output ends of the series-parallel switch 2 are connected to the line to be deiced. Functionally, this embodiment ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com