Novel dead-zone compensation method and system based on pulse optimization

A dead zone compensation, a new type of technology, applied in the direction of output power conversion devices, electrical components, etc., can solve the problems of high requirements for control chips, false compensation, and insufficient compensation, achieve high detection accuracy, improve acceleration performance, and solve The effect of poor dynamic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Concrete steps of the inventive method:

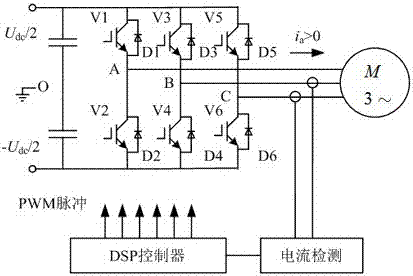

[0034] Step 1. The main circuit of the electric vehicle drive motor is generally powered by a three-phase bridge voltage source inverter, and the power supply is a DC power supply. Due to the turn-on and turn-off delays of the actual power switching devices, in order to prevent the upper and lower bridge arms from being directly connected, a period of dead time is usually added during the switching action. The existence of the dead zone causes an error between the actual output voltage of the inverter and the target voltage, resulting in distortion of the phase voltage and phase current of the motor, zero current clamping, torque and speed pulsation and other dead zone effects. figure 1 Shown is the main circuit where the three-phase voltage type inverter is connected to the motor. It is stipulated that the current flowing from the inverter to the motor is positive, and vice versa.

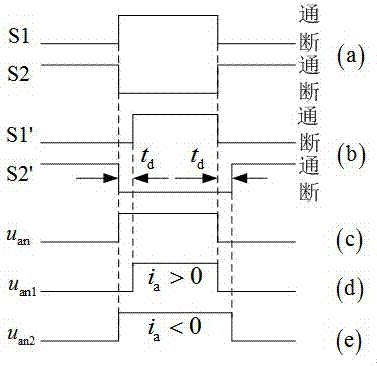

[0035] figure 2 Shown is the waveform of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap