Stamping parts forming method

A forming method and technology of stamping parts, which are applied in the field of stamping part forming, can solve problems such as the inability to meet the quality requirements of stamping parts, low utilization rate of materials in the stamping forming process, and difficulty in forming the stamping part 1 as a whole. The effect of high production efficiency and simple molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

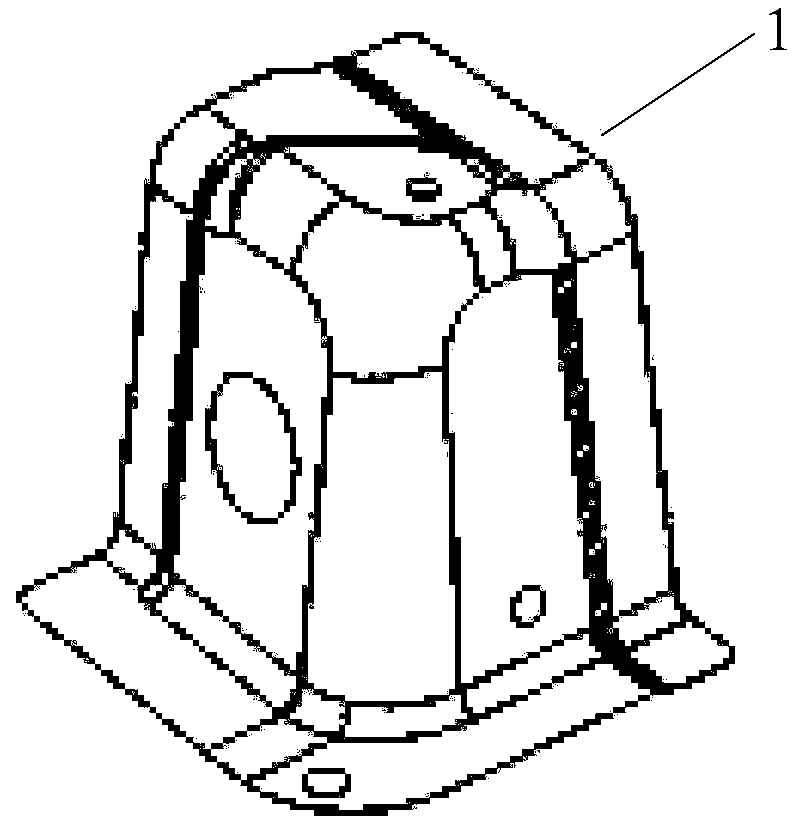

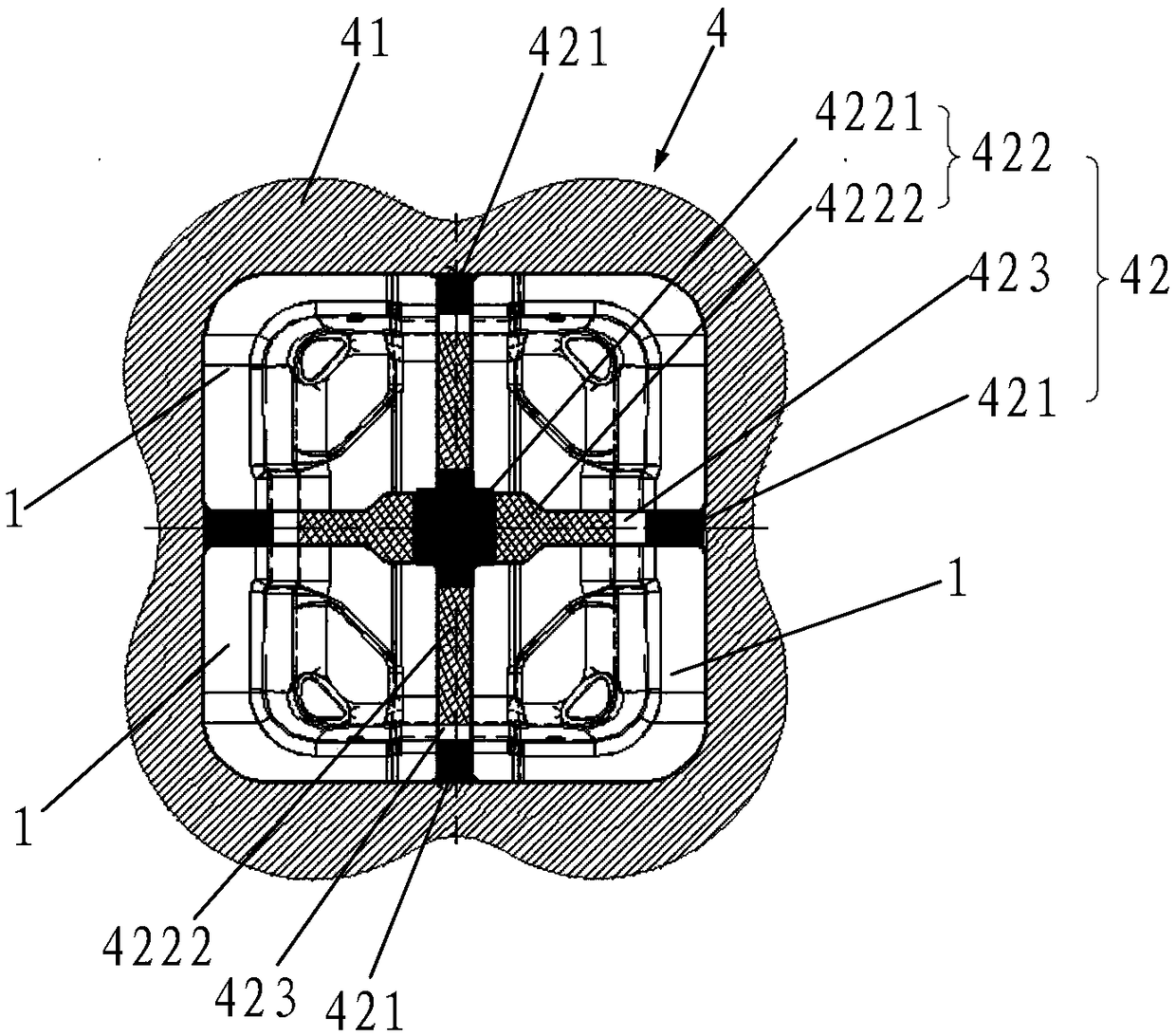

[0029] Embodiment of the present invention: a method for forming a stamping part. For ease of understanding, the stamping part 1 selected in this embodiment is as follows figure 1 The sill connecting plate of the quarter box structure shown, and the left and right sill connecting plates are symmetrical structures, and the side and bottom surfaces need to be processed with process holes. In the forming method, four stamping parts 1 are combined and stretched together, and the four stamping parts 1 are combined in pairs. The process mainly includes several processes such as blanking, stretching, trimming and punching, and is carried out according to the following steps:

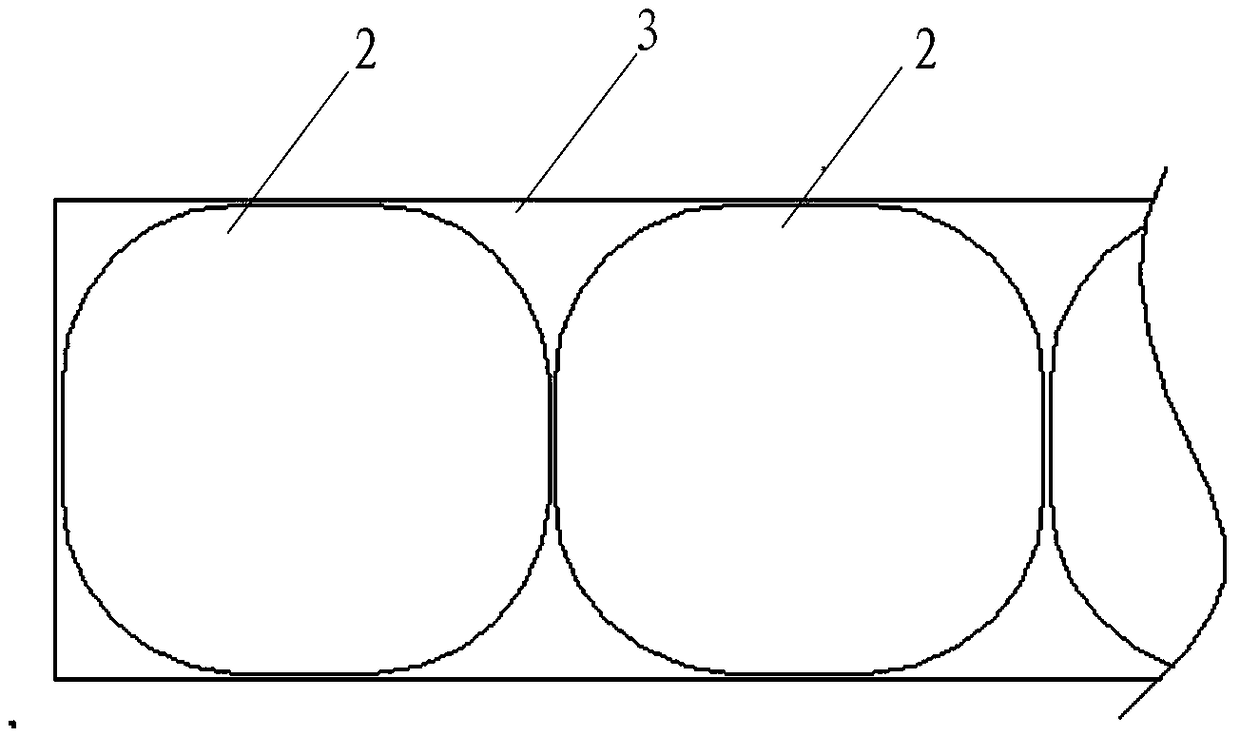

[0030] 1. Blanking, according to the size of the stamping part 1, determine the size of the stretched sheet 2 required for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com