Intelligent cutting device for aluminum alloy board

An aluminum alloy sheet, intelligent cutting technology, applied in grinding/polishing safety devices, metal processing equipment, grinding machines, etc., can solve problems such as affecting work efficiency, large cutting errors, and low cutting accuracy, and achieve uniformity, The effect of reducing the burden of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

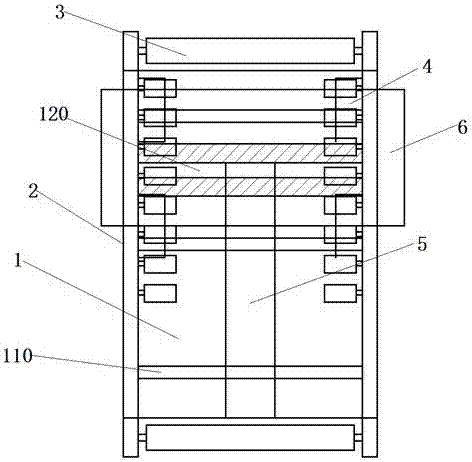

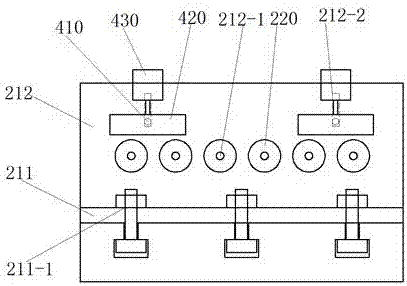

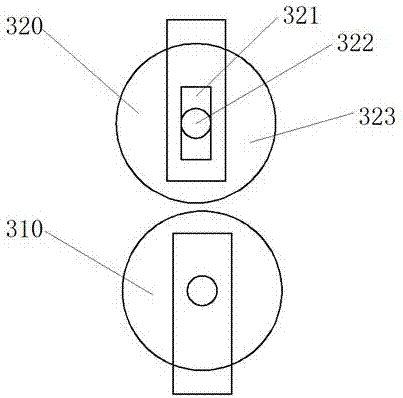

[0023] Please refer to Figure 1-Figure 5 , figure 1 A schematic diagram of the overall structure of an aluminum alloy plate intelligent cutting device is provided for the present invention; figure 2 Provide the installation schematic diagram of installation frame for the present invention; image 3 Provide the installation diagram of stretching and flattening mechanism for the present invention; Figure 4 Provide the installation diagram of feeding mechanism for the present invention; Figure 5 A structural schematic diagram of a cutting device is provided for the present invention.

[0024] Specifically, this embodiment provides an intelligent cutting device for aluminum alloy sheets, which is characterized in that it includes: a chassis 1, an installation frame 2, a stretching and flattening mechanism 3, a pressing mechanism 4, a feeding mechanism 5, and a cutting device 6; , the chassis 1 is processed equidistantly provided with several chute 110, and cutting bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com