Eight-guide bar double-jacquard multi-signal warp knitting fabric

A warp knitted fabric and double jacquard technology, which is applied in the directions of warp knitting, knitting, textiles and papermaking, can solve the problem of high price and achieve the effect of increasing the three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

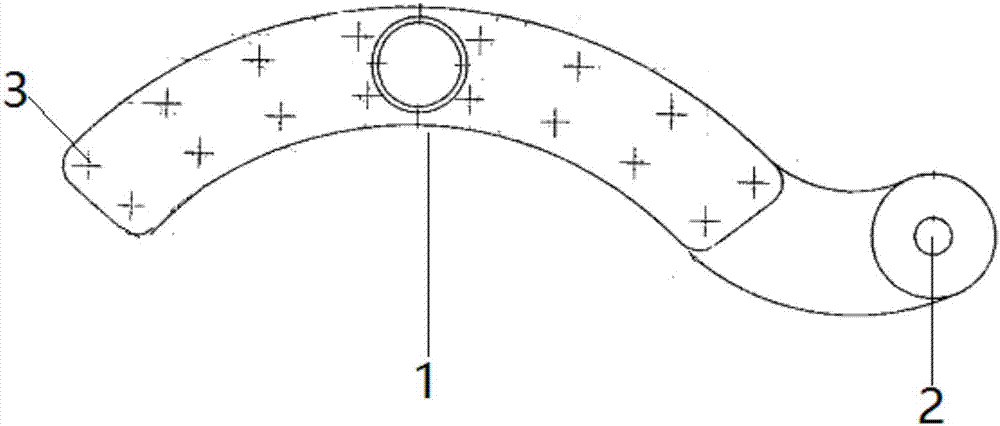

[0019] Please see attached figure 1 , a warp-knitted fabric with eight bars and double jacquard signals, is a sandwich structure, specifically a surface layer, a middle layer and a bottom layer, and the surface layer and the bottom layer are connected through the middle layer; and the surface layer and the bottom layer are provided with the same or different Jacquard.

[0020] The material of the bottom layer, the surface layer and the bottom layer is fiber material, which can be polyester fiber, nylon fiber and spandex fiber or the like.

[0021] The invention discloses a method for processing warp-knitted fabric with eight-bar double jacquard signals. The warp-knitted fabric is obtained by combining the warp-knitting technique and the weaving technique of jacquard jacquard.

[0022] The raw material is fiber material, the warping is 150-560 pieces, and the way of threading is full threading or empty threading and interweaving.

[0023] The thickness of the fabric is 1-8mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com