Dotting and lineation head for clothes processing dotting and lineation machine

A scribing machine and scribing technology, which is used in the marking of textile materials, textiles and paper making, etc., can solve the problems of easy errors, strong speciality of the scribing head, and high technical content, and achieves sensitive and convenient use and high precision. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

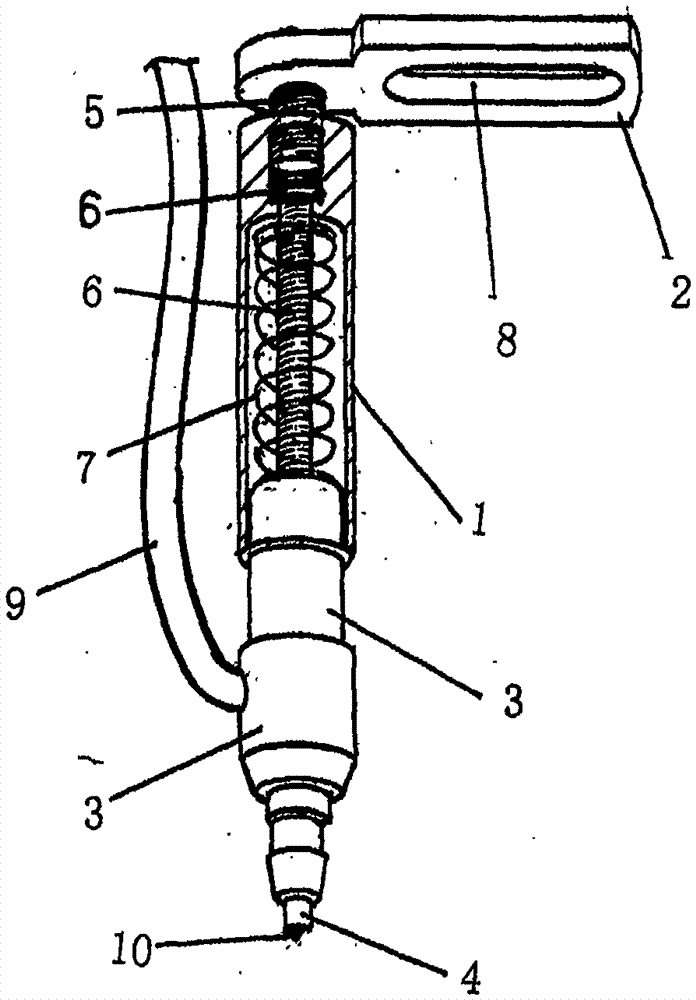

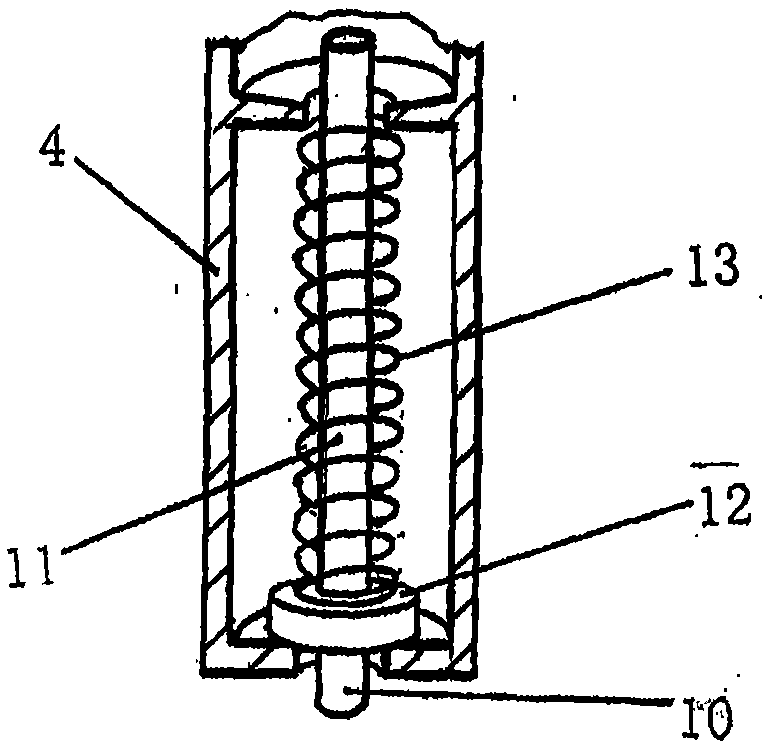

[0013] figure 1 , 2 Shown: the dot-dash head used by the garment processing dot-dash machine is provided with a universal fixed plate 2 connected by screws 5 above the fixed body 1, and an elastic dot-dash body 3 is installed below, and a dot-dash body 3 is installed at the bottom of the dot-dash body 3. A bit draws ink head 4, and this ink outlet head 4 is equipped with elastic plug 10 for opening the seal, and one side is provided with connecting hose 9 that can be connected with the ink cartridge. The universal fixing plate 2 is provided with a bar hole 8 for universal adjustment. The elastic dot-and-dash body 3 is inserted into the fixed body 1, and the two are connected and fixed by a built-in screw 6, and the screw rod 6 is covered with a spring A7 for allowing the elastic dot-and-dash body 3 to bounce outward. Dot-and-dash ink dot 4 is provided with an ejector rod 11 that discharges ink through the top of the dot-and-dash head, and a block 12 is provided below the eje...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap