Heat storage type radiant tube combustor burner with replaceable burner brick

A regenerative radiant tube and burner brick technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of high flame temperature, inconvenient maintenance and replacement, burner brick burning, etc., and achieve economical improvement. Benefit, avoid deformation, save radial space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038]Take the burner required for a 140KW external single regenerative radiant tube burner as an example.

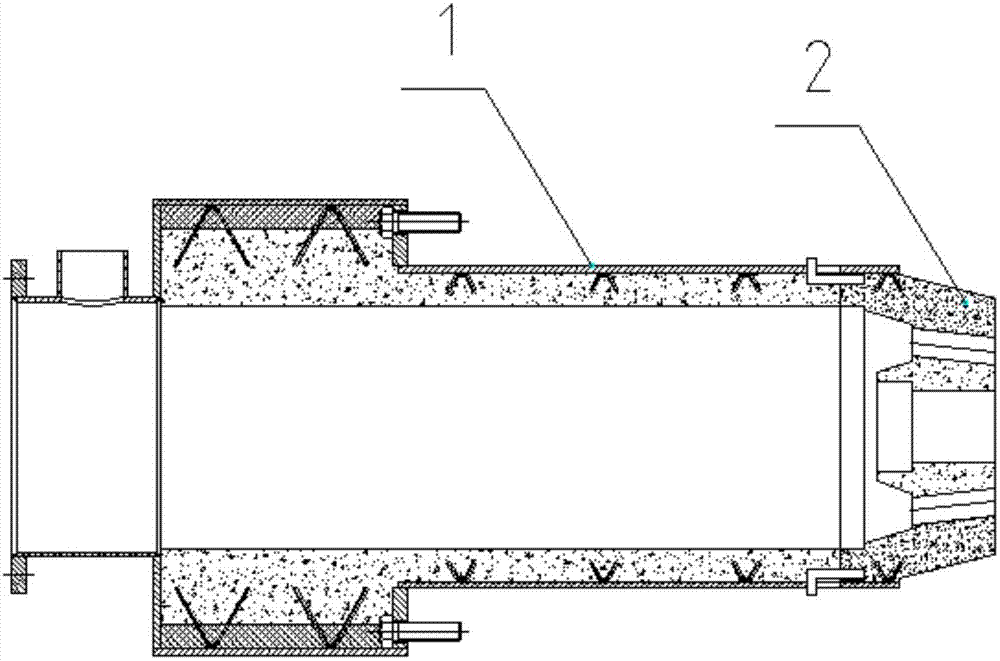

[0039] Its form is as figure 1 shown.

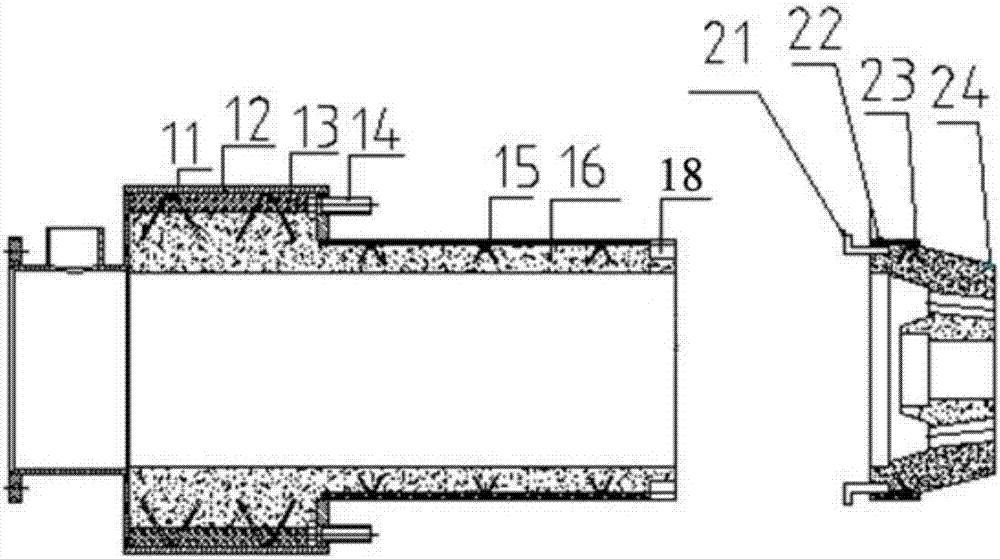

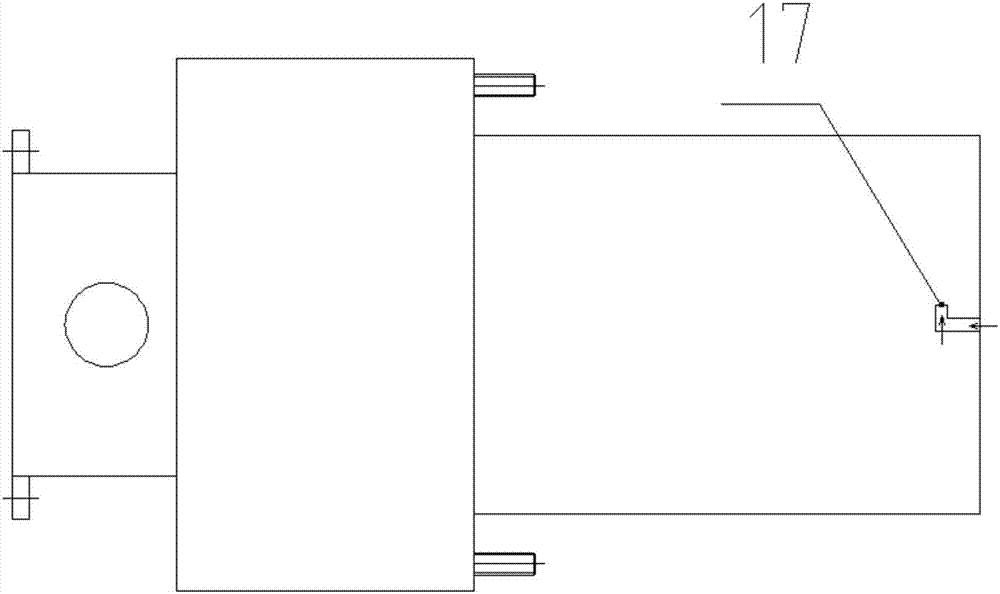

[0040] Such as figure 2 and image 3 As shown, the burner cavity 1 includes a large anchor hook 11, a cavity weldment 12, a fiber blanket 13, a bolt 14, a small anchor hook 15 of the burner cavity, a lightweight castable layer 16, and an L-shaped half-through groove 17 And the recess 18, the burner brick 2 includes an L-shaped connector 21, a sleeve 22, a small anchor hook 23 of the burner brick, and a heavy castable layer 24.

[0041] Such as figure 2 , 3 As shown, the cavity weldment 12 is welded by heat-resistant steel according to the drawings. The large anchor hook 11 and the small anchor hook 15 of the burner cavity are welded with the cavity weldment 12 . The fiber blanket 13 is laid on the inner wall of the cavity welding part 12 . The bolt 14 is sealed and welded with the cavity weldment 12 . The lightweight ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com