PCB (Printed Circuit Board) automatic detector

A technology for PCB boards and inspection machines, which can be used in measurement devices, optical testing of flaws/defects, and material analysis by optical means, which can solve the problems of low efficiency and low scanning image quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] Please refer to the drawings, in which the same component symbols represent the same components, and the principle of the present invention is exemplified by being implemented in a suitable computing environment. The following description is based on the illustrated specific embodiments of the present invention, which should not be regarded as limiting other specific embodiments of the present invention that are not described in detail herein.

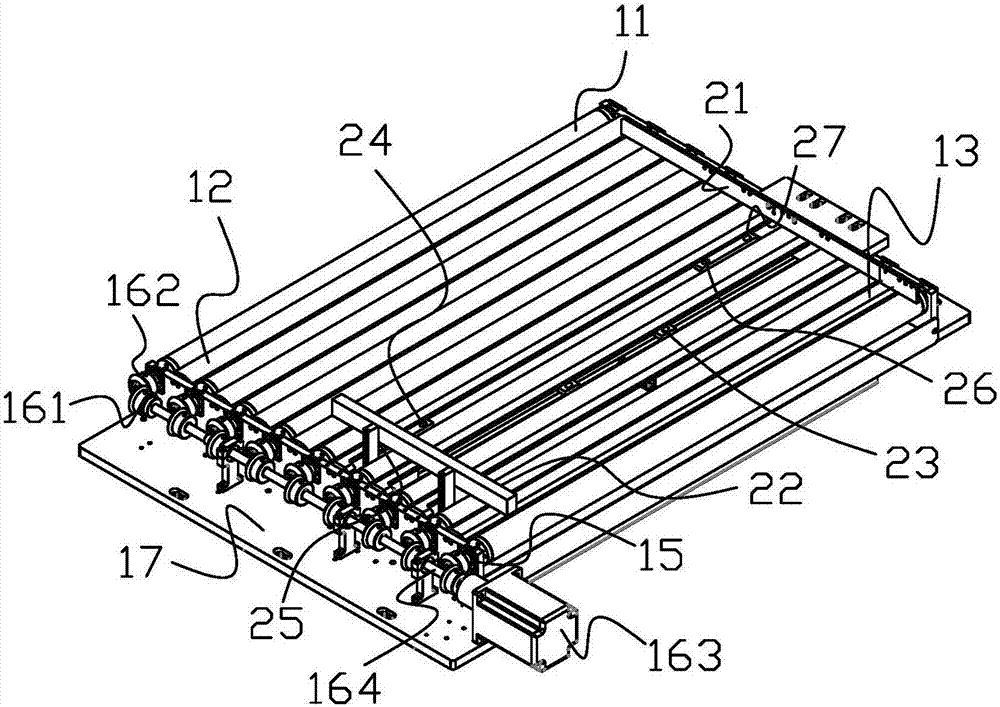

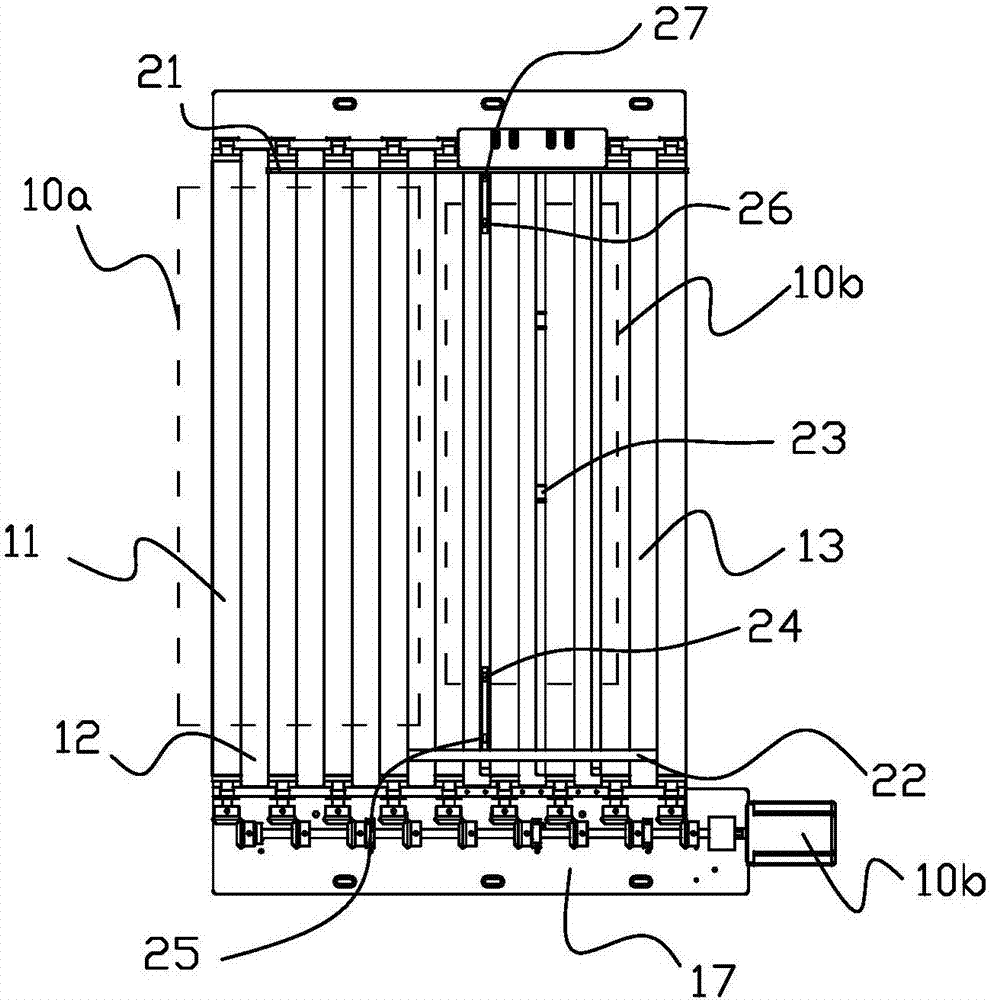

[0091] Please refer to figure 1 , figure 1 It is a schematic front view of the preferred embodiment of the PCB board automatic inspection machine of the present invention. The preferred embodiment of the PCB board automatic inspection machine of the present invention includes a transmission device having a feeding position 10a, a first correction position 10b, a second correction position 20c, a first detection position 20d and a second detection position 20e, and a first correction mechanism 20. The second calibration mechanism 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com