Bus duct with self-cooling circulation system

A circulating system and busway technology, applied in cooling busbar devices, fully enclosed busbar devices, coatings, etc., can solve the problems of poor heat dissipation performance, affecting normal work, reducing service life, etc., achieving good heat dissipation effect, simple structure, Operational failure prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

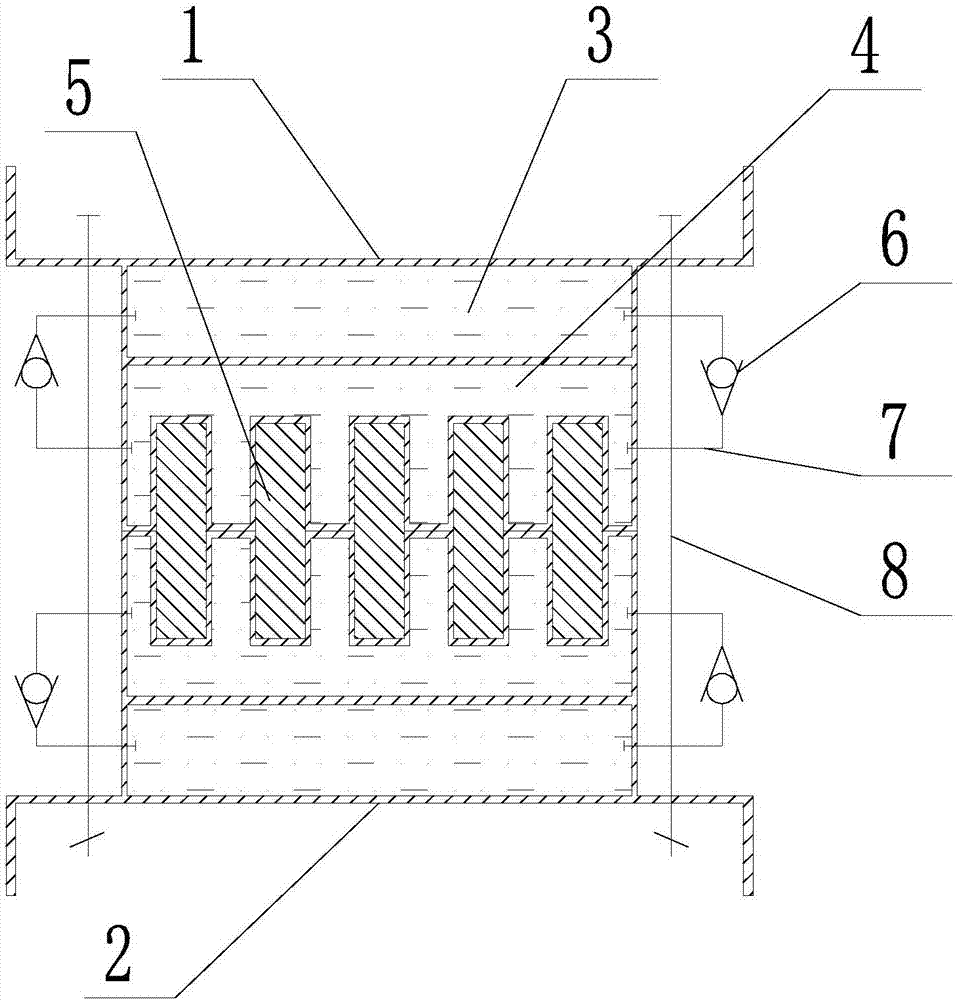

[0024] This embodiment provides a busway with a self-cooling circulation system, which includes a first busway 1 with a cooling circulation system inside the first busway 1, and is characterized in that: the cooling circulation system includes a first busway 1 from the top There are a first cavity 3 and a second cavity 4 for storing cooling liquid in sequence from the bottom. A positioning slot 5 for placing busbar conductors is opened on the lower end of the first busbar slot 1, and the positioning slot 5 is along the first busbar slot 1. There are five in the width direction. Opposite check valves 6 are provided on both sides of the first busway 1 along its length. The interfaces of the check valves 6 are connected to the first cavity 3 and the second cavity through the pipe 7 respectively. The cavities 4 are connected, the cooling liquid on one side can only flow from the first cavity 3 to the second cavity 4, and the cooling liquid on the other side can only flow from the se...

Embodiment 2

[0033] This embodiment provides a busway with a self-cooling circulation system, and the structure of the busway with a self-cooling circulation system is exactly the same as that of the first embodiment;

[0034] The surfaces of the first cavity and the second cavity are coated with a corrosion-resistant high-strength coating. The components of the corrosion-resistant high-strength coating are calculated in parts by weight: phyllite: 27 parts, lime alkali glaze: 20 parts, Tourmaline: 18 parts, copper oxide: 17 parts, aluminum oxide: 13 parts, acrylic emulsion: 32 parts, nitrile latex: 23 parts, polyurethane emulsion: 13 parts, alkyd resin: 15 parts, ethyl acetate : 25 parts, aliphatic sulfonate: 15 parts, paraffin: 3 parts, alkyl aryl sulfonate: 16 parts, PVC resin powder: 15 parts, talc: 18 parts, clay: 28 parts;

[0035] The preparation process of the corrosion-resistant high-strength coating is carried out in the following steps:

[0036] Step 1: Mix phyllite, lime alkali glaze,...

Embodiment 3

[0041] This embodiment provides a busway with a self-cooling circulation system, and the structure of the busway with a self-cooling circulation system is exactly the same as that of the first embodiment;

[0042] The surfaces of the first cavity and the second cavity are coated with a corrosion-resistant high-strength coating. The components of the corrosion-resistant high-strength coating are calculated in parts by weight: phyllite: 26 parts, lime alkali glaze: 19 parts, Tourmaline: 17 parts, copper oxide: 16 parts, aluminum oxide: 12 parts, acrylic emulsion: 31 parts, nitrile latex: 22 parts, polyurethane emulsion: 12 parts, alkyd resin: 14 parts, ethyl acetate : 23 parts, aliphatic sulfonate: 14 parts, paraffin: 2 parts, alkyl aryl sulfonate: 14 parts, PVC resin powder: 14 parts, talc: 16 parts, clay: 25 parts;

[0043] The preparation process of the corrosion-resistant high-strength coating is carried out in the following steps:

[0044] Step 1: Mix phyllite, lime alkali glaze,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com