Functional copper sulfide composition and functional fiber prepared from same

一种功能性纤维、硫化铜的技术,应用在硫化铜、硫酸铜、氯化铜等方向,能够解决导电性纤维无法同时满足抗菌治愈伤口、纤维颜色改变、传导性、耐洗涤性耐清洗性、耐久性耐湿性、耐碱性降低等问题,达到静电去除特性优秀、防止皮肤老化、耐碱性优秀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

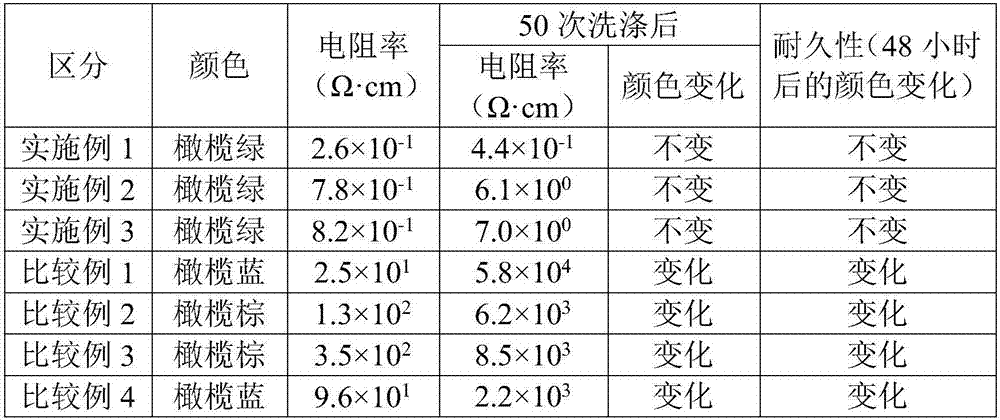

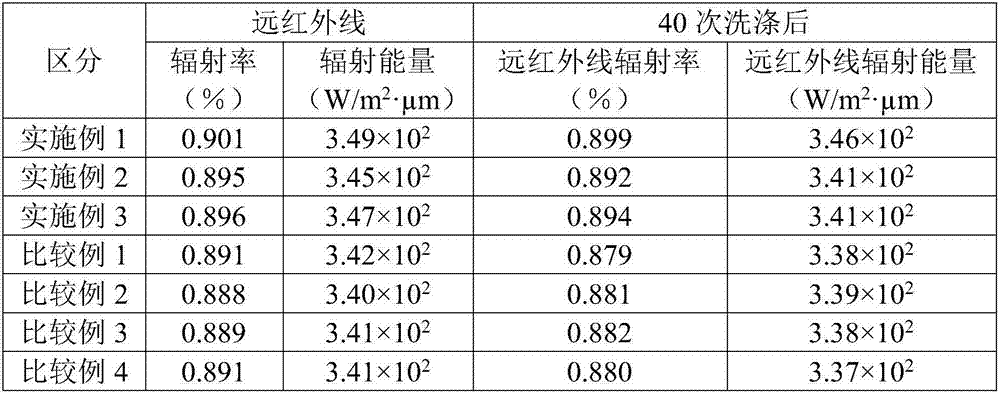

Examples

preparation example Construction

[0056] The present invention relates to a method for preparing functional fibers, which includes: the step of preparing a functional copper sulfide composition, the above-mentioned functional copper sulfide composition comprising 10-40% by weight of copper salt, 1-10% by weight of metal salt, 5-30 weight percent reducing agent, 5-30 weight percent sulfide, 1-5 weight percent catalyst, 1-10 weight percent polyvalent ammonium, 1-10 weight percent basic compound and 1-5 weight percent Percentage of pH regulator; the step of introducing functional groups, importing more than one fiber selected from vegetable fibers, animal fibers, synthetic fibers and regenerated fibers selected from thiol groups, thiocarbonyl groups, thiourea groups, and azole groups More than one functional group in amino group, cyano group and amide group; Coordination bond bonding step, the fiber introduced with functional group is processed by the above composition to bond with copper sulfide on the surface of...

Embodiment 1

[0084] By mixing 35% by weight of copper sulfate (II) pentahydrate, 5% by weight of silver nitrate, 20% by weight of ferrous sulfate, 20% by weight of sodium thiosulfate, 3% by weight of magnesium chloride, 7% by weight of three sub Methyldiamine, 7% by weight of sodium hydroxide and 3% by weight of citric acid were used to prepare a functional copper sulfide composition.

[0085] In an aqueous solution containing a silane coupling agent prepared by reacting imidazole and 3-mercaptopropyltrimethoxysilane, polyamide fibers were dipped and reacted at a temperature of 50°C for 60 minutes to prepare surface-treated polyamide fibers .

[0086] As a result of comparing the fiber weight before and after introducing the functional group to the surface of the fiber, the content of the functional group was 2.3% by weight based on the total fiber weight.

[0087] In an aqueous solution containing 60 parts by weight of the above-mentioned functional copper sulfide composition, 100 parts ...

Embodiment 2

[0091] Except by mixing 35% by weight of copper sulfate (II) pentahydrate, 5% by weight of silver nitrate, 20% by weight of ferrous sulfate, 22.5% by weight of sodium thiosulfate, 0.5% by weight of magnesium chloride, 7% by weight of Trimethylenediamine, 7% by weight of sodium hydroxide and 3% by weight of citric acid were used to prepare the functional copper sulfide composition, and the same method as in Example 1 was used to prepare functional polyamide fibers.

[0092] The content of copper sulfide was 9.8% by weight and the content of silver sulfide was 1.5% by weight relative to the total fiber weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com