Design for solid cells

A solid fuel cell and battery technology, applied in the direction of solid electrolyte, secondary battery, battery pack parts, etc., can solve the problems of high manufacturing cost and high cost, and achieve the effect of flexible wiring modification scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

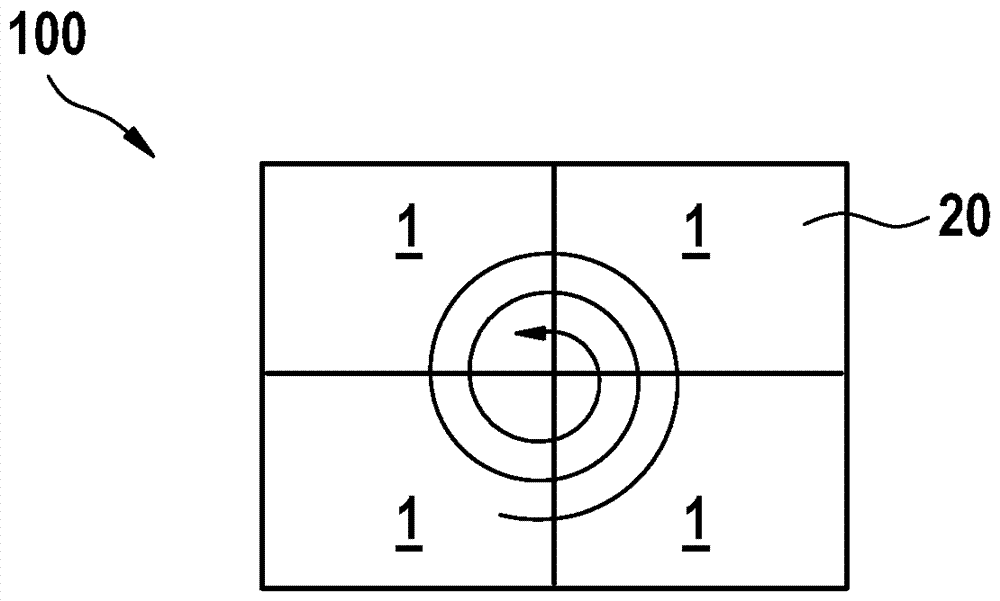

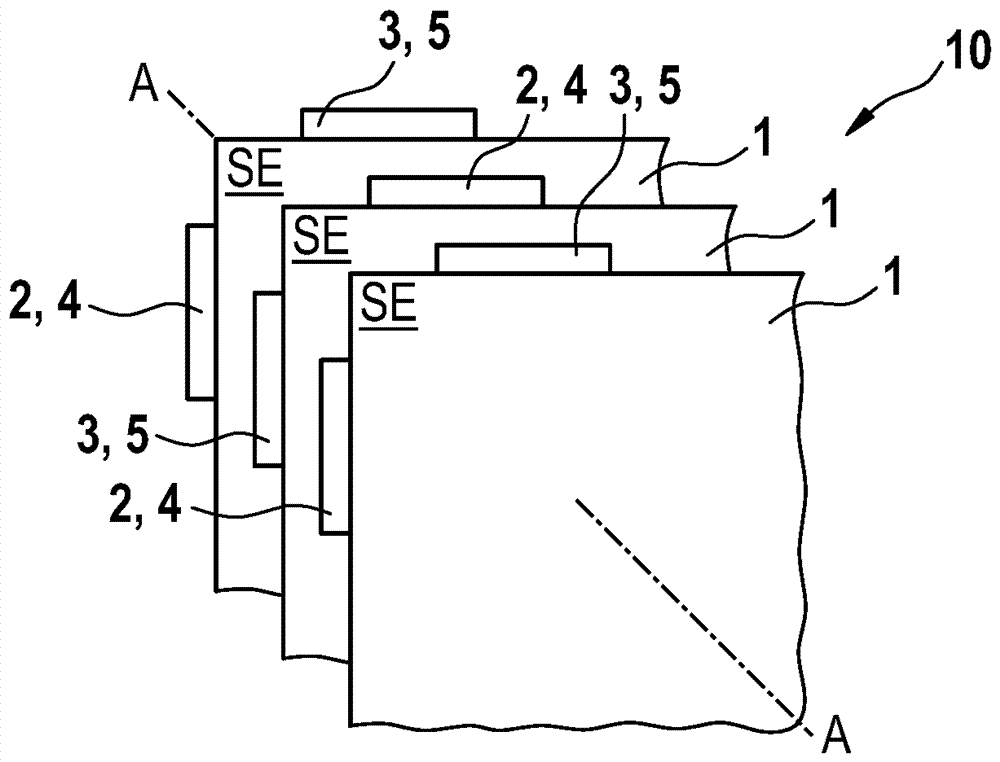

[0044] figure 1 A schematic view of a cell layer 1 , which is designed for the production of a solid fuel cell according to the method according to the invention, is shown in plan view on the plane of symmetry SE, the cell layer 1 having a first conductor layer 2 and a second conductor Layer 3. The first conductor layer 2 is separated from the second conductor layer 3 at least by an insulating layer, not shown here. Advantageously, the first conductor layer 2 is a cathode conductor layer, preferably made of aluminum foil. Advantageously, the second conductor layer 3 is an anode conductor layer, and the material of the anode conductor layer is copper foil or nickel foil. The first conductor layer 2 , here advantageously an aluminum foil, is formed as a current collector 4 in the form of a contact bump which is opposite to the current collector 4 formed by the second conductor layer 3 in the form of a contact bump. The current collectors 5 are arranged symmetrically with resp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap