Simple inner hexagonal bolt automatic paint dripping sleeve

A hexagonal bolt and paint spotting technology, which is applied to screwdrivers, devices for coating liquid on the surface, wrench, etc., can solve problems such as inability to store ink, poor paint spotting effect, and affect appearance, and achieve outstanding substantive features and Significant, achieve a large amount of storage, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

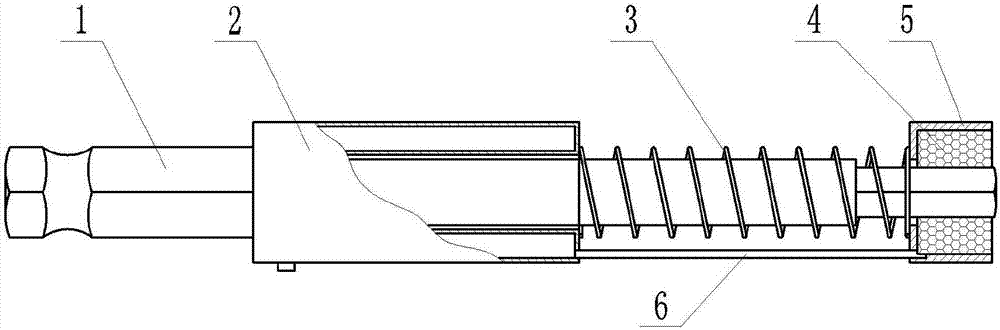

[0017] Such as figure 1 As shown, a simple hexagon socket bolt automatic paint spotting sleeve includes a hexagon socket rod 1, a liquid storage bottle 2, a spring 3, a felt 4, a paint spotting sheath 5 and an infusion tube 6; the liquid storage bottle 2 is A circular cylinder structure, the hole diameter of the middle part matches the inner hexagonal rod 1, and the liquid storage bottle 2 is inserted into the inner hexagonal rod 1 through the middle part and fastened with glue. The paint spotting sheath 5 is slidably combined at the lower end of the inner hexagon sleeve rod 1; the felt 4 is filled in the paint spotting sheath 5; the spring 3 is distributed between the liquid storage bottle 2 and the Between the paint sheaths 5, and the two ends of the spring 3 are combined with the liquid storage bottle 2 and the paint sheath 5 by glue; the spring 3 and the paint sheath 5 are formed into a whole, and rely on the said The support of the liquid storage bottle 2 is fixed, so th...

specific Embodiment 2

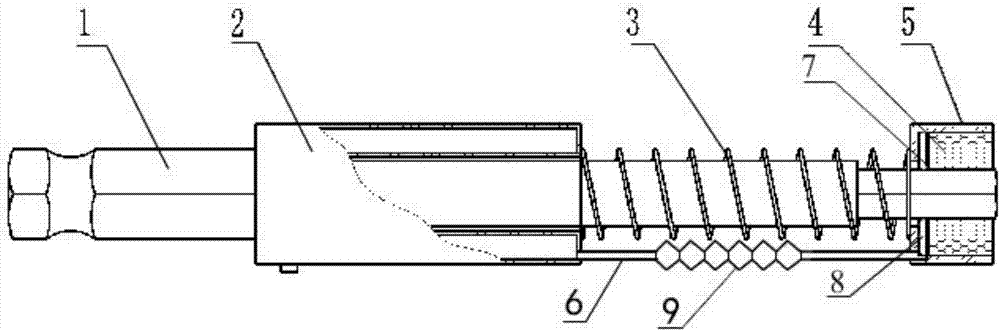

[0018] Such as figure 2 As shown, a simple hexagon socket bolt automatic paint spotting sleeve includes a hexagon socket rod 1, a liquid storage bottle 2, a spring 3, a felt 4, a paint spotting sheath 5 and an infusion tube 6; the liquid storage bottle 2 is A circular cylinder structure, the hole diameter of the middle part matches the inner hexagonal rod 1, and the liquid storage bottle 2 is inserted into the inner hexagonal rod 1 through the middle part and fastened with glue. The paint spotting sheath 5 can be slidably combined with the lower end of the inner hexagon sleeve rod 1; at the same time, a punching baffle 7 is also distributed on the upper part of the inner cavity of the paint spotting sheath 5 in this specific embodiment, and the punching An ink storage chamber 8 is formed between the hole baffle 7 and the top end of the paint spotting sheath 5 ; the felt 4 is distributed below the punching baffle 7 . The punching baffle 7 is used to block the felt 4 at its lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com