Silicon dioxide plated nanometer particle pinhole filling method

A nanoparticle, silicon dioxide technology, applied in Raman scattering, material excitation analysis, etc., can solve the problems of unsuitable SHINERS detection, reduced SHINERS activity, easy existence of pinholes in the shell, etc., to achieve mass storage and application. , The effect of effectively removing pinholes and low shell thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

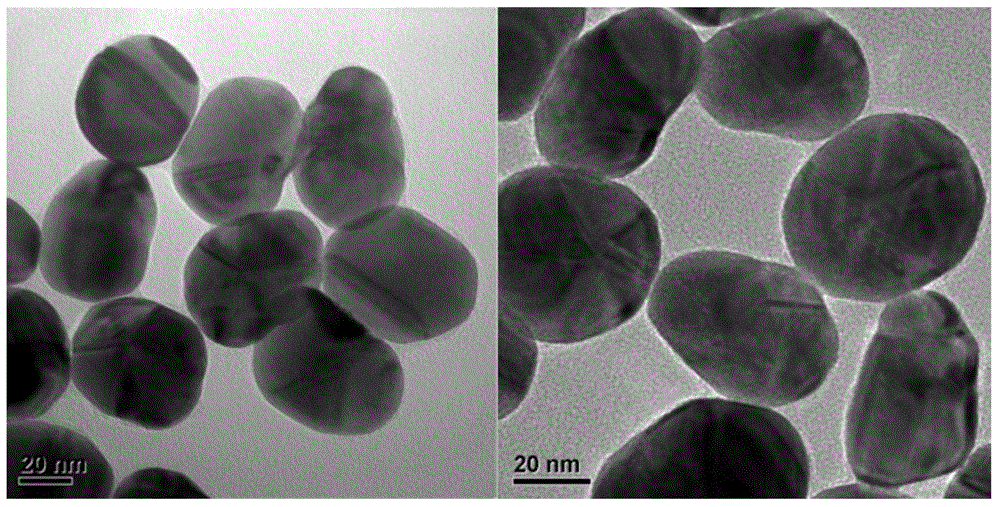

[0027] Take gold nanoparticles with a size of 55nm and a core-shell structure nanoparticle with a silica shell of 2nm as an example to fill pinholes.

[0028] Heat 100ml of chloroauric acid aqueous solution with a mass fraction of 0.01% to boiling, and quickly add 0.7ml of an aqueous solution of sodium citrate with a mass fraction of 1%. After about 2 to 3 minutes, the solution gradually turns from light yellow to black and then red Brown, continue to slightly boil for 40 minutes, stop the reaction, and cool to room temperature to obtain 55nm gold nanoparticles. Get 30ml 55nm gold nanoparticle sol, add 0.4ml 1mM 3-aminopropyltrimethoxysilane (APTMS) aqueous solution, stir for 15min, then add 3ml 0.54% sodium silicate solution, use 0.1M HCl solution to adjust the pH to 9.5, continue stirring for 3 minutes. Then place the reaction vessel in a water bath at 95°C and heat it for 20 minutes to obtain 55nm Au2nm SiO with pinholes 2 Nanoparticles. Take 10ml 55nm Au2nm SiO 2 The n...

Embodiment 2

[0030] Example 2 Nanoparticle pinhole detection

[0031] With different AuSiO 2 An example of Raman detection of 10mM pyridine on a nanoparticle-modified silicon wafer as a substrate.

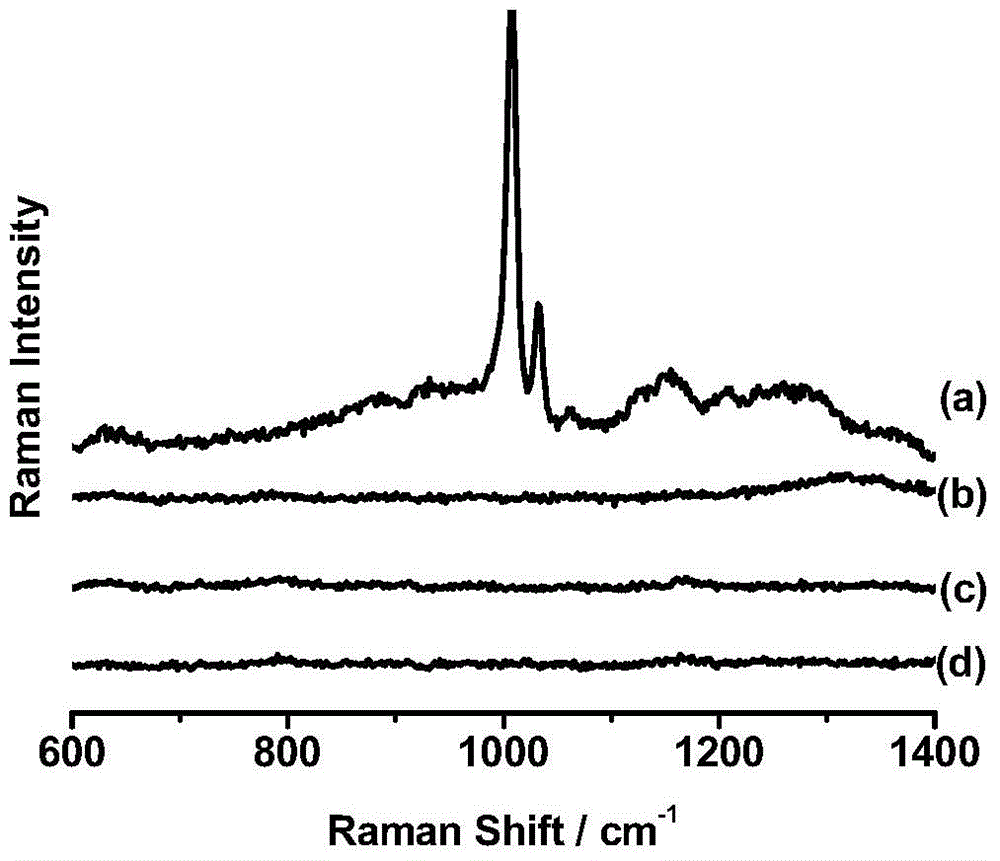

[0032] The centrifuged AuSiO 2Nanoparticles were added dropwise on a silicon wafer cleaned with a 3:1 mixed solution of concentrated sulfuric acid and hydrogen peroxide, and dried in vacuum to obtain a substrate sample. Add a drop of 10mM pyridine solution dropwise on the prepared sample, and test with a large-scale Raman tester to obtain the Raman signal of pyridine on the nanoparticle (see figure 2 ).

[0033] From figure 2 (a) It can be seen that in 55nm Au2nm SiO 2 A strong pyridine signal appeared on the nanoparticles, indicating that the nanoparticles were indeed pinholes. By joining S 2- After filling the pinhole, the pyridine signal disappeared immediately ( figure 2 b–d), showing that the pinholes have been filled with high efficiency.

Embodiment 3

[0034] Example 3 SHINERS Enhanced Detection

[0035] Take the SHINERS detection of pyridine on a smooth Ag electrode as an example.

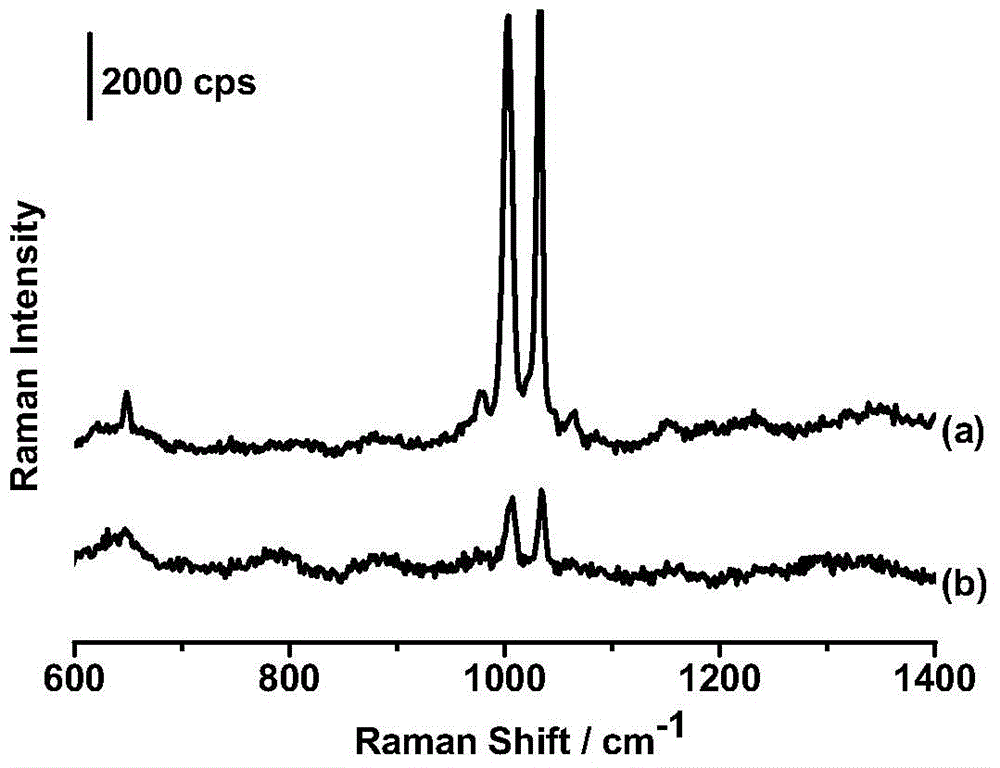

[0036] The different SHINERS nanoparticles after centrifugation were added dropwise on the smooth silver electrode and dried in vacuum; then the smooth silver electrode was placed in a Raman electrolytic cell containing 10mM pyridine, the selected laser power was 3mW, and the laser wavelength was 633nm. Get the SHINERS signal spectrum of pyridine on the smooth Ag electrode (see image 3 ).

[0037] It can be seen from the figure that 55nm Au2nm SiO filled with pinholes 2 Nanoparticles with pinhole-free 55nm Au4nm SiO 2 The SHINERS activity of nanoparticles is different. The signal intensity of the former is about 6-7 times higher than that of the latter, and the thickness of the shell is consistent with the reflected signal intensity, which fully proves that the use of S 2- Feasibility of filling the pinhole method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com