Glass grabbing device and grabbing method

A glass and grasping unit technology, applied in the direction of manufacturing tools, chucks, program-controlled manipulators, etc., can solve the problems of production troubles, the inability to turn over the original glass sheet freely, etc., and achieve the effect of easy grasping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

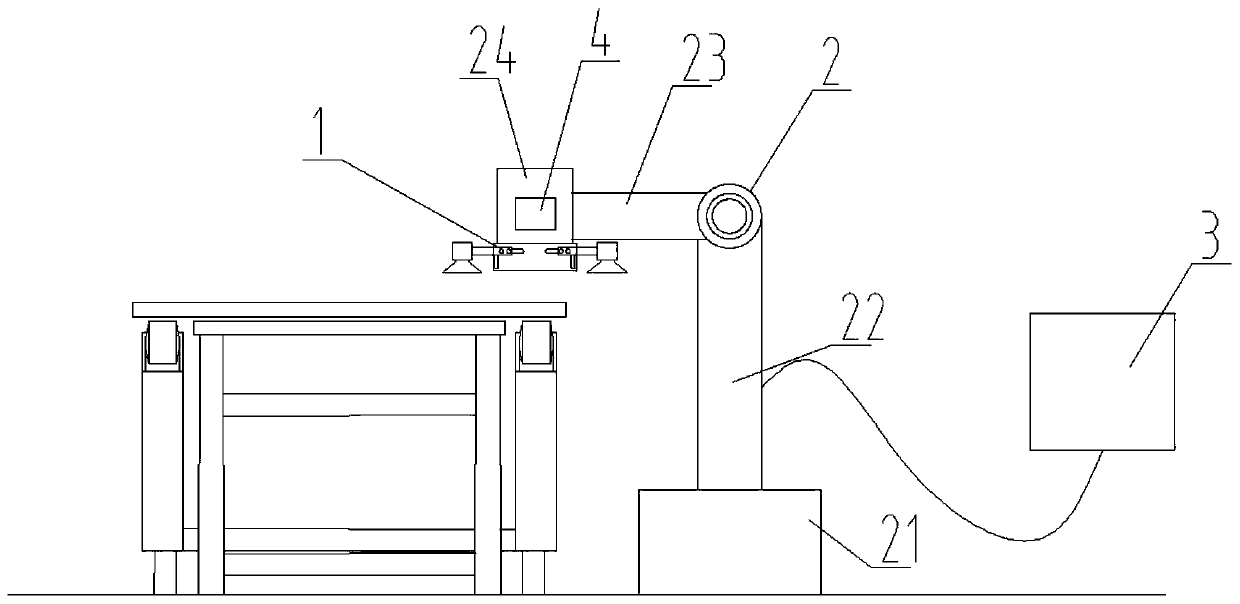

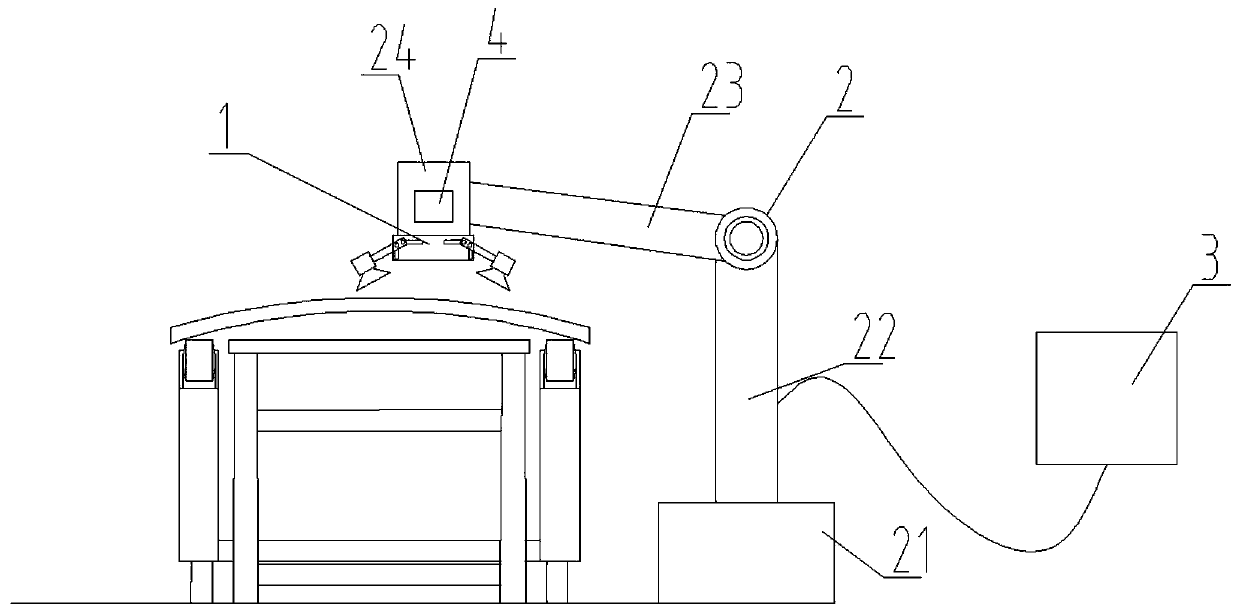

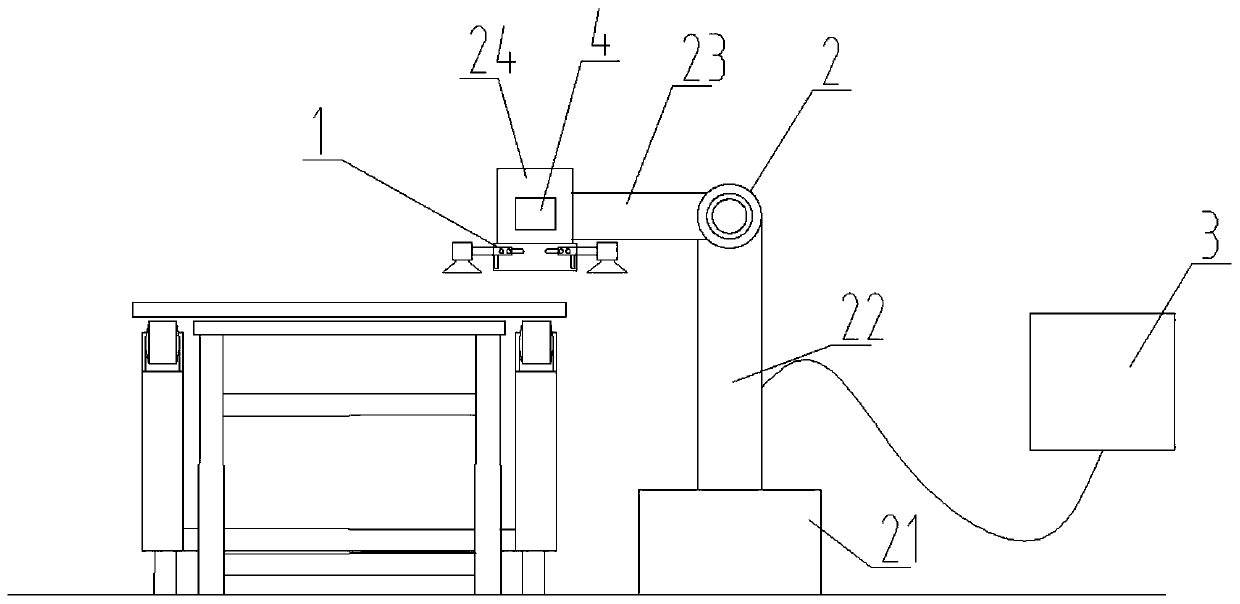

[0027] The invention relates to a glass grabbing device, the structural diagram of which is as follows figure 1 As shown, it includes a grabbing unit 1 , a moving unit 2 , a processing unit 3 , and an image capturing unit 4 .

[0028] The mobile unit 2 is fixed on the ground, the grasping unit 1 is fixedly connected with the mobile unit 2, the grasping unit 1 is used to grasp glass, and the mobile unit 2 is used to adjust the grasping unit 1; the image capture unit 4 is arranged on the capture unit 1, and the image capture unit 4 collects data such as the position of the original glass sheet, and transmits the data to the processing unit 3 The processing unit 3 is connected with the grabbing unit 1, the moving unit 2 and the image capturing unit 4 data, and the processing unit 3 processes the data collected by the image capturing unit 4, and the The moving unit 2 and the grabbing unit 1 issue instructions, and the moving unit 2 and the grabbing unit 1 perform grabbing operati...

Embodiment 2

[0034] The invention relates to a grabbing method for the glass grabbing device, the steps are specifically:

[0035] S1, read the data of the original glass sheet to be captured by the image capture unit 4, and transmit the data to the processing unit 3;

[0036] S2, through the calculation of the processing unit 3, control the moving unit 2 and the grabbing unit 1 to grab the original glass sheet;

[0037] S3, placing the original glass sheet at a designated position through the movement of the mobile unit 2;

[0038] Step S1 is specifically to move the grasping unit 1 to the position directly above the original glass sheet, the position is a fixed position, which is set by the processing unit 3, and generally is the transportation or support of the original glass sheet to be grasped. In the central position of the platform, a mesh pattern of square grids of equal size is set on the transport or support platform, the grid size is generally 5mmx5mm, the image capture device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com