Adjustment method of diamond-shaped reverse nine-spot well pattern in multi-layer low-permeability sandstone reservoir during high water-cut period

A technology for sandstone oil reservoirs and high water-cut periods, which is used in earth-moving drilling, wellbore/well components, and production fluids. Achieve the effect of increasing oil production rate and improving oil well production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

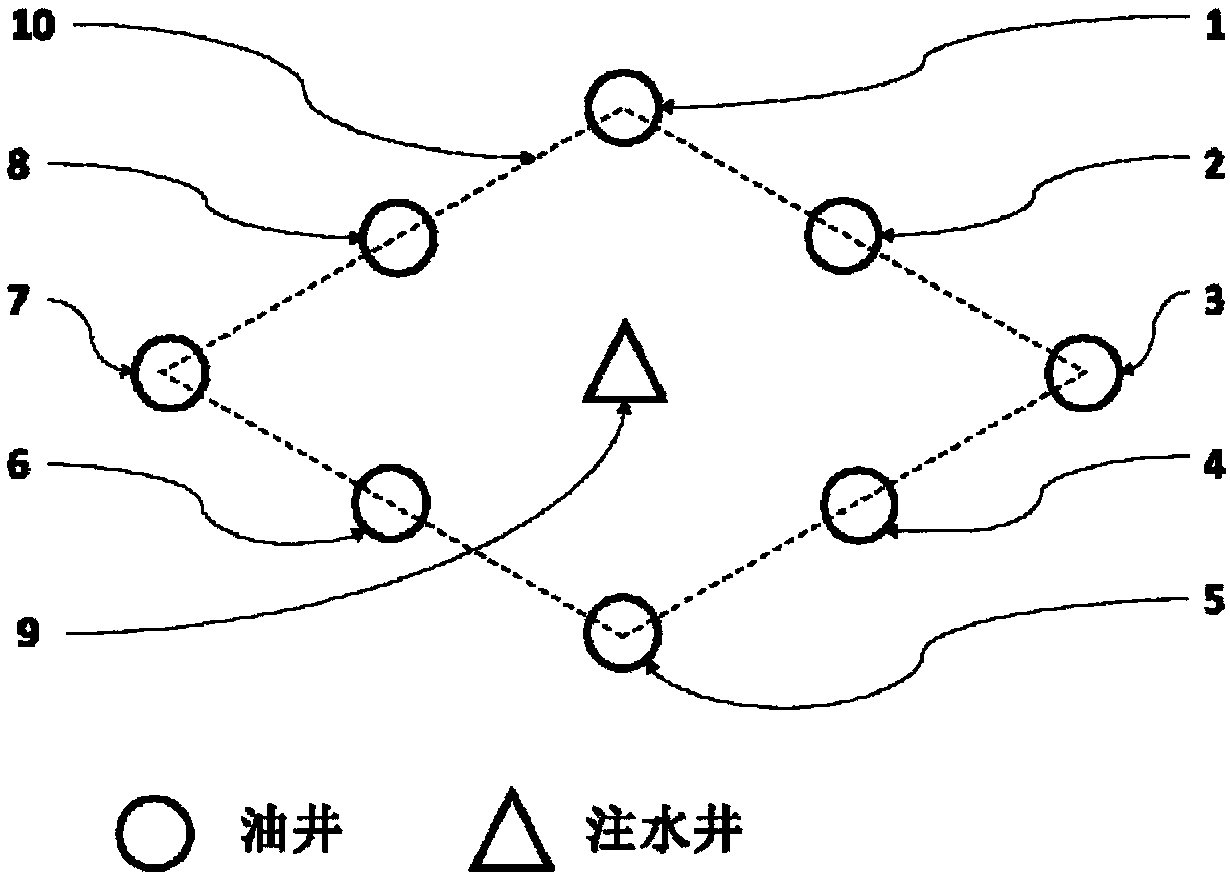

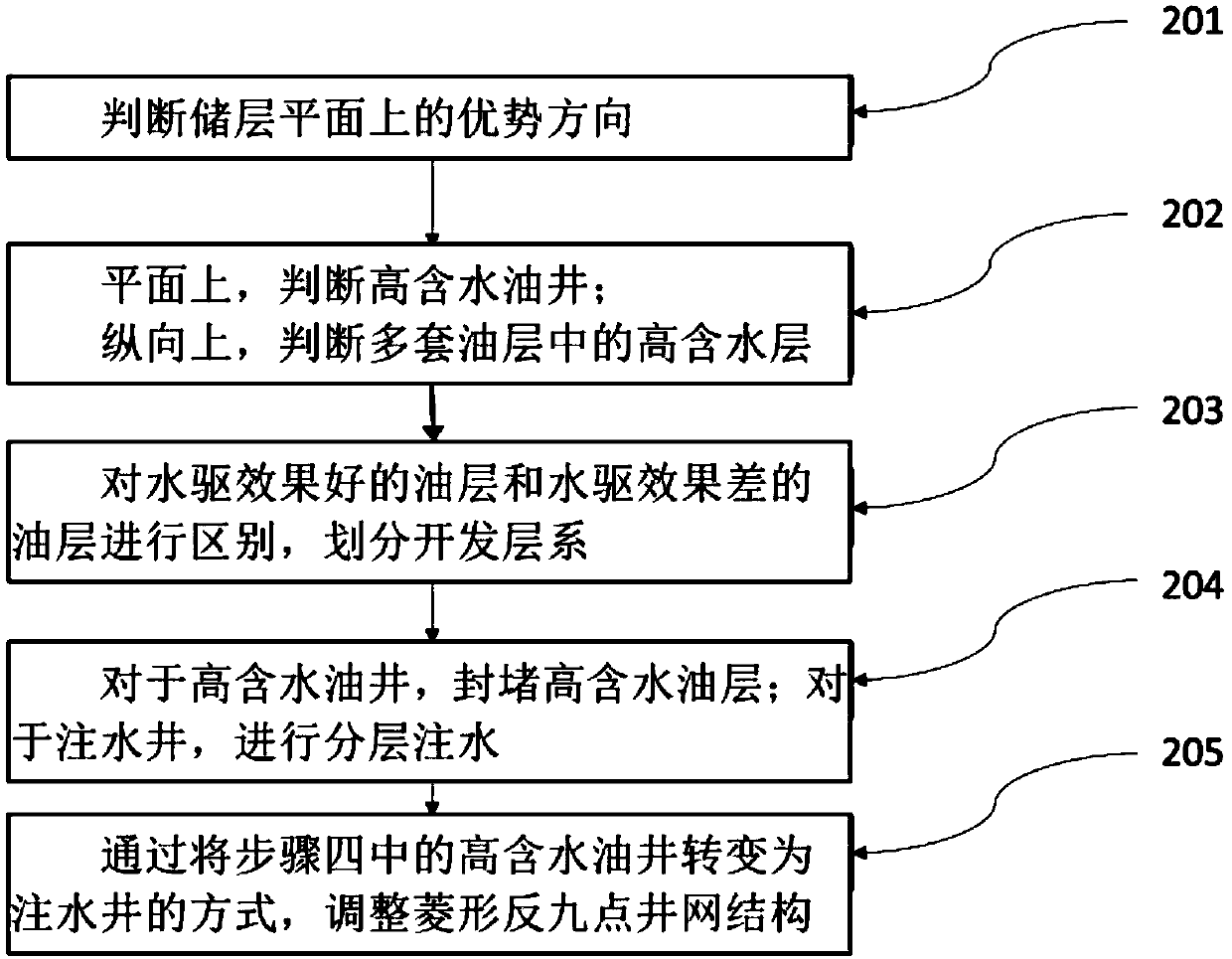

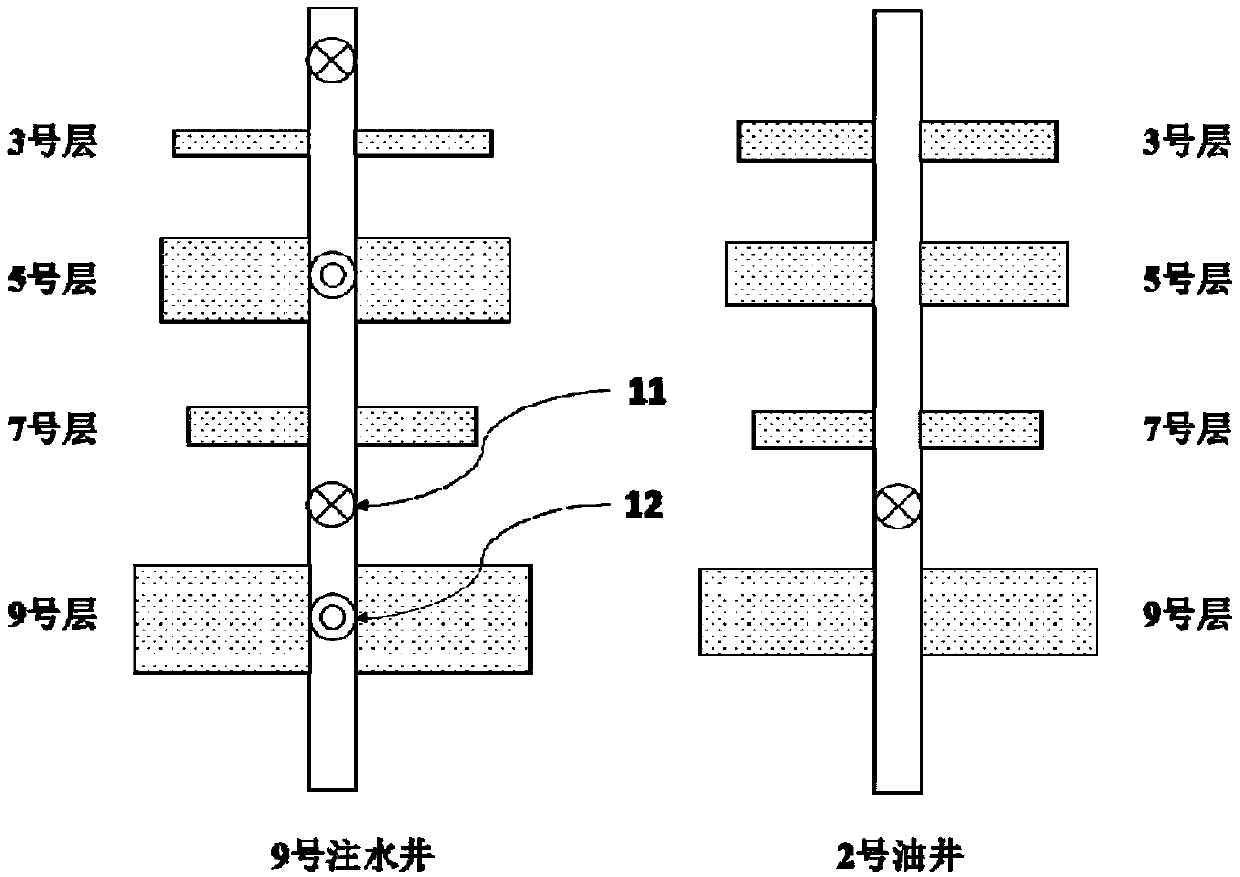

[0035] This embodiment provides a specific implementation process of an adjustment method for a diamond-shaped reverse nine-point well pattern in a multi-layer low-permeability sandstone reservoir during a high water-cut period. Such as figure 2 It is a flow chart of the method for adjusting the rhombus reverse nine-point well pattern in this embodiment.

[0036] In step 201, determine the dominant direction on the reservoir plane; the specific process is:

[0037] Based on sand body thickness distribution data, reservoir permeability anisotropy data, natural fracture data from core observation, artificial fracture azimuth monitoring and dynamic analysis, etc., the dominant direction on the reservoir plane is judged.

[0038] The direction in which the thickness of the sand body is basically the same is the dominant direction on the reservoir plane; on the contrary, the direction perpendicular to this direction is the non-dominant direction on the reservoir plane.

[0039] ...

Embodiment 2

[0059] This embodiment provides a specific implementation process of an adjustment method for a diamond-shaped reverse nine-point well pattern in a multi-layer low-permeability sandstone reservoir during a high water-cut period. figure 2 The flow chart of is also applicable to this embodiment.

[0060] In step 201, by using the permeability anisotropy data and the dynamic analysis method, it is determined that the angle between the dominant direction of the reservoir and the long diagonal of the rhombus is greater than 0.5 arctan (2b / a) and less than 1.5 arctan (2b / a), That is to say, the dominant direction of the reservoir is basically the same as that of the line connecting Well No. 6 and Well No. 2. The process goes to step 202.

[0061] In step 202, the water cut of No. 1 oil well is 58%, the water cut of No. 2 oil well is 70%, the water cut of No. 3 oil well is 58%, the water cut of No. 4 oil well is 58%, and the water cut of No. 5 oil well It is 58%, the water cut of ...

Embodiment 3

[0066] This embodiment provides a specific implementation process of an adjustment method for a diamond-shaped reverse nine-point well pattern in a multi-layer low-permeability sandstone reservoir during a high water-cut period. figure 2 The flow chart of is also applicable to this embodiment.

[0067] In step 201, through the permeability anisotropy data and dynamic analysis method, it is determined that the angle between the dominant direction of the reservoir and the long diagonal of the rhombus is greater than [180°-1.5arctan(2b / a)] and less than [180°- 0.5arctan(2b / a)], that is, the dominant direction of the reservoir is basically the same as that of the line connecting Well No. 8 and Well No. 4. The process goes to step 202.

[0068] In step 202, the water cut of No. 1 oil well is 58%, the water cut of No. 2 oil well is 58%, the water cut of No. 3 oil well is 58%, the water cut of No. 4 oil well is 70%, and the water cut of No. 5 oil well It is 58%, the water cut of N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com