A steam-cooled tube screen flue and its supporting and hanging structure

A technology of steam-cooled tube and tube screen, which is applied in the field of steam-cooled tube screen flue and its supporting and hanging structure, can solve the problems of difficulty in supporting and hanging the gas-cooled tube screen flue, and solve the problem of the unity of the direction of free expansion due to heating. , The effect of solving the problem of supporting and hanging, saving layout space and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

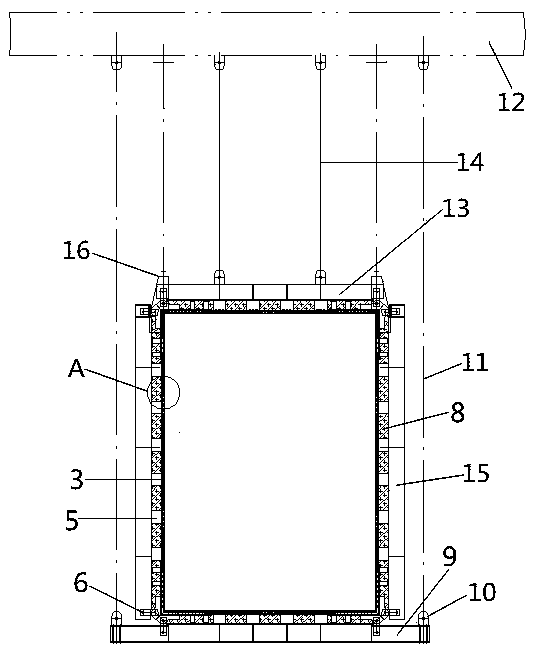

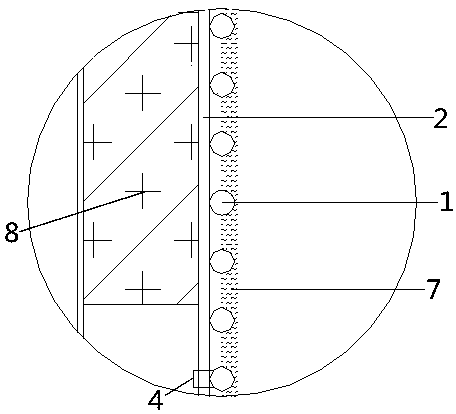

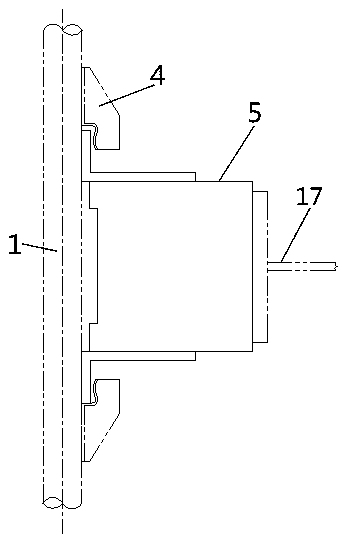

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] like figure 1 , figure 2 , image 3 As shown, the steam-cooled tube panel flue of the present invention includes a rectangular tube panel flue 3 welded by steam pipes 1 and fins 2, along the axis of the tube panel flue 3 at the center of the tube panel flue 3 At least one rigid beam 17 perpendicular to the axis of the tube panel flue 3 is arranged on the two side surfaces and the top and bottom surfaces, and the rigid beams 17 on each surface are distributed at even intervals, and are arranged on the tube panel flue 33 All the surrounding rigid beams 17 are slidably connected with the tube panel flue 3 through several lugs 4 fixed on the tube panel flue 3 and the connecting pieces 5 slidingly connected with the lugs 4 , and the lugs 4 and its sliding The connected connectors 5 are evenly spaced along the length direction of the rigid beam 17,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com