Multifunctional fresh air exchanger

A switch and multi-functional technology, which is applied in the field of multi-functional fresh air switches, can solve the problems of single operating mode of fresh air switches and cannot meet the diversified needs of customers, and achieve effective adjustment of indoor comfort, meet diversified needs, and flexible operating modes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

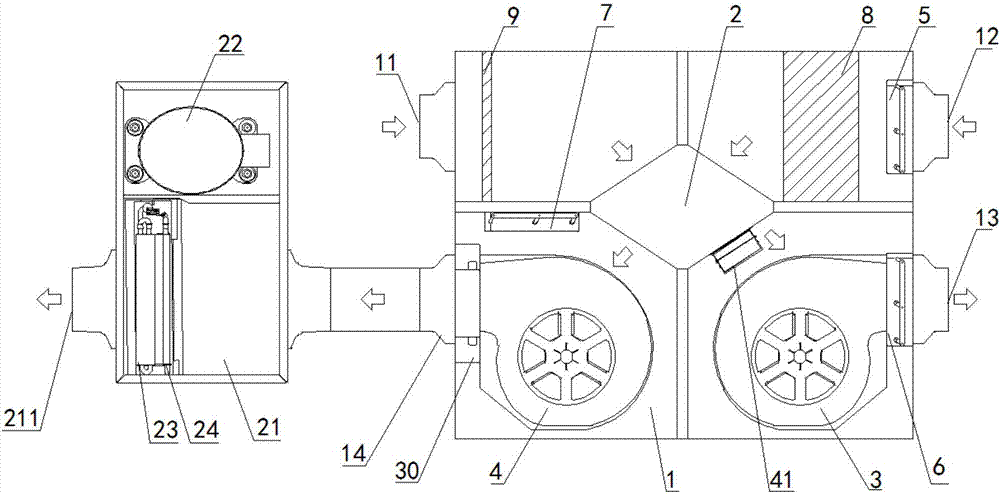

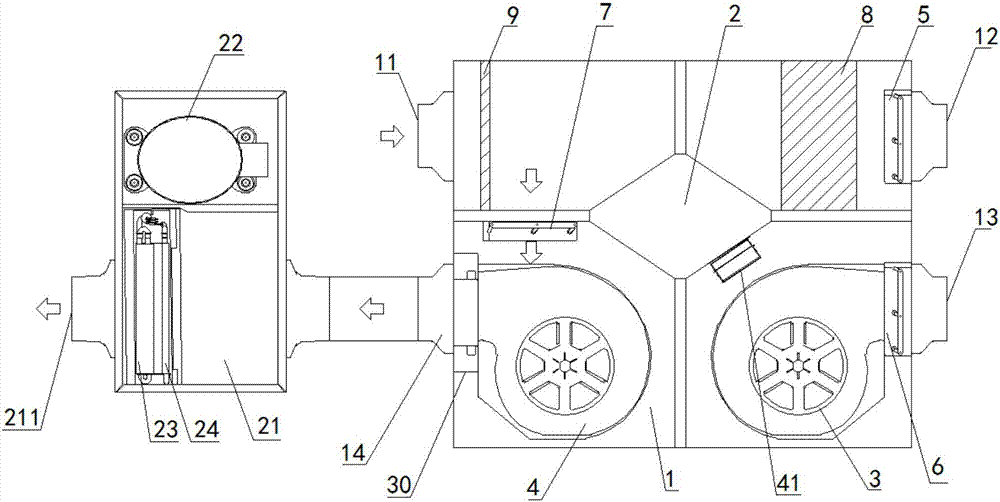

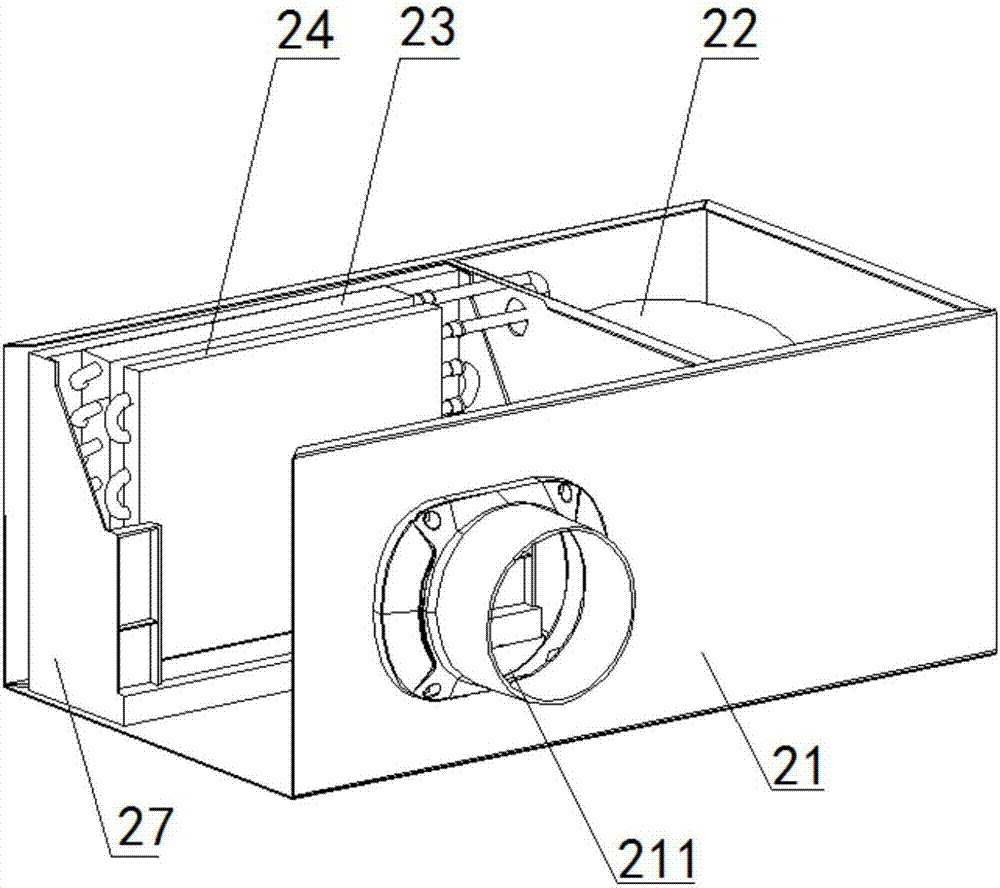

[0025] Such as figure 1 with figure 2 As shown, figure 1 It is a schematic diagram of the structure of the multifunctional fresh air switch of the present invention and an air flow diagram in a conventional mode; figure 2 It is a schematic diagram of the structure of the multifunctional fresh air switch and the air flow diagram in the dehumidification and heating mode of the present invention. A multifunctional fresh air switch includes a fresh air mechanism and a dehumidification mechanism. The dehumidification mechanism and the fresh air mechanism are connected through pipelines. The fresh air mechanism is provided with a bypass device and a heating device 30.

[0026] Specifically, the fresh air mechanism includes a box body 1, a heat exchange core body 2, an exhaust fan 3, a blower 4, a fresh air isolation valve 5, an exhaust air isolation valve 6, an internal circulation air valve 7, a fresh air filter 8 and a return air filter. 器9; The heat exchange core 2 is set in the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com